Durex® Uraflex 100 Flexible Industrial Floor Coating is a 100% solids, two-component polyurethane protective industrial floor coating typically used in combination with anti-slip aggregates for a textured finish. It is specially formulated to perform where low temperature, flexibility, abrasion and chemical resistance are required. This product has excellent chemical properties which make it an extremely versatile coating that outperforms standard epoxy coatings in regards to flexibility and abrasion resistance.

- Excellent adhesion to a variety of substrates

- Outstanding stability at low temperatures

- Zero VOC, 100% solid urethane

- Excellent moisture resistance

- Bonds to metal

- Orange peel finish

- Abrasion resistant

- Penetrates and seals the surface

- Can be applied on walls > 250 microns thickness

- Canadian Food Inspection Agency approved, USDA accepted

Durex® Uraflex 100 Flexible Industrial Floor Coating is used in a variety of interior protective floor-coating applications. To be used in combination with an anti-slip aggregate for a textured finish. Also used as a protective wall coating.

| Colour | Pigmented |

|

| Mix Ratio | Part A (Resin):Part B (Urethane) Mix as per kit |

|

| Cure Time @ 23ÃÂðC (75ÃÂðF) | To touch: 6 hours To recoat: 6 hours To traffic: 48 hours Fully cured: 4 days |

|

| Coverage | 4 m2/L (160 ft2/US gal) @ 10 mils |

|

| Recommended Film Thickness | 5 mils (75 microns) min to 20 mils (500 microns) max |

