Uraflex Traffic Bearing Waterproofing System is a high-performance parking & vehicular deck protective coating system. Uraflex Traffic Bearing Waterproofing System is engineered to waterproof and protect concrete slabs from harsh environmental conditions and salt contamination. The system is formulated with a combination of highly elastomeric polyurethane technology allowing the system to bridge post application cracks and a durable, aggregate laden topcoat to withstand heavy vehicular traffic.

- High abrasion resistant and elastomeric

- Chemically resistant coating

- Maintains elasticity at very low temperatures

- Outstanding penetrating adhesion to concrete

- Bridges crack up to 1/16" (1.6mm)

- Non-skid and decorative

- Waterproof

- Potential LEED credits (Renewable Materials)

- Odour and Solvent free; minimal disturbance to tenants

- UV resistant topcoat available

- Easy to clean

Uraflex Traffic Bearing Wateproofing System is intended for use as a protective waterproofing parking deck coating system for the protection of concrete slabs in parking structures, pedestrian walkways and plaza decks. It is ideal for parking decks, ramps & drive ailes, parking garages, plaza and exposed decks, terraces and balconies (See Uraflex 360/375 UV Balcony System)

| PROPERTIES | URAFLEX 360NP MEMBRANE |

URAFLEX 361 TOPCOAT |

| Colour | Light Grey |

Please see Durex® Colour Selection Guide for available colour options. |

| Resin Type | Polyurethane/Hybrid polyol |

Polyurethane |

| Mix Ratio |

|

|

| Coverage | 80 ft2/gal @ 20 mils DFT |

See Chart |

| Cure Time @ 35-40°C |

|

|

| Pot Life @ 23°C | 20 minutes |

25 minutes |

| Recommended Film Thickness | 20 mils DFT |

15-25 mils DFT |

| Recycled Content | 51% |

60% |

| TEST | METHOD |

URAFLEX 360NP BASECOAT |

URAFLEX 361 TOPCOAT |

| Percent Solids | ASTM D7232-06 |

99% |

100% |

| V.O.C. | ASTM D3960 |

5 g/L |

0 g/L |

| Specific Gravity | ASTM D333 |

1.19 ± 0.05 g/L |

1.25 ± 0.05 g/L |

| Viscosity (Brookfield, 23°C) | ASTM D2196 |

3,300 cps |

1,500 cps |

