Duracrete Broadcast System is a high build, heavy duty, single colour, aggregate filled epoxy flooring system designed to protect concrete floors from heavy wear, impact, abrasion and mild chemicals in institutional, commercial and industrial environments. Installed at 80-120 mils (2-3mm), Duracrete Broadcast System offers excellent abrasion resistance for demanding floor areas.

- High performance durable floor

- Easy and quick to install

- 100% solids, zero VOC

- Will not support growth of fungus or bacteria

- Excellent abrasion and slip resistance

- Easy to clean and to maintain

- CFIA Approved & USDA compliant for use in federally inspected meat and poultry plants

Duracrete Broadcast System is used to protect concrete which will be exposed to heavy mechanical abuse and mild chemical attack while providing aggressive slip resistance for added safety. It is best used for heavy traffic industrial, commercial and industrial flooring applications where high abrasion resistance and durability is required. Duracrete Broadcast System is ideal for high traffic areas and corridors, garbage rooms, production and assembly floors, heavy duty manufacturing, food processing plants, shower rooms, lockers, service bays and warehouse floors where protection from mechanical abuse is desired and chemical exposure is limited.

| Colour | Please see Durex® Colour Selection Guide for available colour options. |

|

| Resin Type | Primer: Epotel Multi-Prime Broadcast (Epotel GSC + Silica Sand) Epotel GSC - Silica Sand #32 or #16 Topcoat: Epotel GSC |

5 m2/L (200 ft2/gal) @ 8 mils - 0.9 m2/L (36 ft2/gal) @ 35 mils DFT - 5-10 kg/m2 (1-2 lb/ft2) 2-3 m2/L (80-160 ft2/gal) @10-20 mils DFT |

