- Systems

-

Products

- Traffic Bearing Waterproofing Coating

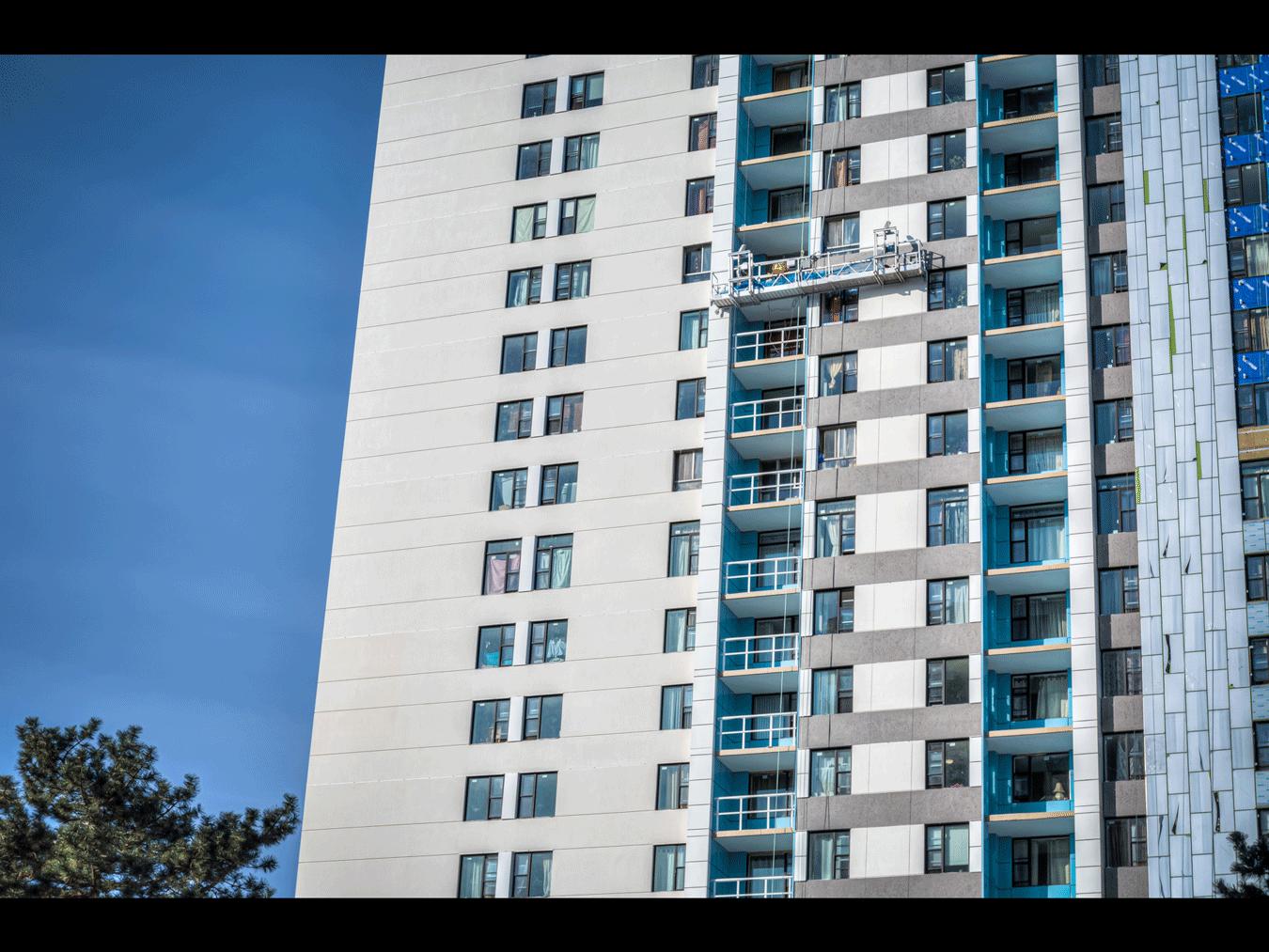

- Balcony & Pedestrian Waterproofing

- PMMA Based Traffic Waterproofing

- Cementitious Polyurethane Flooring

- Epoxy Floor Coatings

- Heavy Duty Epoxy Flooring

- Interior Decorative Resinous Flooring

- Exterior Decorative Resinous Flooring

- Electrostatic Discharge (ESD) Flooring

- Chemical Resistant Epoxy

- Floor Top Coats

- Floor Primers

- Floor Accessories

- Leveling & Repair Mortars

- Tools & Resources

- Gallery

- Contact