| Abrasion Resistance |

|

|

|

| Tensile Strength | ASTM D412 |

2,500 psi |

3,000 psi |

| Adhesion (Pull Off) | ASTM D4541 |

400 psi (failure at concrete) |

- |

| Elongation | ASTM D412 |

900% |

60% |

| Flexural Modulus | ASTM D522 |

|

- |

| Adhesion in Peel | ASTM C957 |

Pass |

|

| Crack Bridging | ASTM C957 |

Pass |

|

| Low Temperature Flexibility | 1/8” mandrel @ -26°C ASTM C957 |

Pass |

|

| Water Absorption | ASTM D570 |

Pass |

|

| Water Vapour Transmission | ASTM E96-Procedure B |

|

0.29 metric perms |

| Water Vapour Permeability | ASTM E 96 |

|

|

| Water Vapour Permeance | ASTM E 96 |

|

|

| Shore Hardness | ASTM D 2240 |

67 (Shore A) |

95 / 70 (Shore A / D) |

| Chemical Resistance | ASTM D 412 |

Pass |

Pass |

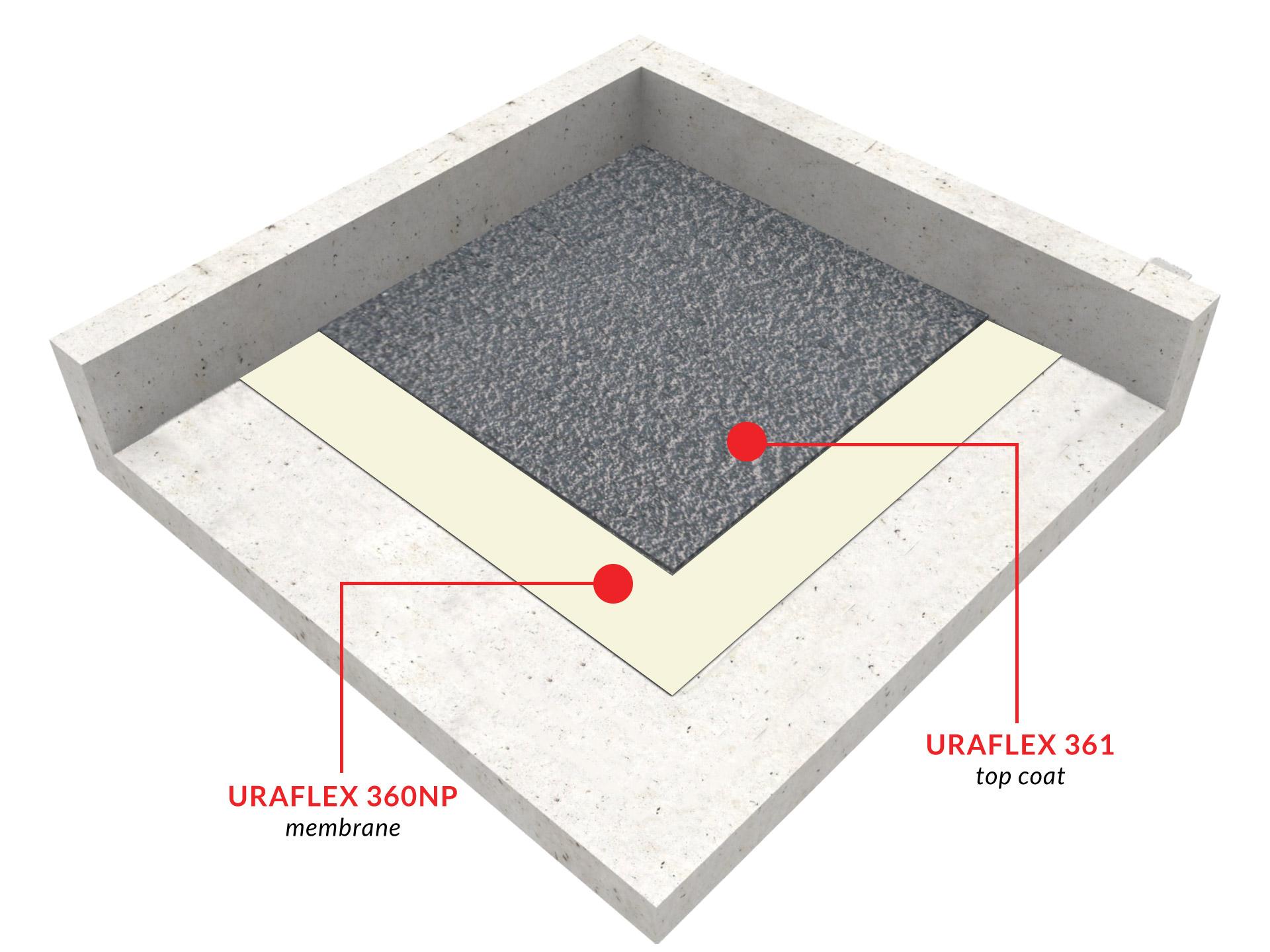

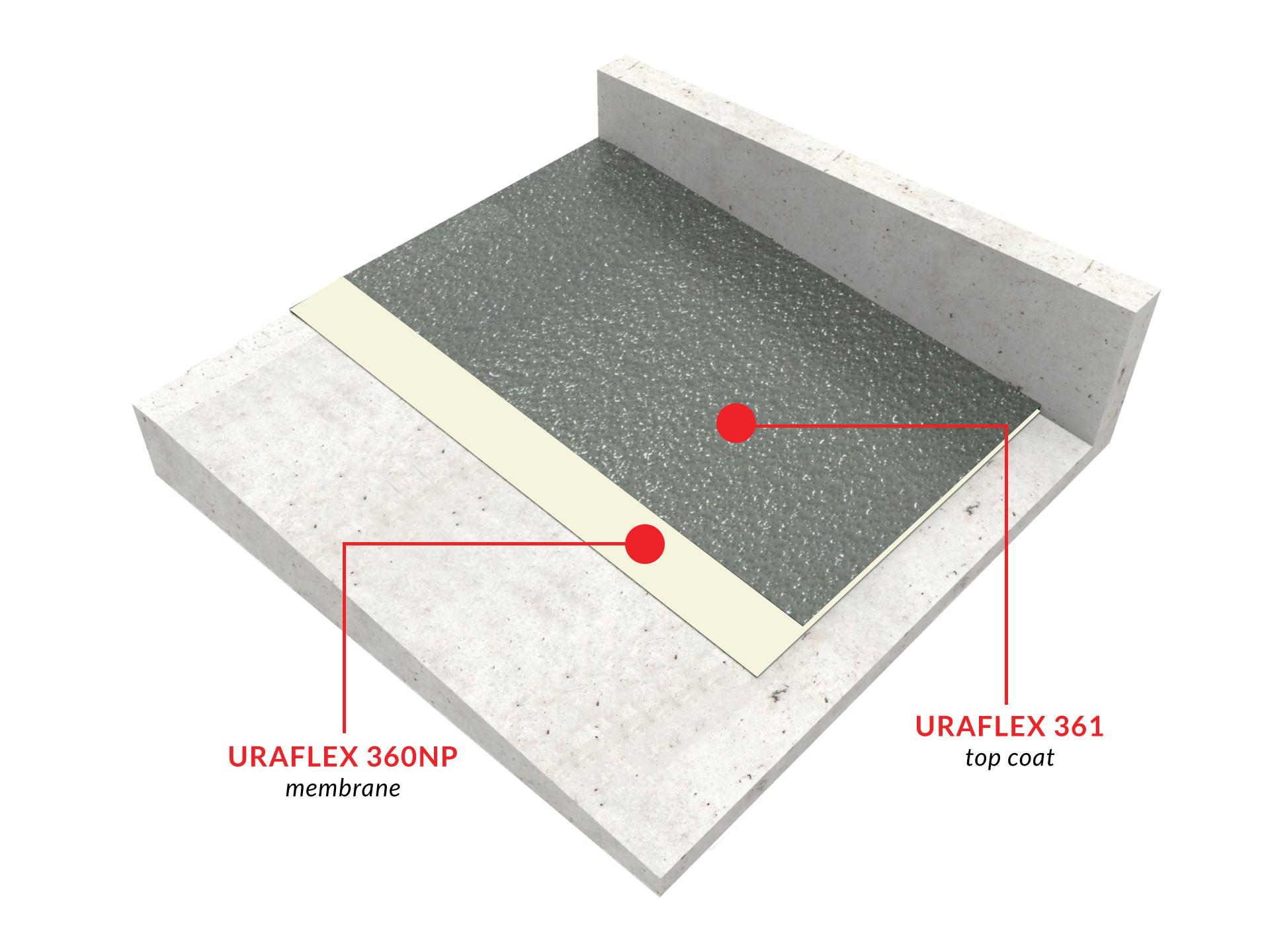

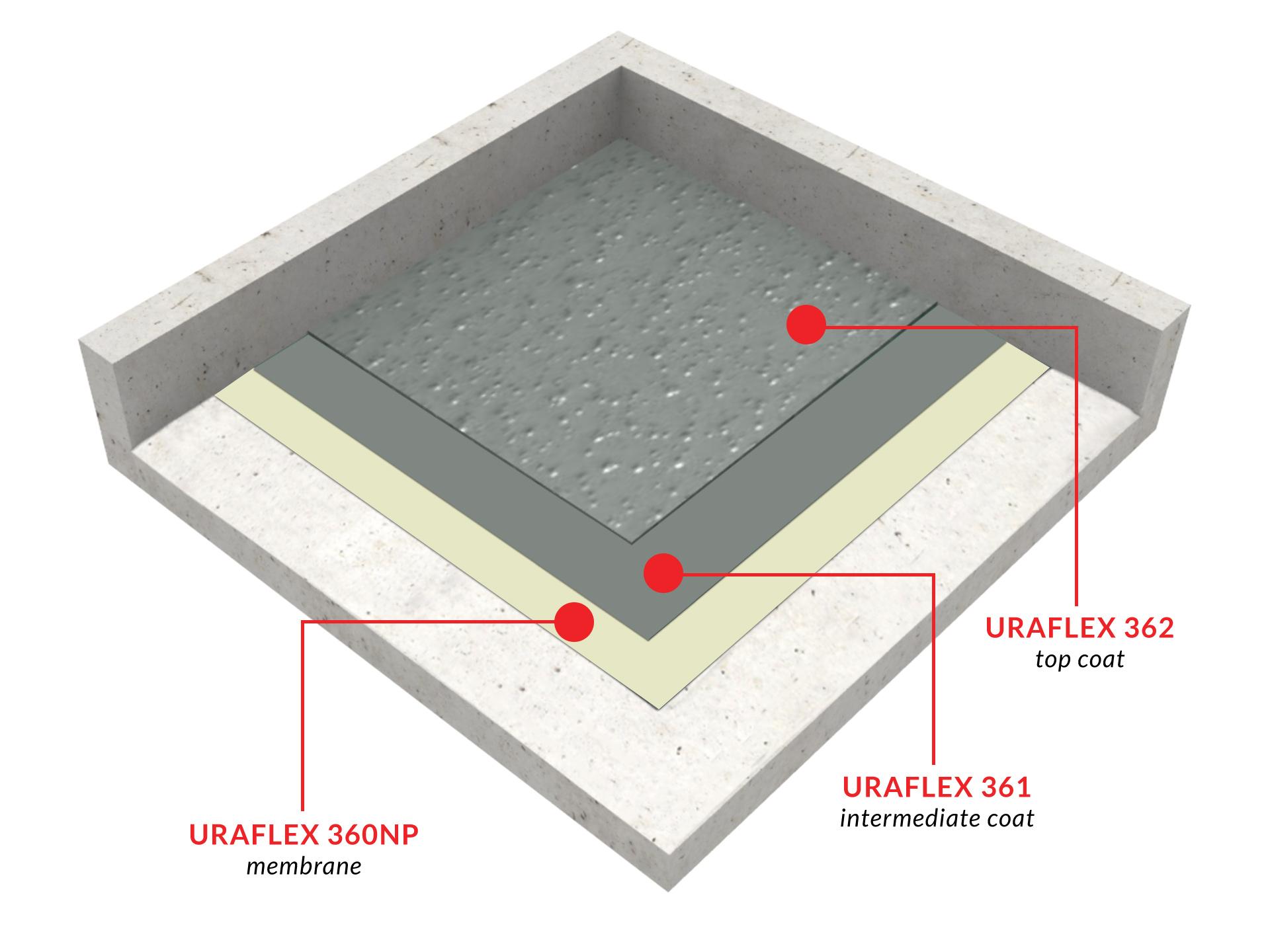

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Membrane | ||

| Top Coat | ||

| Heavy Duty Top Coat | Optional |

|

| UV Resistant Top Coat | Optional |