Durex® Komfort ERGO is a seamless, 4mm thick polyurethane-based ergonomic, sound-deadening comfort floor system that features a 2mm shock-absorbing membrane for user comfort and sound absorption. Durex® Komfort ERGO is designed and engineered for dry areas such as laboratories, corridor areas, and a variety of institutional and healthcare settings. Easy to overcoat and repair. Easy to overcoat and repair. Available in solid colour (standard finish) or multi-effect finishes (DecoArt).

- Ergonomic and soft 2mm membrane; noise reduction

- Available in a multitude of decorative finishes

- High performance, aesthetically pleasing, durable finish

- Easy and quick to install

- Long-term service life

- Easy to recoat and repair

- Thin, lightweight seamless flooring system, easily upturned to create curbs and containment areas

- Will not support the growth of fungus or bacteria

- Excellent abrasion and slip resistance

- Easy to clean and maintain

- CFIA approved and USDA accepted

Durex® Komfort ERGO System is used as a decorative and protective ergonomic flooring system for dry areas that will be exposed to higher traffic where sound absorption and user comfort are desired. It is best used for health care, institutional, and office flooring applications where a seamless flooring system with sound-deadening properties is required.

• Laboratories

• Hospital Main Corridors (dry areas)

• Retail and Commercial Applications

• Hallways

• Recreational facilities

• Public institutions and buildings

• Offices

| Colour | Standard Finish: Solid Colour. |

