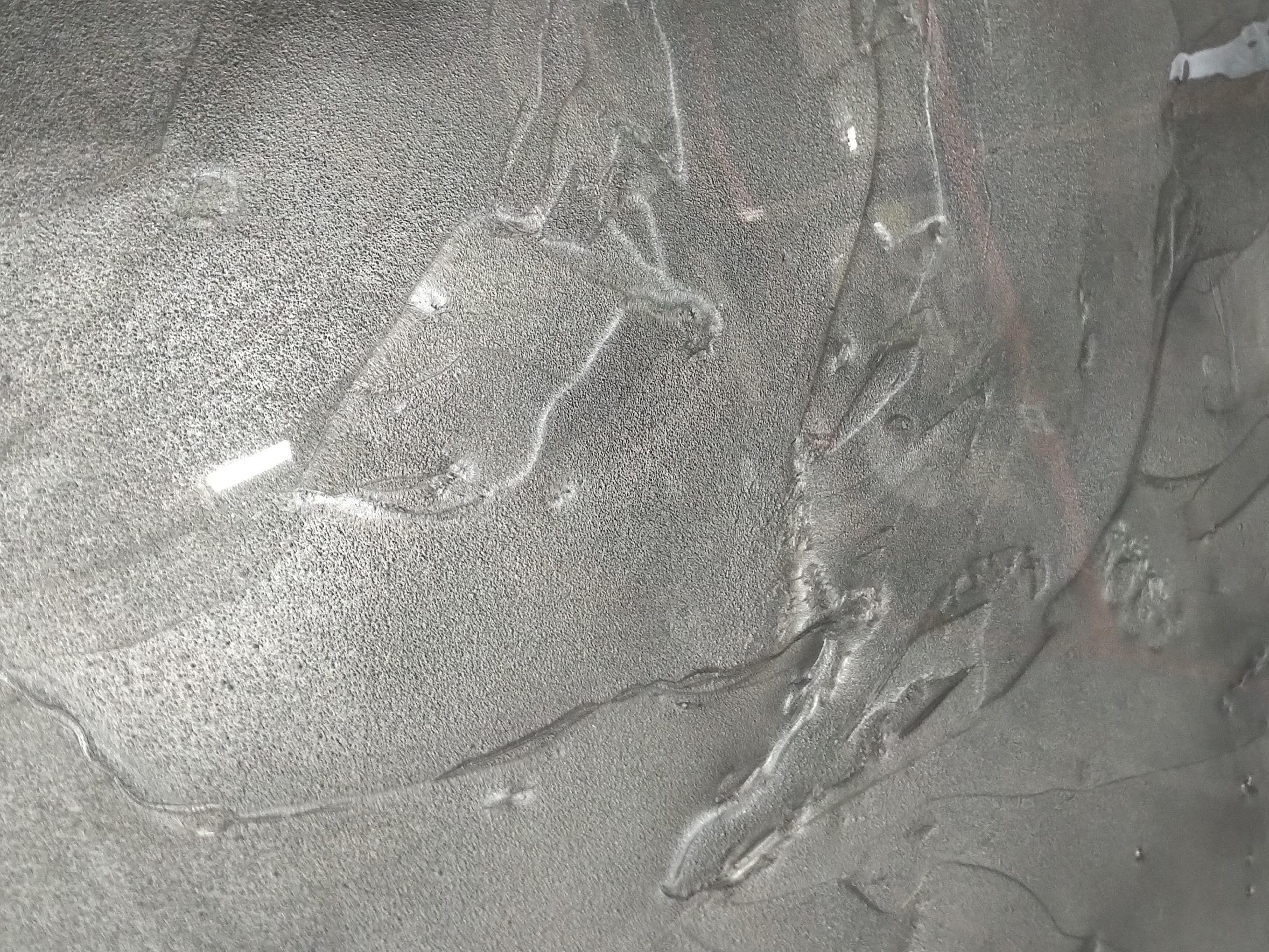

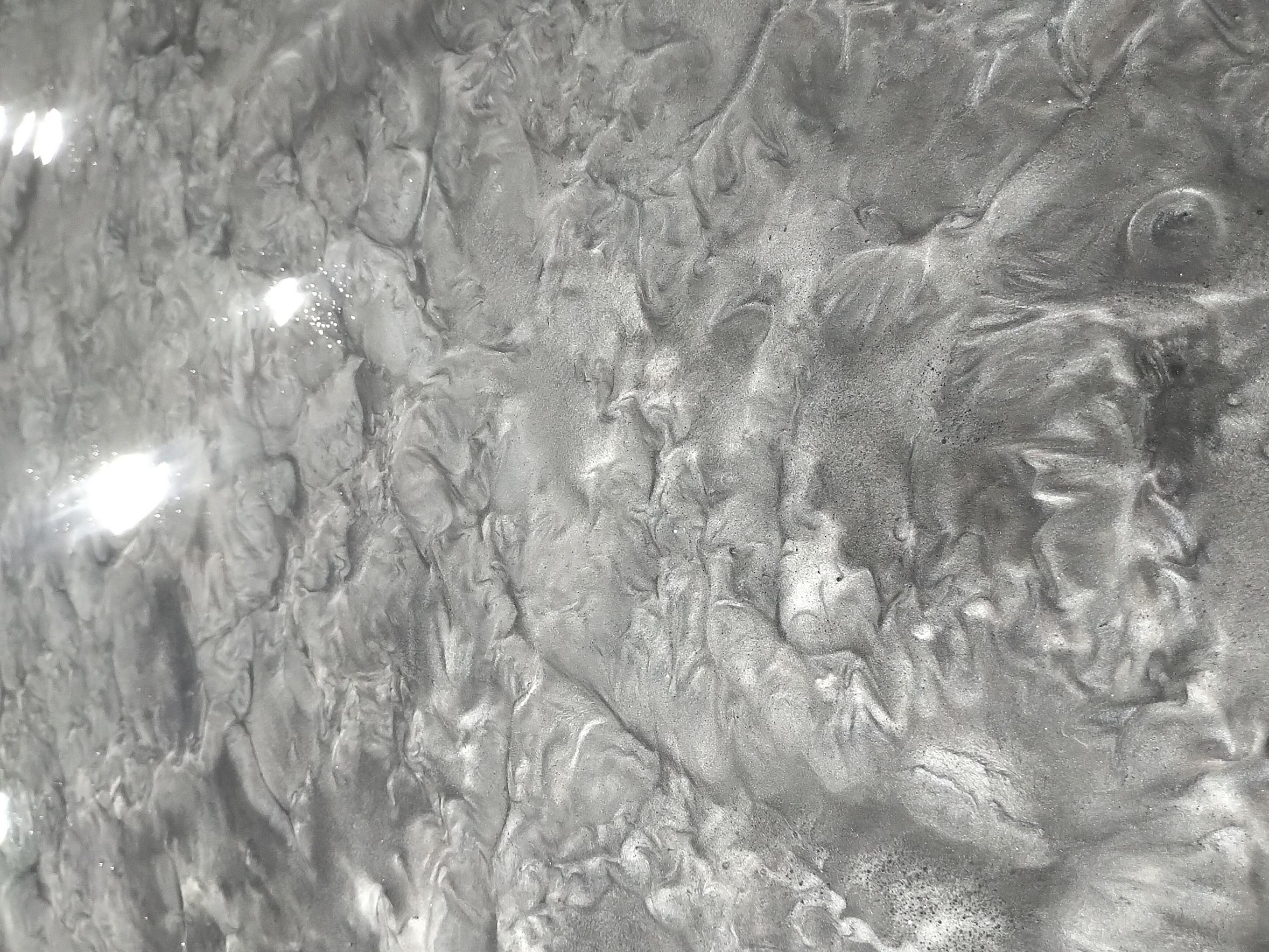

Durex® Dur-A-Metallic is a durable, pearlescent metallic, seamless resinous flooring system. This architectural flooring system creates a three-dimensional, striking and vivid appearance with a seamless epoxy-based chemistry for a floor with exceptional durability and long-lasting performance. Applied at a thickness of 2-3mm for enhanced visual effect.

- High build (2-3mm) for enhanced multi-dimensional aesthetics

- Highly reflective and vivid finish

- 100% solids, VOC-free resins

- Wide variety of colour and design combinations

- Customizable designs available

- Seamless. Will not support the growth of fungus or bacteria

- Easy to clean and maintain

- CFIA approved, USDA accepted

Durex® Dur-A-Metallic is formulated to be applied over concrete substrates to achieve a uniquely architectural, pearlescent metallic floor. To be used as a resinous flooring system for a variety of commercial, institutional, retail and residential applications. Can be integrated with a cove for a seamless, contained flooring system.

• Retail Stores and Commercial Areas

• Institutional Facilities

• Showrooms and feature floor areas

• Healthcare and educational facilities

| Colour | Please see Durex® Colour Selection Guide for available colour options. |