| Mix Ratio | 2:1 by volume |

|

| Pot Life @ 23°C | 25 minutes (Epotel GSC) |

|

| Service Temperature Range | Min. 0°C/Max. 50°C/Quick Term 95°C |

| Compressive Strength @ 7 days | ASTM C 579 |

10,500 psi |

|

| Tensile Strength | ASTM C 307 |

2,100 psi |

|

| Flexural Strength | ASTM C 580 |

850 psi |

|

| Bond Strength | ACI 503R |

350 psi concrete fails |

|

| Thermal Coefficient of Expansion | ASTM D 696 |

0.000635 mm/inch per 0°C |

|

| Abrasion Resistance CS-17 wheel, 1 kg. load, 1000 rev. | ASTM D 4060 |

35-45 mg maximum weight loss |

|

| Thermal Shock Resistance | ASTM C 884 |

Passes |

|

| Water Absorption | ASTM C 413 |

0.1% |

|

| Flammability | ASTM D 635 |

Self-extinguishing |

|

| Impact Resistance | MIL D-3134F |

1.5 ft/lb |

|

| Indentation | MIL D-3134F |

3.6% |

|

| Coefficient of Friction | ANSI A137.1 / ANSI A326.3 |

0.73 WET |

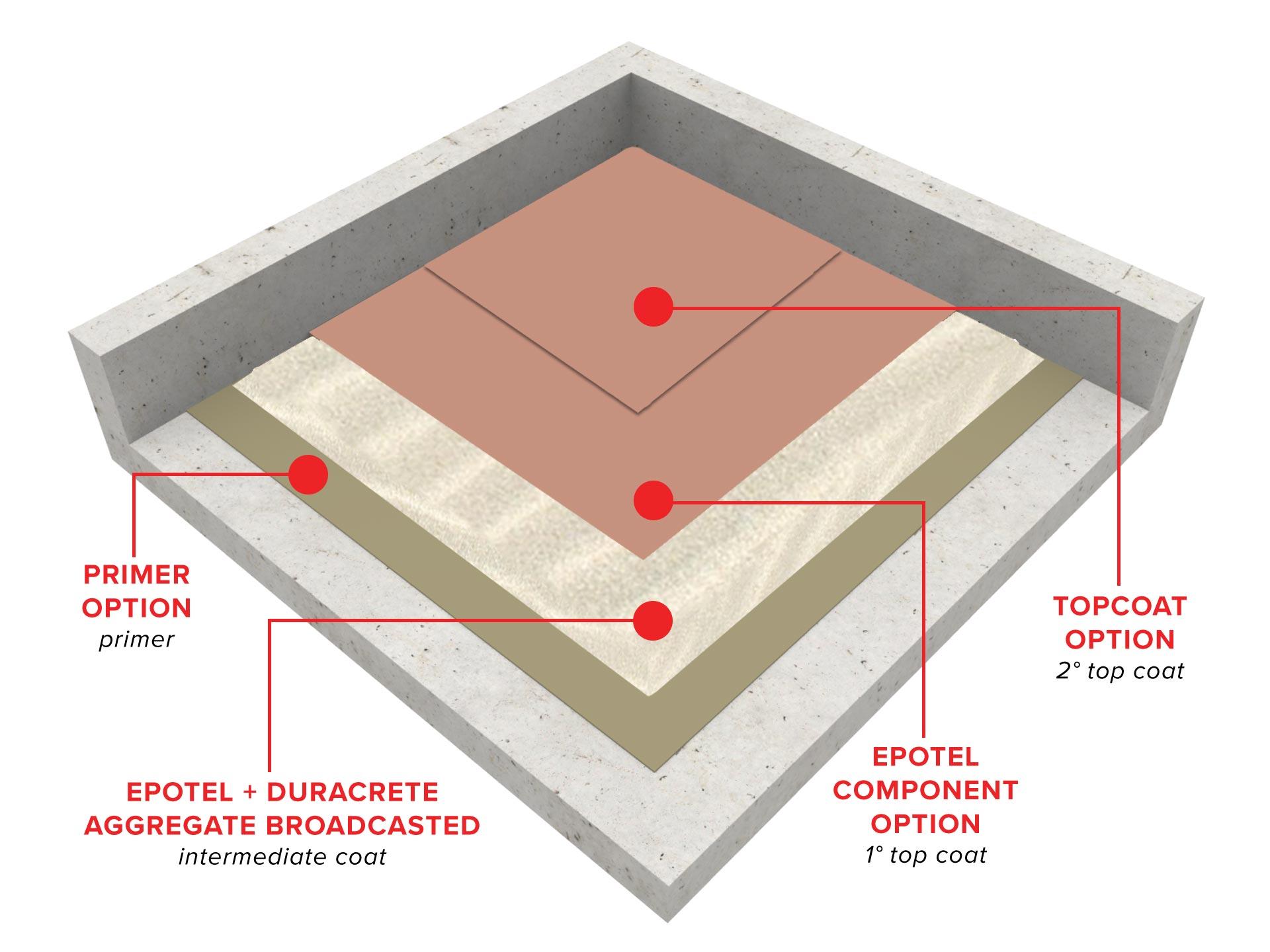

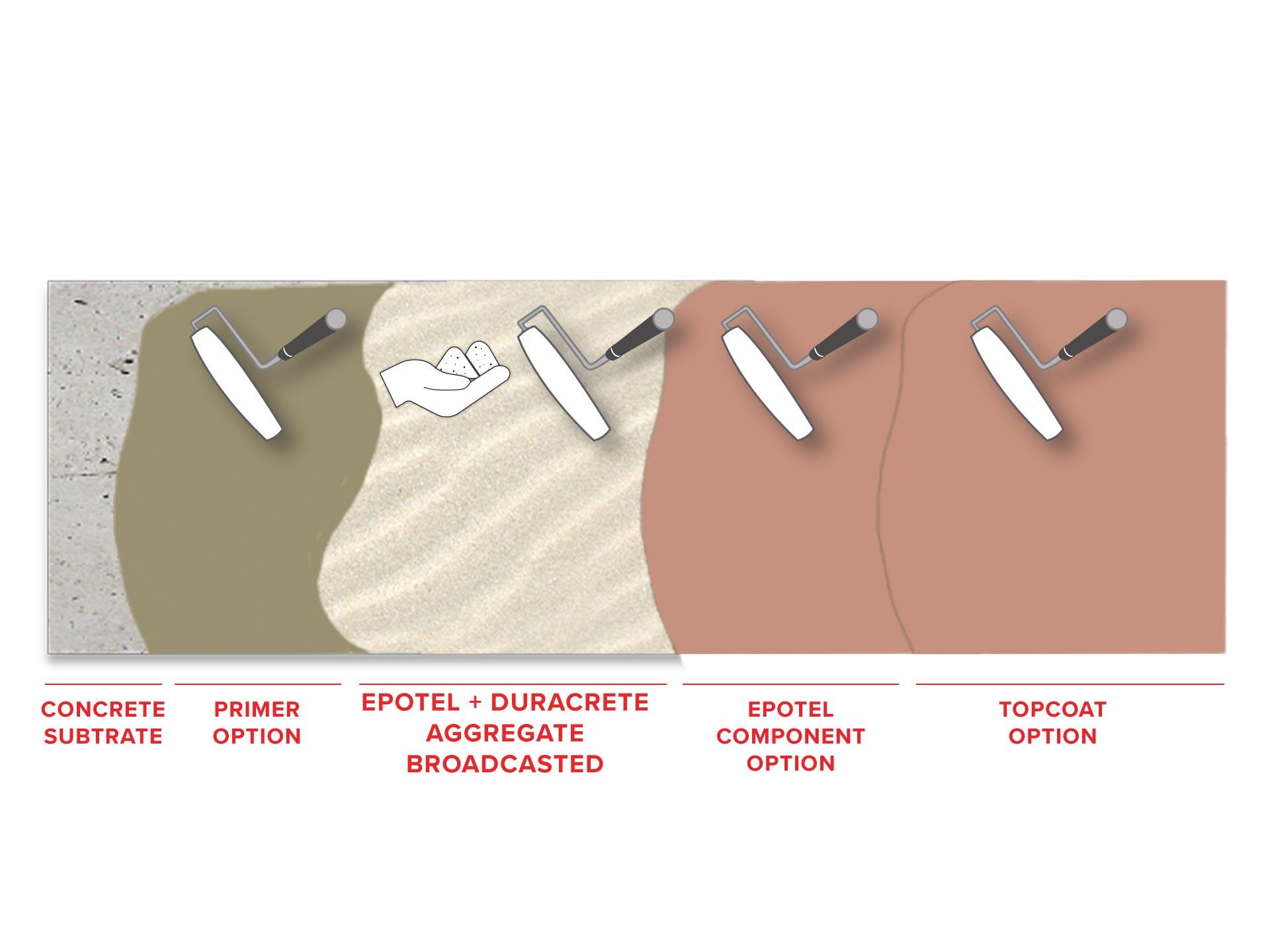

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | ||

| Primer | Optional Optional Optional |

|

| Intermediate Coat | + Broadcast Sand Aggregate (Optional) + Broadcast Sand Aggregate (Optional) + Broadcast Sand Aggregate (Optional) + Broadcast Sand Aggregate |

|

| Top Coat | Optional Optional Optional |

|

| Polyurethane Top Coat | Optional Optional Optional |