|

| Mix Ratio | Refer to Product TDS Sheet |

|

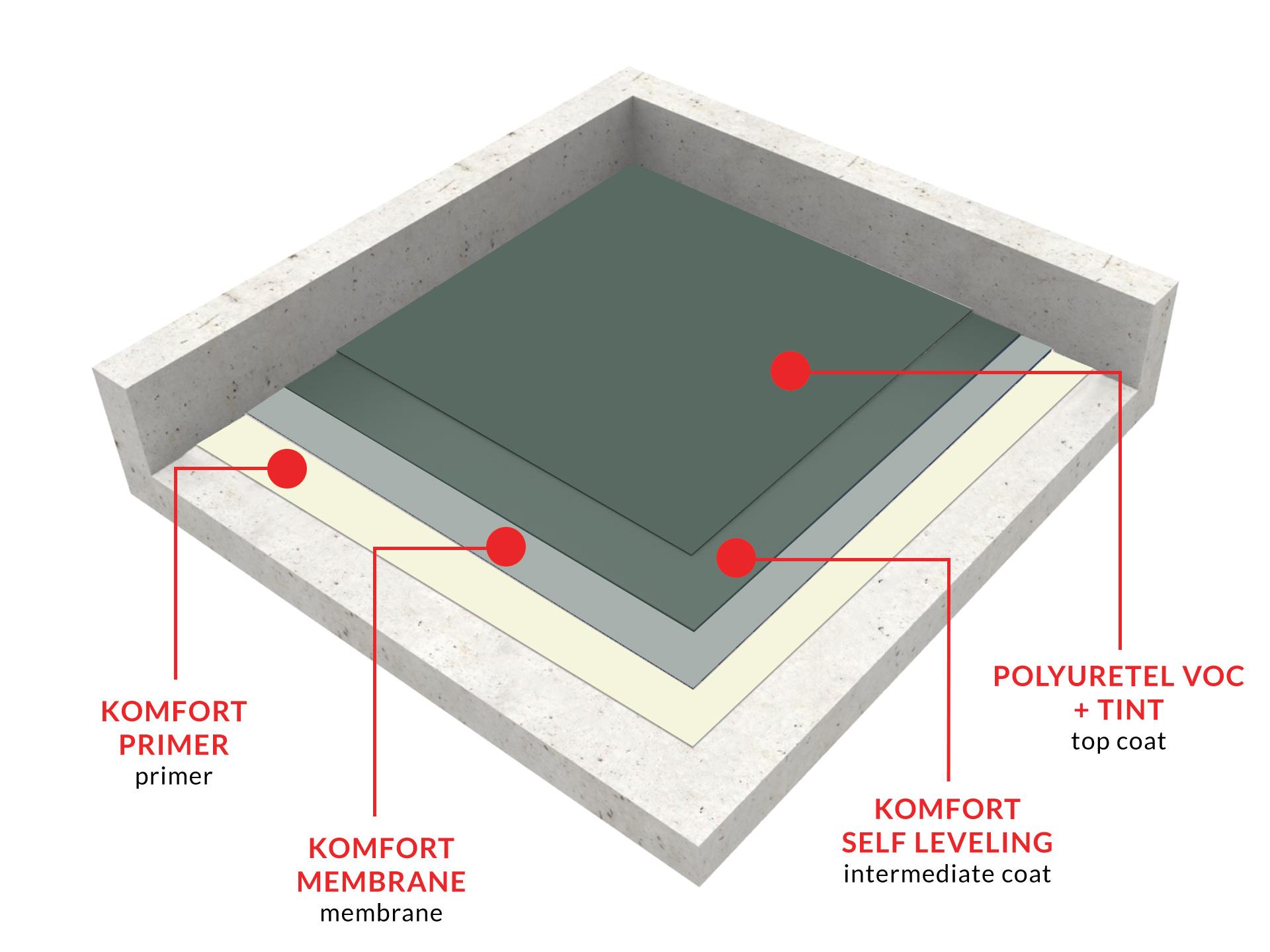

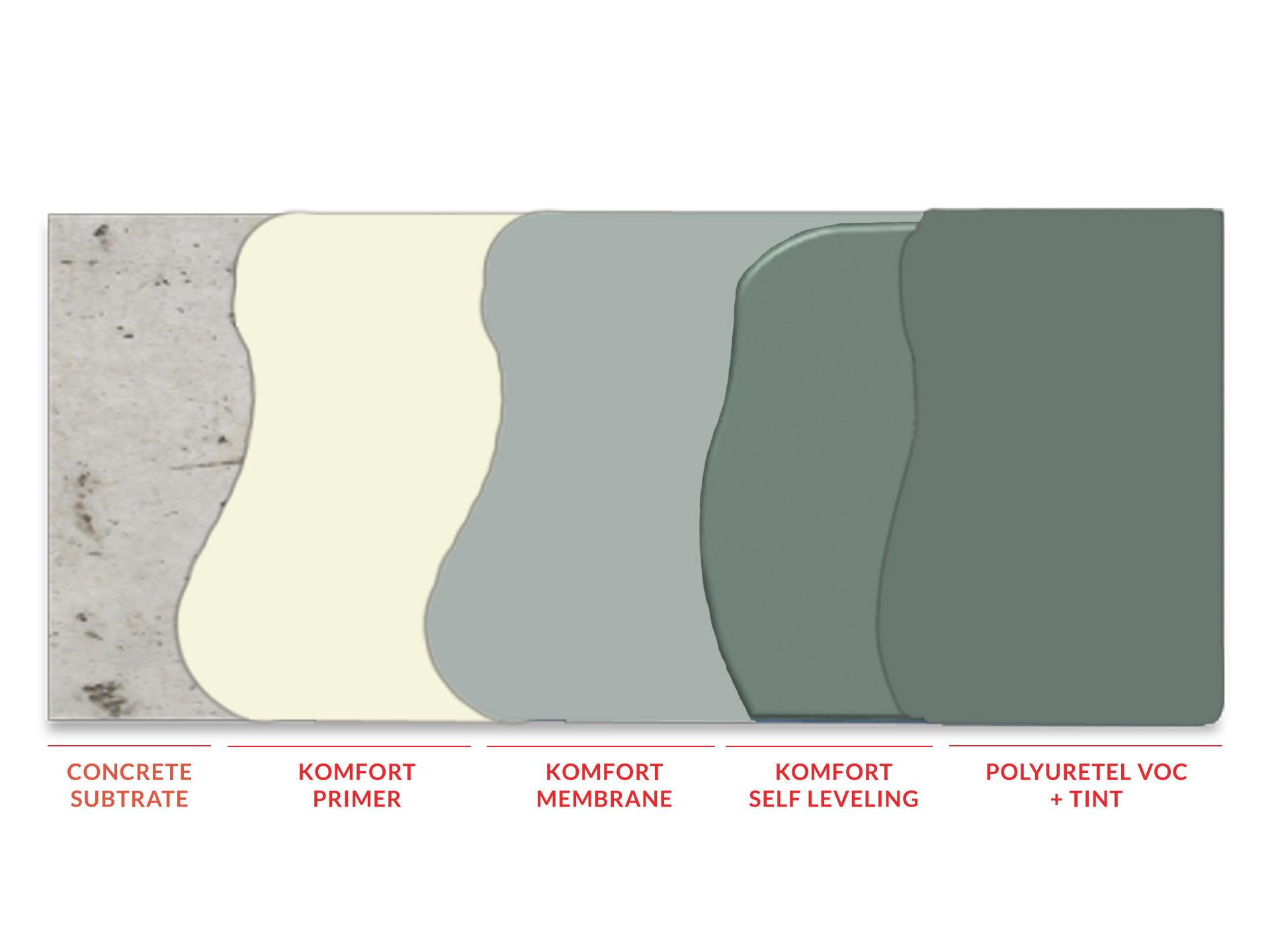

| Coverage | Durex® Komfort Primer Durex® Komfort Membrane Durex® Komfort Self-Leveling

Durex® Komfort Top Coat |

5 m2/L (200 ft2/gal) @ 8 mils 2.0kg/m2 (95 ft2/20 kg kit) @ 2mm (80 mils) Durex® Komfort Self Leveling (or Durex® Komfort DecoArt: 3.0kg/m2 (70 ft2/20 kg kit) @ 2mm (80 mils) 0.1 kg/m2 (400 ft2/gal) @ 3 mils WFT (2 coats) |

| Pot Life | Refer to Product TDS Sheet |

|

| Service Temperature Range | Minimum: -20C/Maximum: 50C/Quick Term: 95C |

| Percent Solids | ASTM D7232-06 |

100% |

|

| Shore Hardness A | ASTM D2240 |

83 |

|

| Sound Dampening | <12 db |

||

| Suitable for Underfloor Hearting | Yes |

||

| Abrasion Resistance | ASTM D4060 |

(-0.03g) C5-17/ 1000 rotations/1000g |

|

| Impact Strength | ASTM D4226 |

167 in./ lbs. |

|

| Residual Impression | ASTM D4226 |

0.05mm (360kg load) |

|

| Tensile Strength | ASTM F970 |

1,454 psi. (~ 10.0 N/mm²) |

|

| Tensile Adhesion Strength | ASTM 4541 |

> 500 psi. (3.5 MPa) (concrete failure) |

|

| Tear Strength | ASTM D624 |

153.36 lb./in. (~27 N/mm 14 days) |

|

| Elongation at Break | ASTM D412 |

195% |

|

| Crack Bridging Ability | ASTM C1305 |

Passed |

|

| External Fire Performance | ASTM E648 |

Class I |

|

| Gloss Level | ASTM D-523 |

10 (60 Degrees) |

|

| Coefficient of Friction | ANSI 326.3 |

0.6 |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | ||

| Membrane | ||

| Intermediate Coat | ||

| Top Coat |