|

| Pot Life âÃÂàworking time @ 23ÃÂðC (75ÃÂðF) | 20 minutes |

|

| Reducer / Clean Up | Lacquer thinner or IPA |

|

| VOC | Zero |

| Percent Solids | ASTM D7232-06 |

100% |

|

| Viscosity (Brookfield) 23ÃÂðC (75ÃÂðF) | ASTM D2196 |

2,500 cps |

|

| Abrasion Resistance | ASTM 5178-91, CS-17 wheel |

20 mg loss @ 1000 g load, 1000 cycles |

|

| Tensile Strength | ASTM D412 |

2,700 psi |

|

| Specific Gravity | ASTM D333 |

1.1-1.2 g/L (8.9-10 lb/gal) |

|

| Elongation | ASTM D412 |

45% |

|

| Low Temperature Flexibility | 1/8” Mandrel Bend @ -26C |

Pass |

|

| Tear Strength | ASTM D624 Die C |

171 lb./In. inch (30KN/linear metre) |

|

| Adhesion to Concrete | ASTM C794 |

> 350 psi (2.4 MPa): Concrete Fails |

|

| Shore Hardness A | ASTM C661-83 |

95 |

|

| Water Swelling | 6 hours |

0.05 (max % weight gain) |

|

| Water Vapour Transmission | ASTM E96 – Procedure B |

0.05 grain/hr∙pi2 0.029 g/hr∙m2 |

|

| Water Vapour Permeability | ASTM E96 |

0.20 Perm In. 0.0025 ng/Pa∙s∙m2 |

|

| Water Vapour Permeance | ASTM E96 |

4.70 x 10 – 5 perm 0.028 ng/Pa∙s∙m2 |

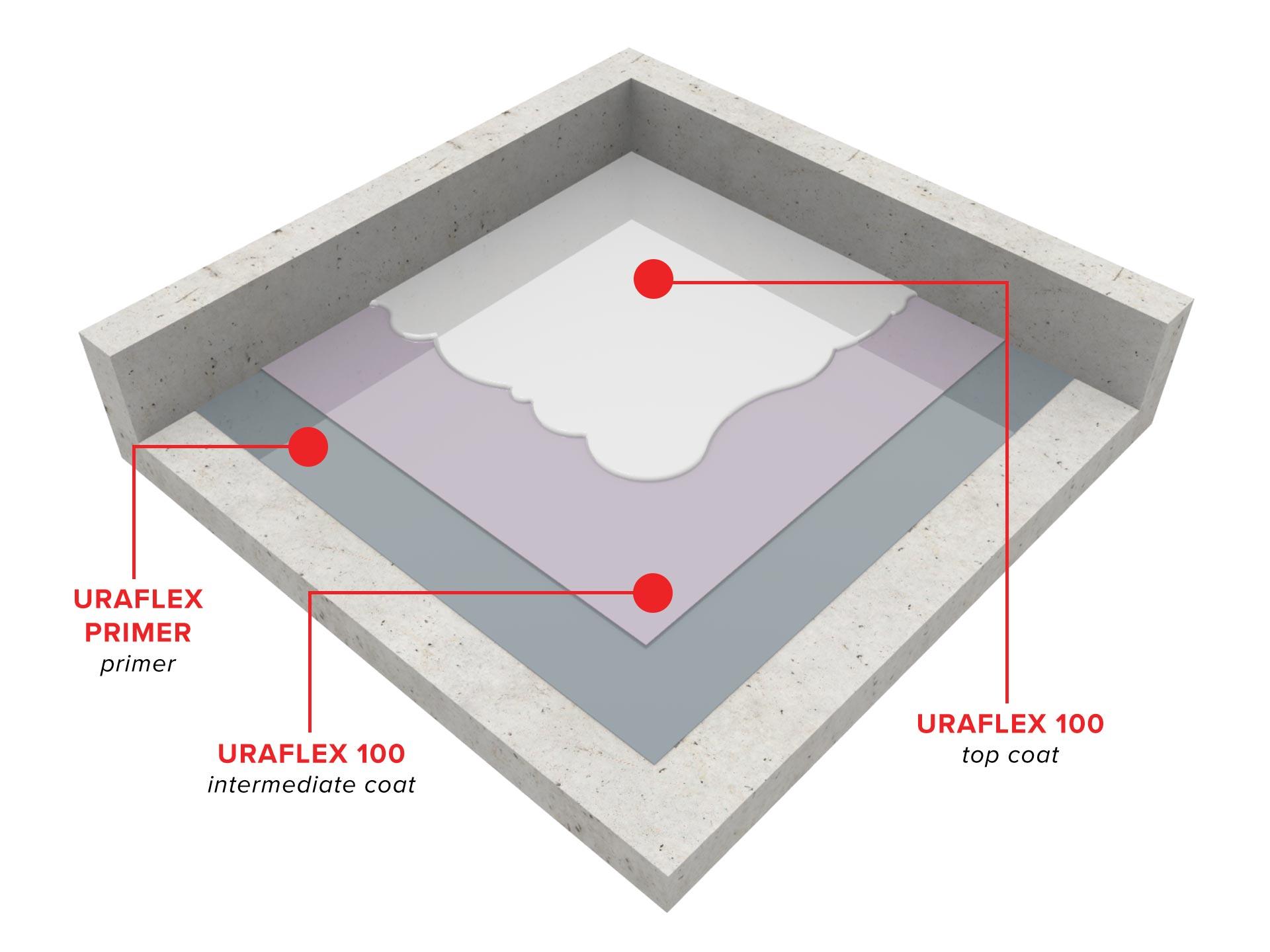

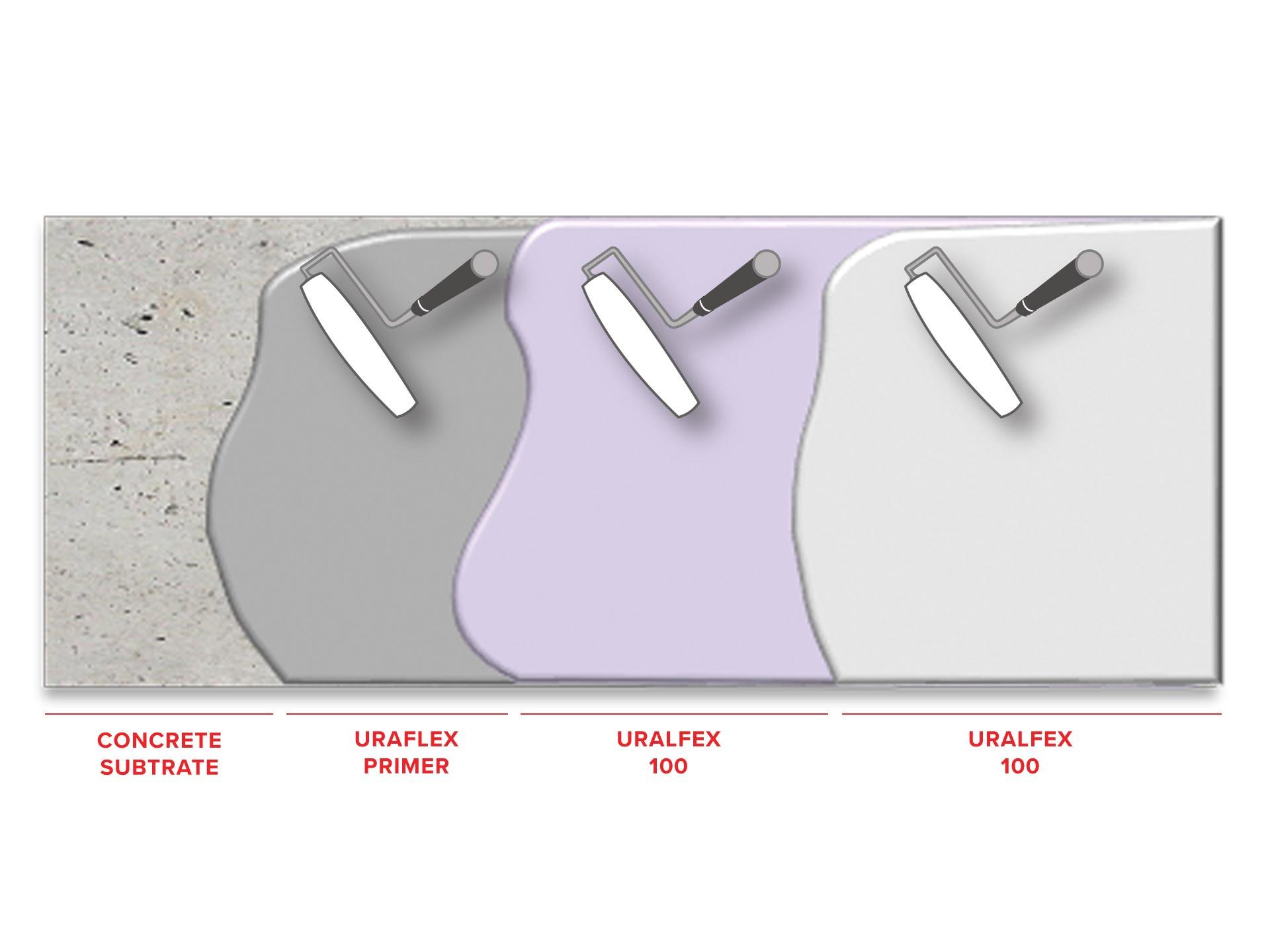

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional Optional Optional Optional |

|

| Intermediate Coat | ||

| Top Coat | ||

| Polyurethane Top Coat | Optional Optional Optional |