|

| Mix Ratio | As Supplied. Refer to TDS Sheet |

|

| Pot Life @ 23°C | Refer to TDS Sheet |

|

| Service Temperature Range | Min. 0°C/Max. 50°C/Quick Term 95°C |

| Compressive Strength @ 7 days | ASTM C 579 |

12,500 psi |

|

| Tensile Strength | ASTM C 307 |

3,200 psi |

|

| Flexural Strength | ASTM C 580 |

6,000 psi |

|

| Bond Strength | ACI 503R |

350 psi concrete fails |

|

| Thermal Coefficient of Expansion | ASTM D 696 |

0.00635 mm/inch per 0°C (0.000025 in |

|

| Abrasion Resistance | ASTM D 4060 CS-17-wheel, 1 kg. load, 1000 rev. |

25 mg maximum weight loss |

|

| Thermal Shock Resistance | ASTM C 884 |

Passes |

|

| Water Absorption | ASTM C 413 |

Less than 0.1% |

|

| Impact Resistance | MIL D-3134F |

16 ft/lb concrete fractures (Pass) |

|

| Indentation | MIL D-3134F |

0.02 (No discernable indentation) |

|

| Flammability | ASTM D-635 |

Self-Extinguishing |

|

| Shore Hardness (D) | ASTM D-2240 |

90 |

|

| Coefficient of Friction | ANSI A137.1 / ANSI A326.3 |

0.58 wet to 0.90 dry (with Durex® Shark Grip) |

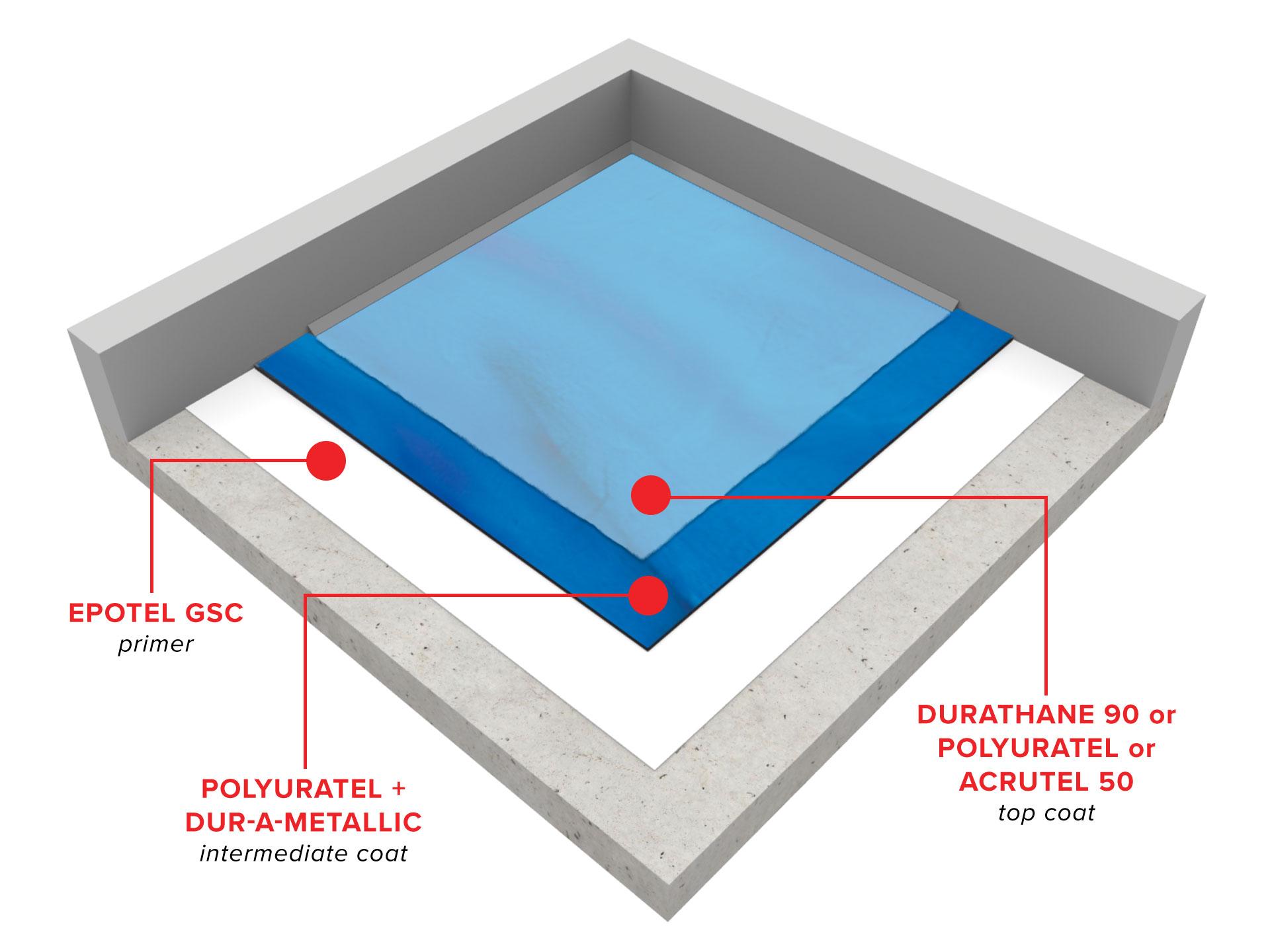

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Primer | Optional Optional Optional |

|

| Base Coat | ||

| Intermediate Coat | + Dur-A-Metallic Pigment |

|

| Polyurethane Top Coat | Optional Optional |