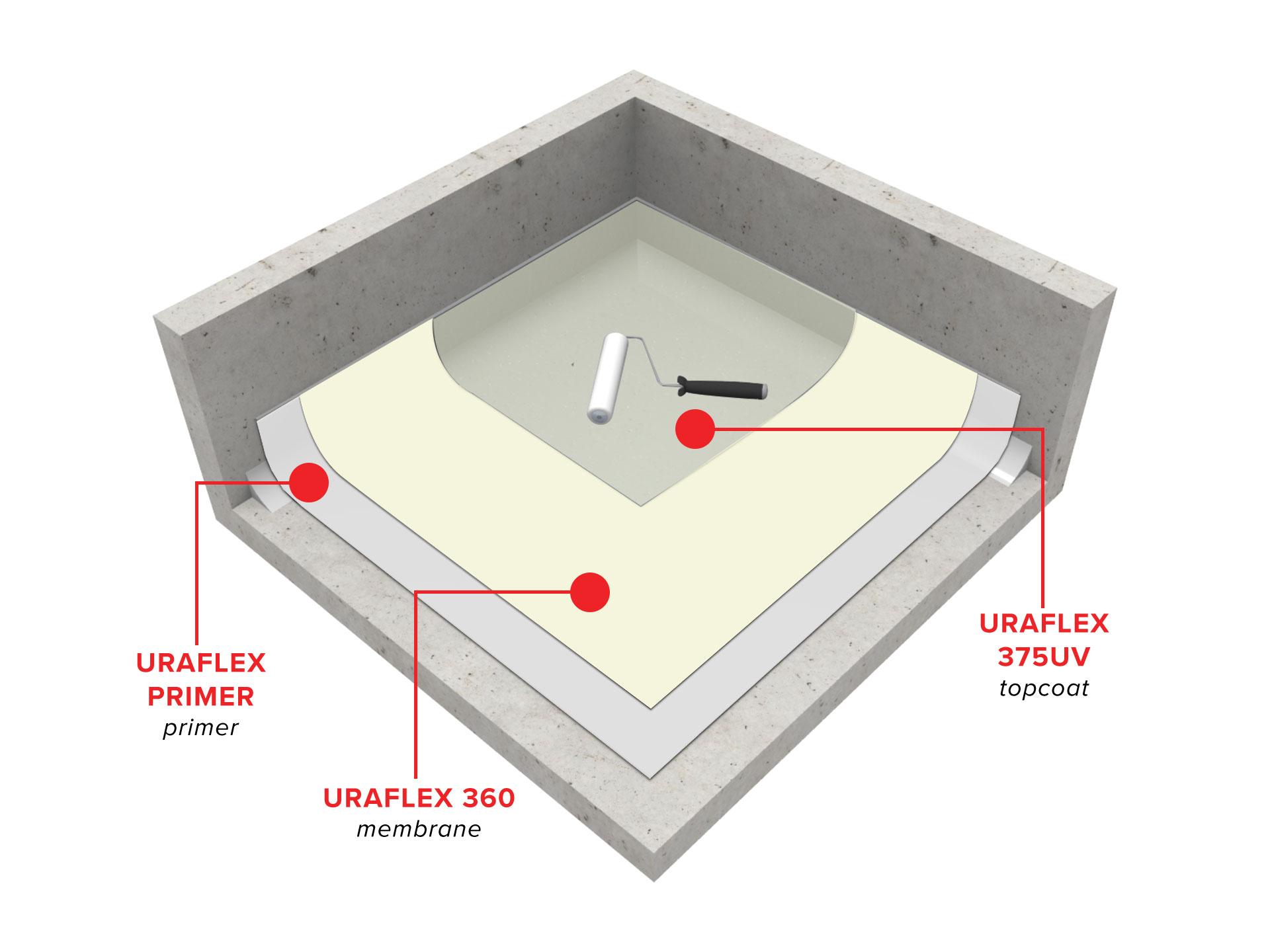

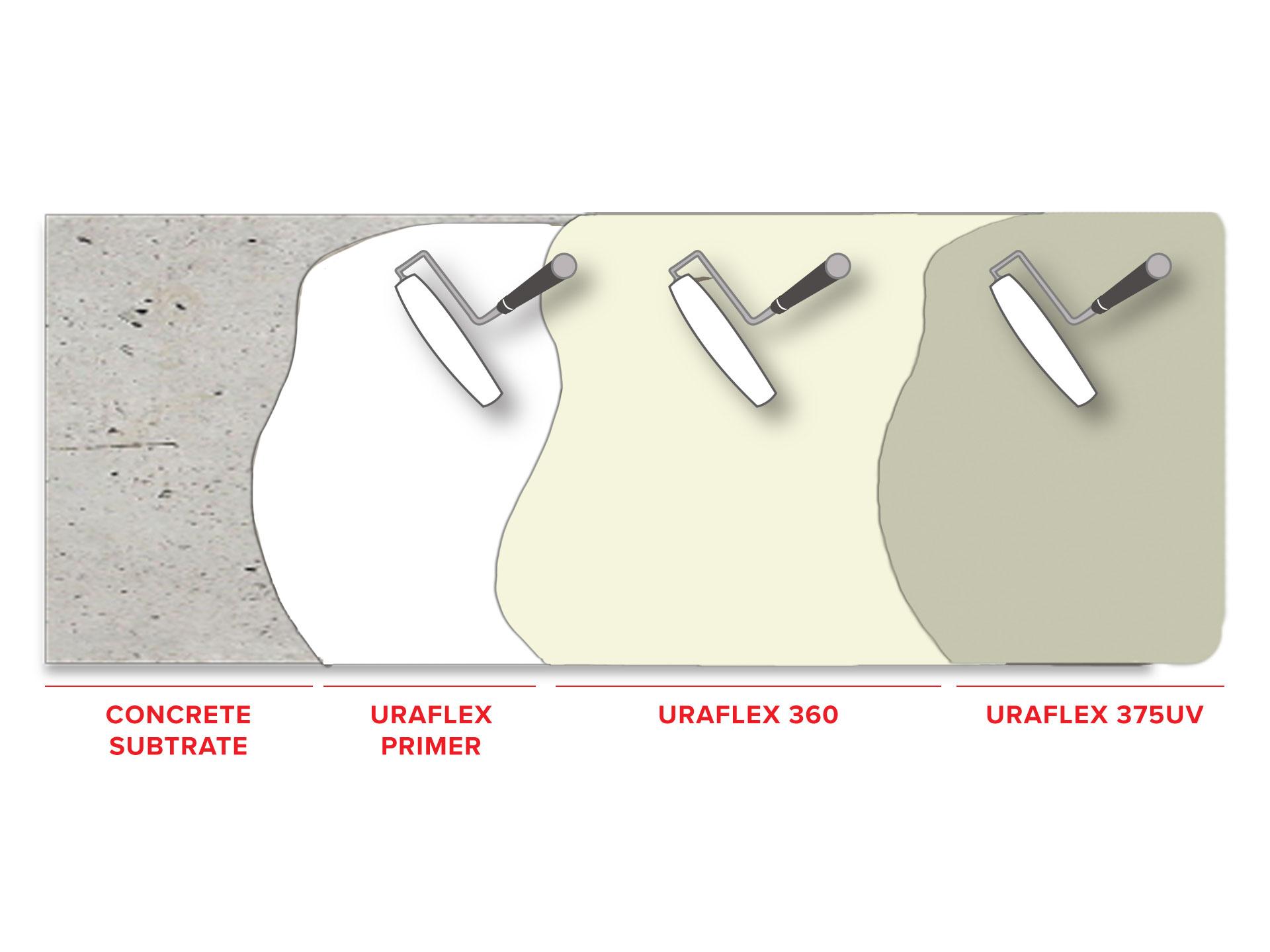

Uraflex 360/375 UV Polyurethane Elastomeric Traffic Bearing Waterproofing System is a solvent free, high-performance deck coating system for balconies and pedestrian traffic subject to UV exposure. The system consists of an elastomeric membrane base coat, Uraflex 360 and an abrasion, UV-resistant topcoat, Uraflex 375 UV. Uraflex 360/375 UV is a UV-resistant, traffic bearing protective waterproofing system which is aesthetically pleasing, resistant to dirt pick-up and is easy to clean

- Abrasion resistant and elastomeric

- Non-skid and decorative

- Waterproof

- Potential LEED Credits

- Solvent free; minimal disturbance to tenants

- UV resistant, durable and long-lasting

- Easy to clean

- Protects from hairline cracks

Uraflex 360/375 UV is intended for use as a protective waterproofing pedestrian deck coating system for concrete, exterior grade plywood, and metal surfaces. It is ideal for balconies, plazas, decks and roof terraces.

| Property | URAFLEX 360NP BASECOAT |

URAFLEX 375 UV TOPCOAT |

| Colour | Light Grey |

Please see Durex® Colour Selection Guide for available colour options. |

| Resin Type | Polyurethane |

Aliphatic Polyurethane |

| Mix Ratio |

|

|

| Coverage | 53 ft2/gal @ 30 mils DFT |

106 ft2/gal @ 15 mils DFT |

| Cure Time @ 35-40°C |

|

|

| Pot Life @ 23°C | 20 minutes |

20 minutes |

