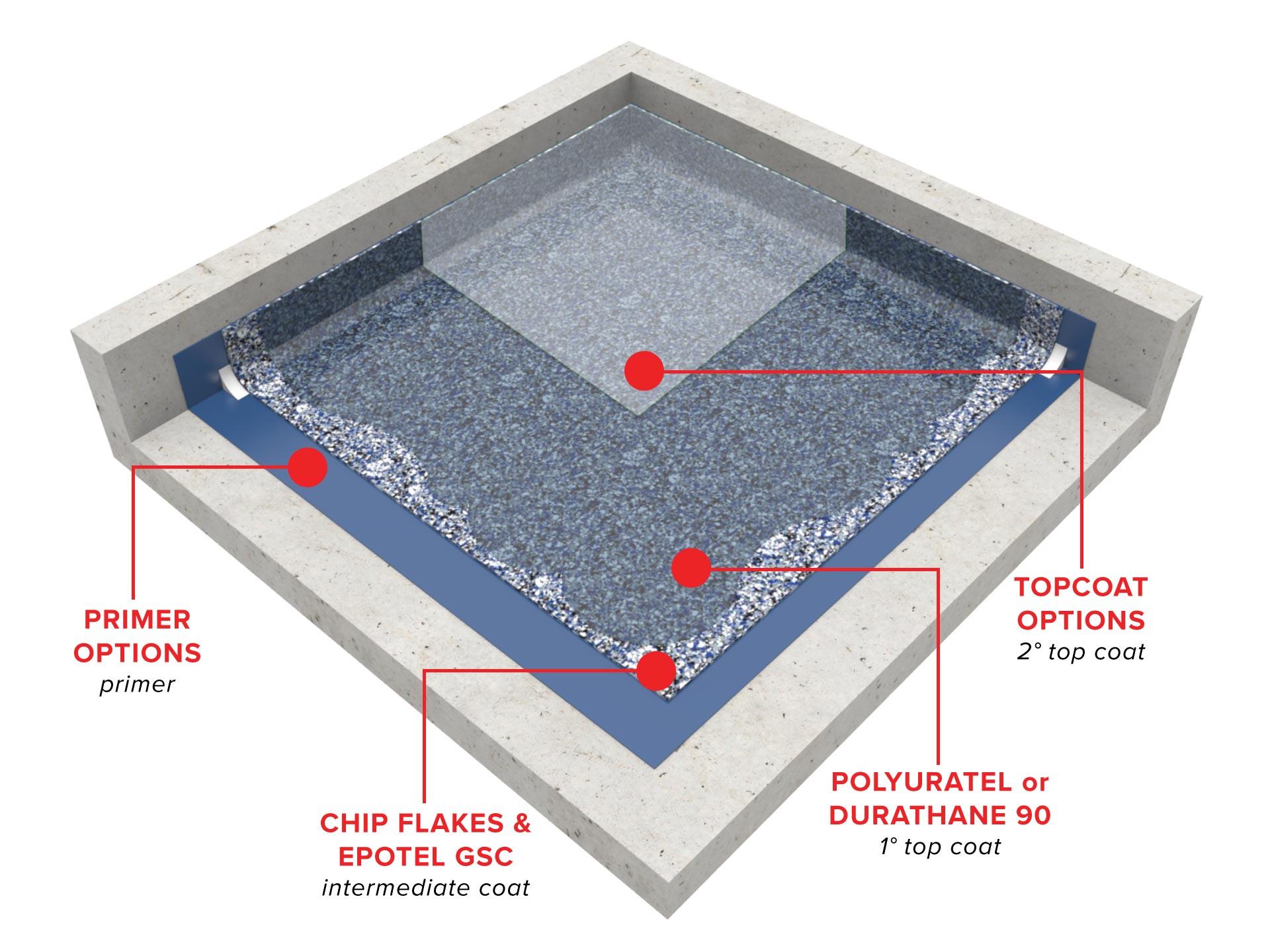

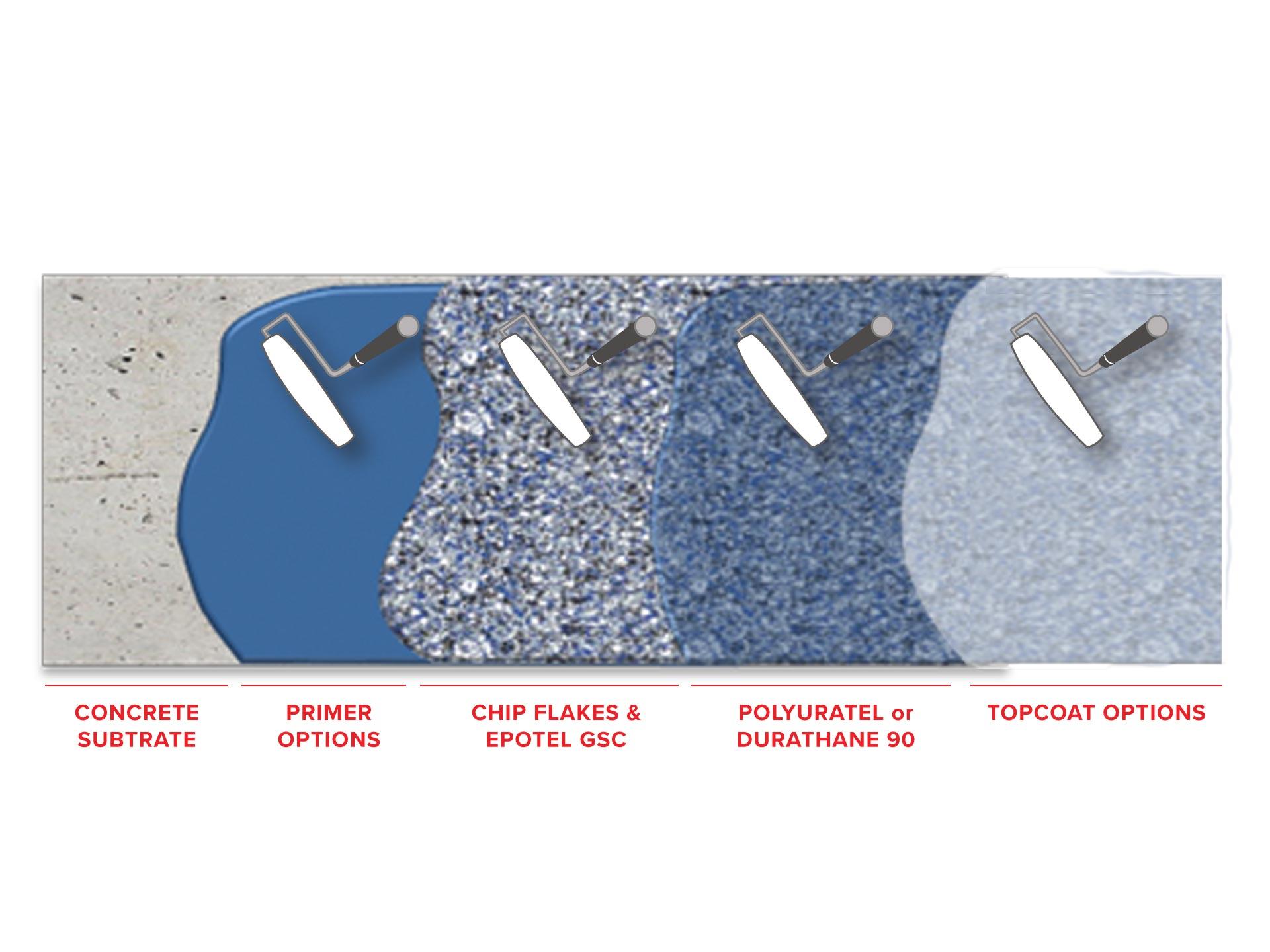

Dur-A-Flake Chip Flake Floor System is a decorative multi-coloured chip flake, seamless epoxy floor system. It is easily installed as a system to produce a tough durable multi-coloured granite-like finish. Dur-A-Flake incorporates a coloured epoxy-based primer, a body coat with multi-coloured paint chip flakes, a clear grout coat and a clear abrasion resistant topcoat sealer to yield a long wearing decorative floor. Installed at 50 mils (1.5 mm), the Dur-A-Flake offers excellent performance for a variety of floor areas.

- Fast and easy installation for a decorative appearance

- Very low odour

- Economical and durable floor with excellent colour retention properties

- Resistant to contaminants such as salt and light chemicals

- CFIA accepted

- Will not support growth of fungus or bacteria

- Customizable finishing sheen

- Impermeable and waterproof

- 8 standard colour blends

- Customizable colours and blends available

Dur-A-Flake Chip Flake Floor System is used as a decorative flooring system to product a long-term, low maintenance floor for high traffic retail, commercial, residential and institutional applications. The finish topcoat is available in smooth or fine texture to provide sure footing and anti-slip properties. Dur-A-Flake Chip Flake Floor System is ideal for decorative flooring applications subject to high traffic, variety of commercial and retail applications, institutional floors, health care facilities, laboratories and residential applications, especially residential garages.

