Duracrete Trowel System is an extremely durable, single colour, trowel applied industrial floor overlay designed to restore damage concrete or protect new concrete from high impact, abrasion, wear and mild chemicals in institutional, commercial and industrial environments. Duracrete Trowel System consists of a tough silica sand mixture embedded in a highly chemical resistant 100% solids epoxy resin, which is finished to provide an extremely durable, extra heavyduty, highly chemical resistant flooring system.

- Extremely durable, highly abrasion resistant

- Seamless

- 100% solids, VOC free resins

- Proprietary, tightly packed, easy to apply sand mixture

- Can be hand or power troweled

- Moisture insensitive during application and cure

- Will not support growth of fungus or bacteria

- Easy to clean and to maintain

- CFIA approved, USDA accepted

Duracrete Trowel System is used to protect new concrete which will be exposed to mechanical and chemical abuse, or to resurface, level, pitch or slope existing floor slabs in industrial applications. Additional features such as chemical resistance and UV resistance can be attained by applying customizable top coats. Duracrete Trowel System is ideal for extra heavy-duty processing areas, especially for food and beverage industry, high traffic lanes and ailes, heavy-duty production and assembly floors, garbage rooms, wash-down stations, showers and locker rooms and warehouse floors where protection from mechanical abuse is desired and chemical exposure is not severe.

| Colour | Please see Durex® Colour Selection Guide for available colour options. |

|

| Resin Type | Primer: Epotel Multi-Primer Trowel Mortar (Epotel TL + Durex® TL Aggregate) Epotel TL-TL Aggregate Grout Coat: Epotel GSC Topcoat: Epotel GSC |

5 m2/L (200 ft2/gal) @ 8 mils -1 gallon mixed (Part A & B) -66 lbs (30kg) 1.5-2 m2/L (80-120 ft2/gal) @ 15-20 mils WFT -3 m2/L (120-160 ft2/gal) @ 10-15 mils WFT