| Recommended Film Thickness | 30 mils DFT |

15 mils DFT |

| Recycled Content | 51% |

53% |

| Elongation | ASTM D412 |

900% |

200% |

| Chemical Resistance | ASTM D412 |

Pass |

|

| Pull-Off Strength | ASTM D 4541 |

2.4 MPa (350 psi) over concrete |

4.2 MPa (610 psi) over Uraflex 360 membrane |

| Shore A Hardness | ASTM D 2240 |

67 |

95 |

| Water Vapour Permeability | ASTM E96 |

0.20 perm in. - 0.0025 ng/Pa·s·m2 |

|

| Water Vapour Transmission | ASTM E96-Procedure B |

0.05 g/hr·pi2 - 0.029 g/hr·m2 |

|

| Water Absorption | ASTM D570 |

0.25% |

< 0.5% |

| Low Temperature Flexibility | 1/8” Mandrel @ -26oC |

Pass |

Pass |

| Flexural Modulus | ASTM D522 |

2 mm film passes - 12 mm mandrel |

2 mm film passes - 12 mm mandrel |

| TEST | METHOD |

URAFLEX 360 BASECOAT |

URAFLEX 375 UV TOPCOAT |

| Tear Strength | ASTM D624 |

83 lb/lin.inch |

171 lb/lin.inch (30 KN/ lin. meter) |

| Tensile Strength | ASTM D412 |

2,500 psi |

2,075 psi |

| Abrasion Resistance | ASTM D5178-91-CS-17 wheel |

75 mg loss - 1000 g load, 1000 cycles |

11 mg loss - 1000 g load, 1000 cycles |

| Mixed Viscosity (23°C) | ASTM D2196 |

3300 cps |

1500 cps |

| Specific Gravity | ASTM D333 |

1.19 ± 0.05 g/L |

1.25 ± 0.05 g/L |

| V.O.C | ASTM D3960 |

5 g/L |

0 g/L |

| Percents Solidfs | ASTM D7232 |

99% |

100% |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | ||

| Membrane | ||

| Top Coat |