89/ft² (8.27/m²) per Gallon @ 18.00 mils (0.4572 mm)

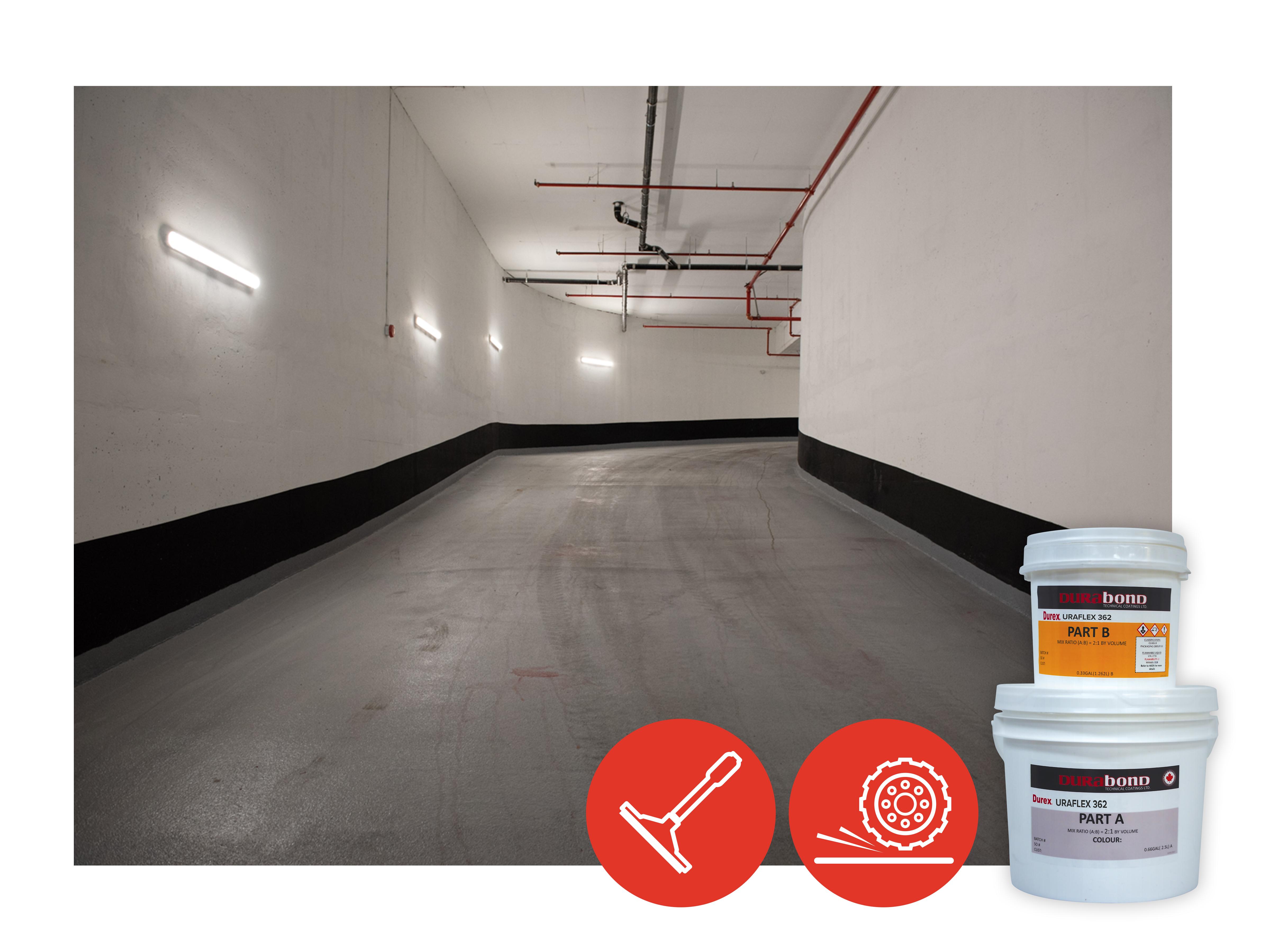

Uraflex 362 Elastomeric Polyurethane Traffic-Bearing Topcoat is a two-component, solvent-free, high solids elastomeric polyurethane topcoat specially formulated for high-level traffic-bearing surfaces. It is designed to adhere to Uraflex 360 Elastomeric Polyurethane Waterproofing Membrane and Uraflex 361 Traffic-Bearing Topcoat and other similar traffic-bearing coatings to form a highly effective traffic-bearing waterproofing system

- Resilient coating with high abrasion resistance

- Outstanding water-impermeability sealing properties

- Very low odour and zero VOCs

- Potential LEED credits

- Excellent water immersion properties

- Self-cleaning, fast curing, and easy to apply and to maintain

- Superior abrasian and scratch resistance, high tensile strength

Uraflex 362 Elastomeric Polyurethane Traffic-Bearing Topcoat is used as a resilient high-abrasion topcoat for traffic-bearing waterproofing systems in high demand areas such as turning lanes, ramps and booth entrance areas. It can be recoated for additional wear resistance. Anti-slip performance is achieved by broadcasting silica sand or aluminum oxide grit into the coating. Uraflex 362 is also used for parking decks, high traffic areas- ramps, turning lanes, booth-collection areas, mechanical rooms with extreme traffic, plaza, pools and recreational decks, vehicular ramps and stadiums.

| Colour | Please see Durex® Colour Selection Guide for available colour options | |

| Mix Ratio |

| |

| Cure Time @ 35-40°C |

| |

| Pot Life @ 23°C | 25 minutes | |

| Coverage | 89 ft²/gal @ 18 mils DFT | |

| Recommended Film Thickness | 15-25 mils DFT | |

| Recycled Content | 53% |

| Method | Results | |

|---|---|---|

| Percent Solids | ASTM D7232 | 100% |

| Percent Solids | ASTM D7232 | 100% |

| V.O.C. | ASTM D3960 | 0 g/L |

| Specific Gravity | ASTM D333 | 1.25 ± 0.05 g/L |

| Viscosity | ASTM D2196 | 2500 cps |

| Abrasion Resistance | ASTM D5178-91, CS-17 wheel | 11 mg loss, 1000 g load, 1000 cycles |

| Tensile Strength | ASTM D412 | 2,800 psi |

| Tear Strength | ASTM D624 | 171 lb-lin.inch (30 KN/ lin. metre) |

| Elongation | ASTM D412 | 30% |

| Flexural Modulus | ASTM D522 | 2 mm film passes 12 mm mandrel |

| Low Temperature Flexibility | 1/8" Mandrel @ -26oC | Pass |

| Water Absorption | ASTM D570 | < 0.5% |

| Water Vapour Transmission | ASTM E96 | 0.29 metric perm |

| Shore Hardness | D | 75 |

| Chemical Resistance | ASTM D543 |

|