Dur-A-Hard SL Self-Leveling Cementitious Polyurethane Flooring System is a pourable, phthalate & solvent-free, cementitious polyurethane floor topping system designed to provide a tough and durable, non-slip textured surface for wet and dry production areas predominately in the food and beverage industry.

- CFIA approved; USDA accepted

- Zero VOCs, odorless, and non-tainting

- Resistant to organic and inorganic chemical compounds and bacterial growth

- Chemical and abrasion resistant

- Thermal shock resistant and Wide Service Temperature Range (-10oC to 120oC)

- Easy to apply, easy to clean and sterilize

- May be applied at low temperatures (5°C)

- Seamless waterproof slip-resistant floor topping

- Will bond to mild steel and water-resistant plywood

Dur-A-Hard SL Self-Leveling Cementitious Polyurethane Flooring System is a squeegee-applied, odourless, 1/8” – 1/4” self-leveling flooring system approved for use in the food and beverage industry. Dur-A-Hard SL Self-Leveling Cementitious Polyurethane Flooring System is designed to protect concrete floor surfaces against organic and inorganic chemical compounds and bacterial growth, and withstands thermal shock under extreme cold and heat steam treatments. Dur-A-Hard SL Self-Leveling Cementitious Polyurethane Flooring System is ideal for pharmaceutical laboratories and clean rooms, chemical processing plants and containment storage rooms, production processes exposed to aggressive chemicals, food processing plants, including meat/poulty processing, bakeries and dairy manufacturing. It is also used for hospitals and medical centres, commercial kitchens, wet ares, loading docks, garbage rooms and wet and high-impact areas.

| Colour | Please see Durex® Colour Selection Guide for available colour options |

|

| Adhesion to Concrete | >400 psi (concrete fails before loss of bond) |

|

| Cure Time @ 21°C | Foot Traffic: 12-14 hours |

|

| Mix Ratio (By Volume) | 4 Component Kit |

|

| Coverage per Kit | 2.8 m2 @ 3 mm (30 ft2 @ 1/8 in) / |

|

| Pot Life  working time @ 21°C | 20 minutes Note: Pot life is shorter at higher temperatures. Do not use below 5°C or |

|

| Service Temperature | -10°C to 120°C (steam wash) |

| Abrasion Resistance | ASTM C501 CS17 Wheel 1000 GM |

35 mg loss |

|

| Coefficient of Friction Standard Slip-Resistant | ASTM D2047 |

0.9 |

|

| Compressive Strength | ASTM C579 |

52 MPa (7,560 psi) |

|

| Flexural Strength | ASTM C580 |

20 MPa (2,908 psi) |

|

| Impact Resistance @ 125 mils | MIL D3134 |

Pass |

|

| Tensile Strength | ASTM C307 |

52 MPa (7,560 psi) |

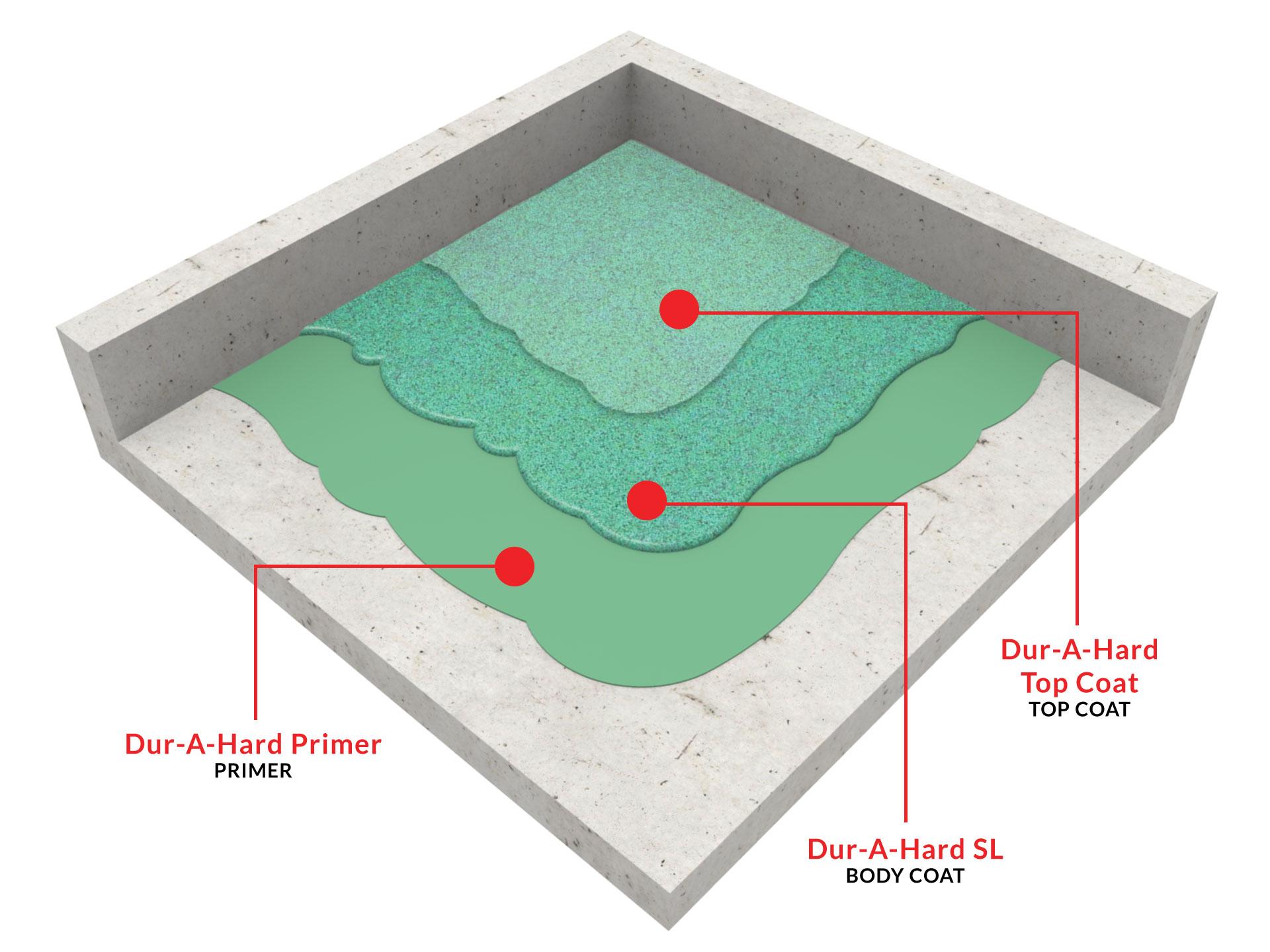

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional |

|

| Top Coat |