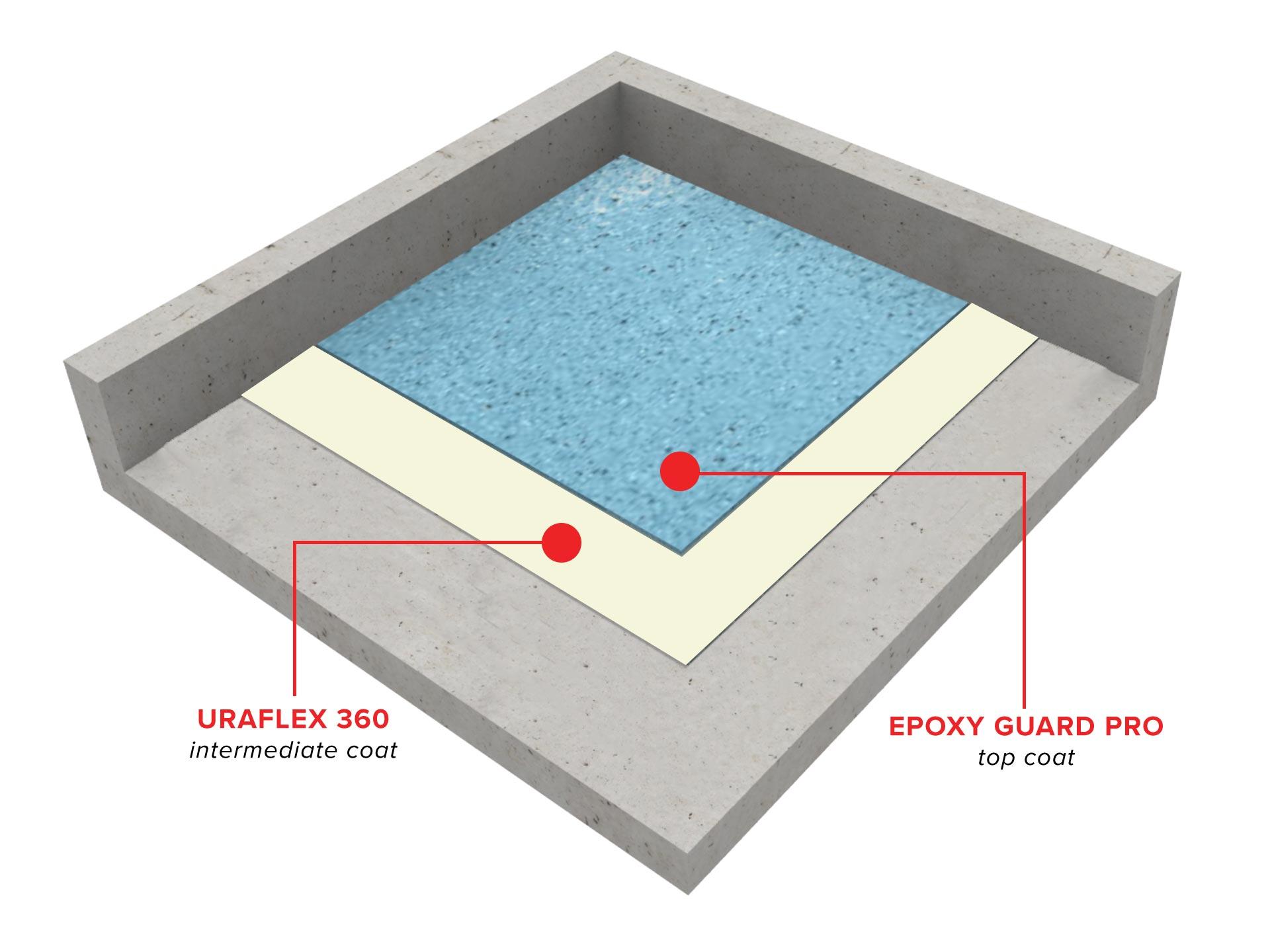

Uraflex Mechanical Room Waterproofing System is a high-performance waterproofing system for mechanical rooms. The system consists of an elastomeric membrane base coat, Uraflex 360 Elastomeric Polyurethane Waterproofing Membrane, and an easy-to-use protective topcoat, Epoxy Guard Pro Professional Use Quick-Drying Water Based Epoxy Coating.

- Abrasion resistant and elastomeric

- Waterproof

- Sound deadening

- Potential LEED credits

- Very low odour, solvent free and minimal disturbance to tenants

- Durable, long-lasting and easy to clean

- Protects from hairline cracks

Uraflex Mechanical Room Waterproofing System is intended for use as a protective mechanical room waterproofing system. It is used for suspended slab mechanical rooms with no floors below and is ideal for mechanical rooms, sensitive equipment and server rooms.

| PROPERTIES | URAFLEX 360 BASECOAT |

EPOXY GUARD PRO TOPCOAT |

| Colour | Beige |

Please see Durex® Colour Selection Guide for available colour options. |

| Resin Type | Polyurethane/Hybrid polyol |

Water-based epoxy |

| Mix Ratio |

|

|

| Coverage | 1.2 m2/L (50 ft2/gal) @ 30 mils |

7 m2/L (400 ft2/gal) @ 2 mils/coat; 2 coats |

| Cure Time @ 35-40°C |

|

|

| Pot Life @ 23°C | 20 minutes |

3 hours |

| Recommended Film Thickness | 20 mils DFT |

20 mils DFT |

| pH Level | 7-8 |

| TEST | METHOD |

URAFLEX 360 BASECOAT |

EPOXY GUARD PRO TOPCOAT |

| Percent Solids | ASTM D7232 |

100% |

50 ± 2% (vol.) clear |

| V.O.C. | ASTM D3960 |

0 g/L |

< 30 g/L |

| Specific Gravity | ASTM D333 |

1.20 ± 0.05 g/L |

|

| Viscosity (Brookfield 23°C) | ASTM D2196 |

2,500 cps |

|

| Abrasion Resistance |

|

|

|

| Tensile Strength | ASTM D412 |

1,350 psi |

|

| Tear Strength | ASTM D624 |

||

| Elongation | ASTM D412 |

900% |

|

| Flexural Modulus | ASTM D522 |

|

|

| Low Temperature Flexibility | 1/8 in. mandrel @ -26°C |

||

| Water Absorption | ASTM D570 |

< 0.5% |

|

| Water Vapour Transmission | ASTM E96- Procedure B |

|

|

| Water Vapour Permeability | ASTM E96 |

|

|

| Water Vapour Permeance | ASTM E96 |

|

|

| Shore D Hardness | ASTM D2240 |

71 |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional |

|

| Membrane | ||

| Top Coat |