| Colour | Please see Durex® Dur-A-Quartz Colour Selector for available colour options. |

|

| Coverage | Primer: (Durex® Epotel GSC) Decorative Flake Broadcast: (Durex® Epotel GSC + Durex® Decorative Chip Flakes)

Grout Coat:(Durex® Epotel 1000) Top Coat (Optional) : (Durex® Polyuretel) (Durex® Durathane 90) (Durex® Acrutel 100) |

5 m2/L (200 ft2/gal) @ 8 mils WFT -Epotel GSC: 2.5 m2/L (100 ft2/gal) @ 15 mils -Decorative Flakes: Full saturation to excess broadcast. Approx. 1 m2/kg (5 ft2/ lb)

4 m2/L (160 ft2/gal) @ 10 mils

For design coverage check specific products technical data sheet

|

| Mix Ratio | 2:1 by volume |

|

| Pot Life | 25 minutes (Epotel GSC) |

|

| Service Temperature Range | Minimum: 0°C/Maximum: 50°C/Quick Term: 95°C |

| Compressive Strength @ 7 days | ASTM C 579 |

11,500 psi |

|

| Tensile Strength | ASTM C 307 |

3,000 psi |

|

| Flexural Strength | ASTM C 580 |

10,500 psi |

|

| Bond Strength | ACI 503R |

350 psi concrete fails |

|

| Abrasion Resistance - CS-17 wheel, 1 kg. load, 1000 rev. | ASTM D 4060 |

35-45 mg. max weight loss |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional Optional Optional Optional Optional |

|

| Intermediate Coat | + Coloured Chip Flakes |

|

| Polyurethane Top Coat | Optional Optional |

|

| Epoxy Top Coat | Optional |