|

| Ratio | Durex® Epotel TL - 2:1 by volume |

|

| Pot Life @ 23°C | Durex® Epotel TL+ Aggregate - 20 minutes |

|

| Service Temperature Range | Min. 0°C/Max. 50°C/Quick Term 95°C |

| Compressive Strength @ 7 days | ASTM C 579 |

12,000 psi |

|

| Tensile Strength | ASTM C 307 |

1,100 psi |

|

| Flexural Strength | ASTM C 580 |

4,250 psi |

|

| Bond Strength | ACI 503R |

350 psi concrete fails |

|

| Thermal Coefficient of Expansion | ASTM D 696 |

0.00635 mm/inch per 0°C (0.000025 in.) |

|

| Abrasion Resistance - CS-17 wheel, 1 kg. load, 1000 rev. | ASTM D 4060 |

35-45 mg maximum weight loss |

|

| Thermal Shock Resistance | ASTM C 884 |

Passes |

|

| Water Absorption | ASTM C 413 |

0.1% |

|

| Flammability | ASTM D 635 |

Self-extinguishing |

|

| Impact Resistance | MIL D-3134F |

16 ft/lb concrete fractures |

|

| Indentation | MIL D-3134F |

No indentation |

|

| Coefficient of Friction | ANSI A137.1 / ANSI A326.3 |

0.73 WET |

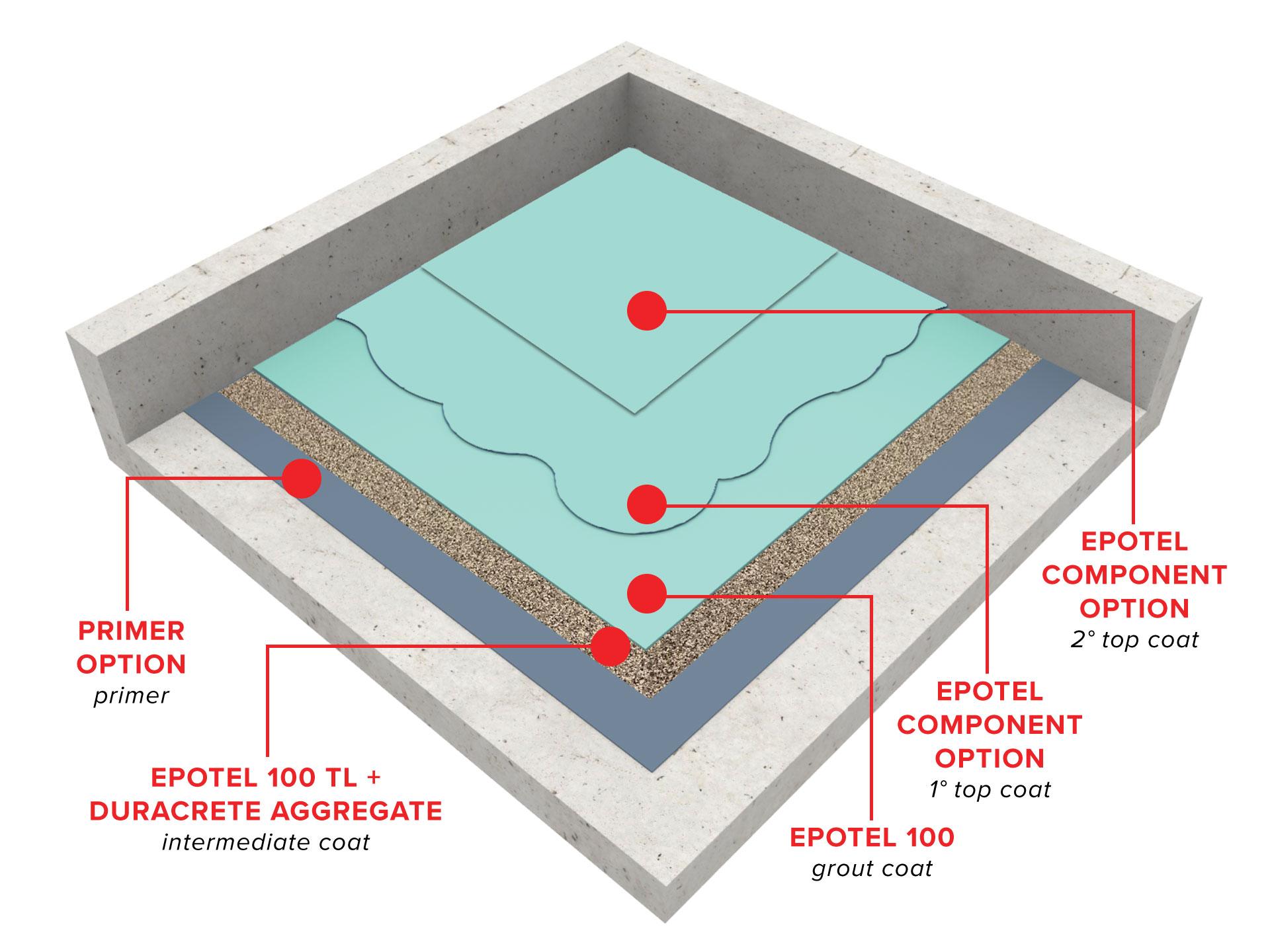

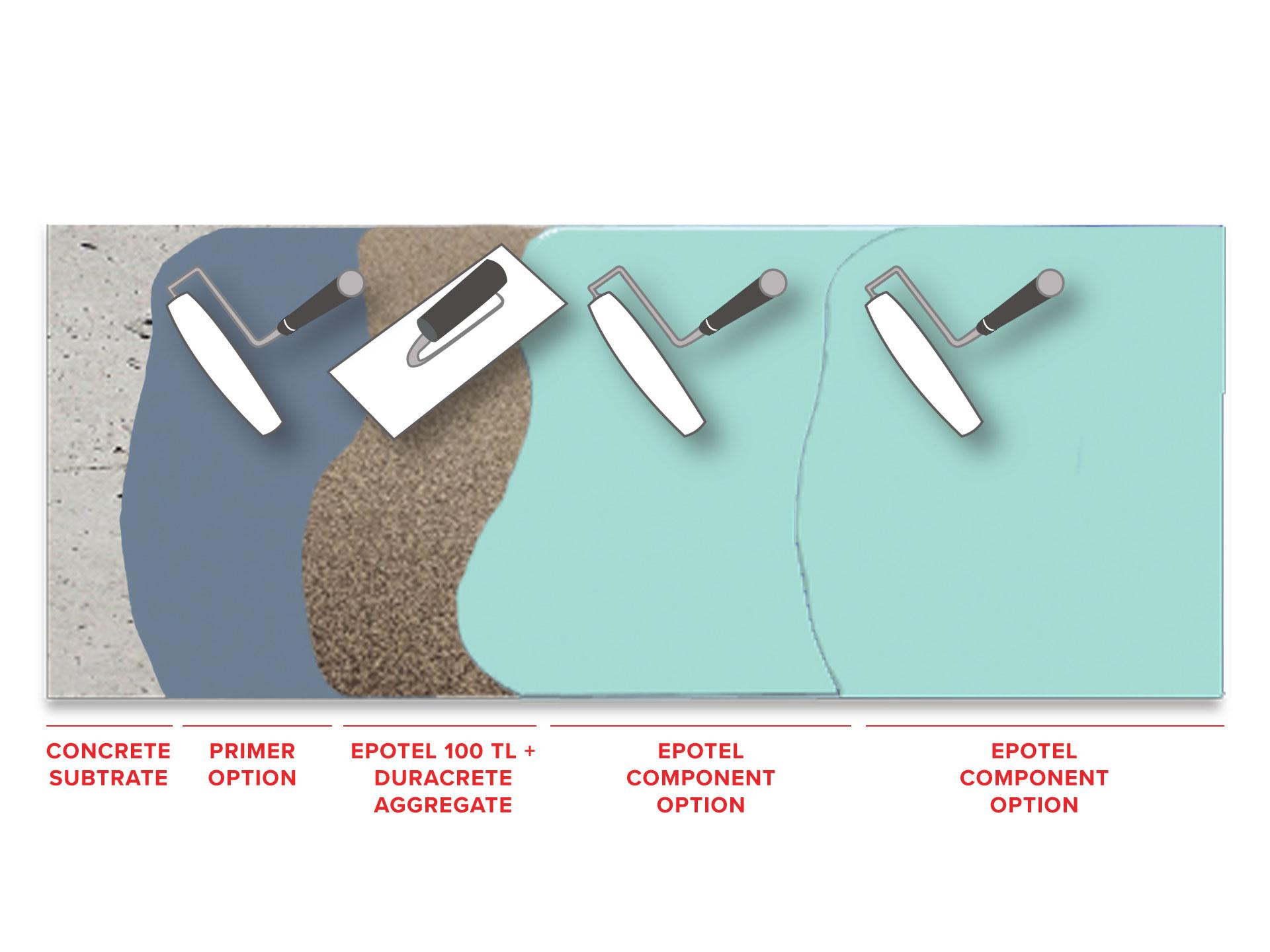

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional Optional |

|

| Intermediate Coat | + Duracrete Trowel Aggregate |

|

| Grout Coat | Optional Optional |

|

| Top Coat | Optional Optional Optional |

|

| Polyurethane Top Coat | Optional Optional Optional |