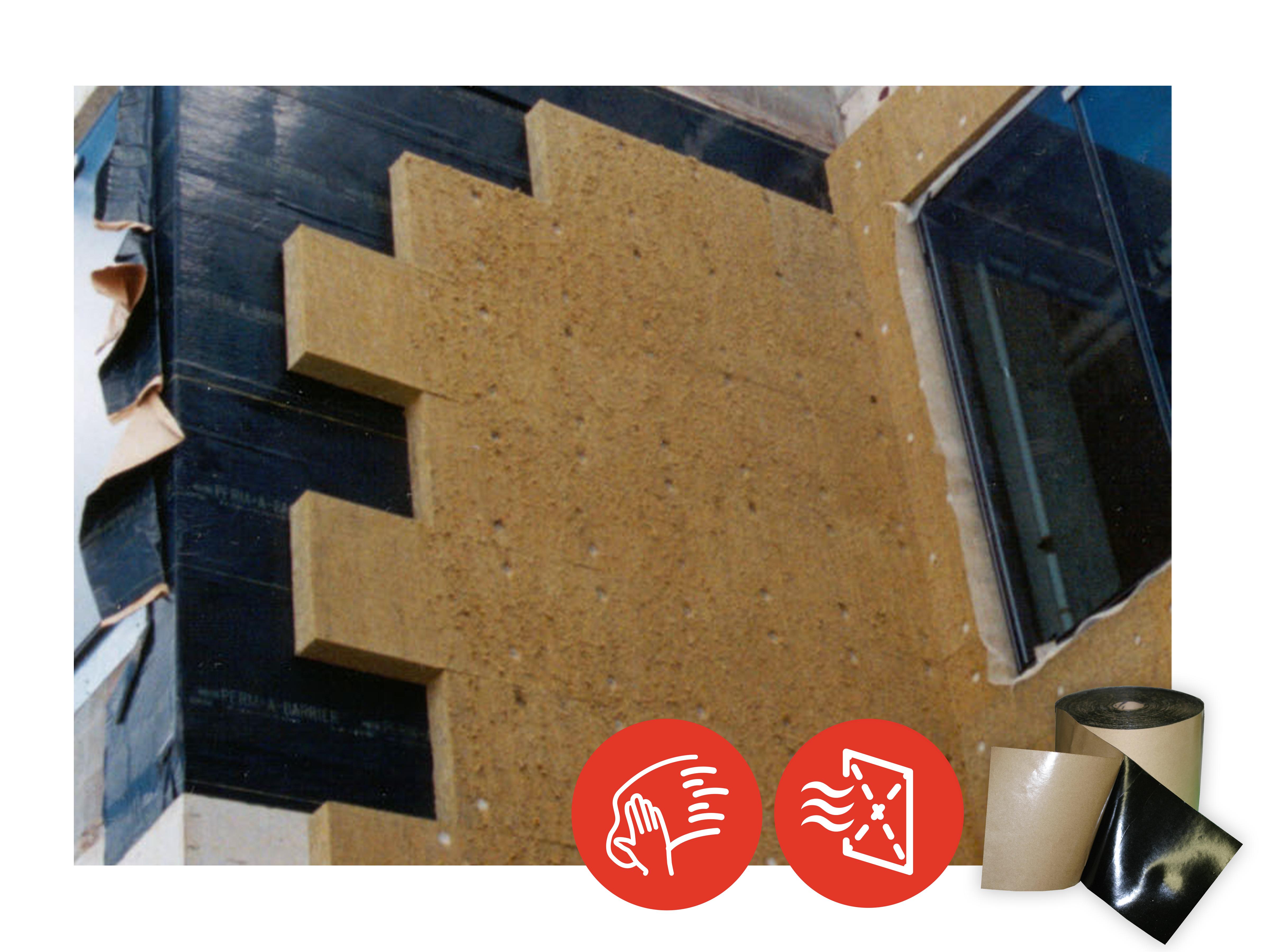

FlexSeal Membrane Air/Vapour Barrier is a self-adhering, cold applied composite sheet membrane comprised of 0.9 mm (36 mils) of rubberized asphalt integrally bonded to a 0.1 mm (4 mils) film of high density, cross laminated polyethylene for a minimum thickness of 1.0 mm (40 mils). For ease of application FlexSeal Membrane Air/Vapour Barrier is inter-wound with a disposable silicone treated release paper. FlexSeal Membrane Air/Vapour Barrier is dark grey to black in colour.

- Excellent adhesion to various substrates.

- Ideal for sprayed polyurethane foam insulation.

- Self-sealing membrane ensuring continuous waterproofing.

- Available in 36", 18", and 6" roll widths.

FlexSeal Membrane Air/Vapour Barrier is an air seal membrane designed to prevent the passage of air into or out of the building enclosures when incorporated with building envelope construction. FlexSeal Membrane Air/Vapour Barrier is suitable for use in a variety of wall assemblies and in combination with most construction materials including: concrete, masonry, metal and wood/gypsum sheathing.

| Coverage | In 914 mm (36 in) width rolls, average coverage of 21.90 m² (236 ft²) per roll. In 457 mm (18 in) width rolls, average coverage of 20.6 m² (222 ft²) per carton (2 rolls). Quantities based on side laps of 51 mm (2 in). For estimating purposes a wastage factor of 3% should be included to account for misaligned laps, reinforcing requirements and repairs. |

| Method | Results | |

|---|---|---|

| Thickness | ASTM D3767 Method A | 1 mm (40 mils) |

| Minimum Tensile Strength (Membrane) | ASTM D412 (die C) (Modified) | 2.8 MPa (400 psi) |

| Minimum Tensile Strength (Film) | ASTM D412 (die C) (Modified) | 34.5 MPa (5000 psi) |

| Minimum Elongation (To Failure of Rubberized Asphalt) | ASTM D412 (die C) (Modified) | 200% |

| Pliability (1) @ -32°C (-25°F) | ASTM D1970 | |

| Pliability (1) @ -43°C (-45°F) | ASTM D1970 | Pass |

| Crack Cycling, 6 mm (1/4 in) (2) @ -32°C (-25°F) | Durabond B136 | No effect |

| Joint Cycling, 25 mm (1 in) (3) @ -26°C (-15°F) | Durabond B135 | No effect |

| Minimum Puncture Resistance (Membrane) | ASTM E154 | 178 N (40 lbf) |

| Lap Peel Adhesion (4) @ 4°C (40°F) | ASTM D1876 (Modified) | - |

| Lap Peel Adhesion (4) @ -4°C (25°F) | ASTM D1876 (Modified) | 1505 N/m width (8.6 lbf/in width) |

| Maximum Permeance to Water Vapour Transmission (Membrane) | ASTM 396 (Method B) | 2.9 ng/Pa.s.m² (0.05 Perms) |

| Air Permeance of In Place Membrane [Air Pressure @75 Pa (0.02 in Hg)] | ASTM E283 | 0.000 08 L/s.m² (0.000 004ft³/min.ft²) |

| Resistance to 3000 Pa (0.89 in Hg) | ASTM E330 | No change in air permeance value |

| Water Absorption (Weight gain @ 24 hrs) | ASTM D570 | 0.1% |