50 SF / Bag @ 1/8" Thickness

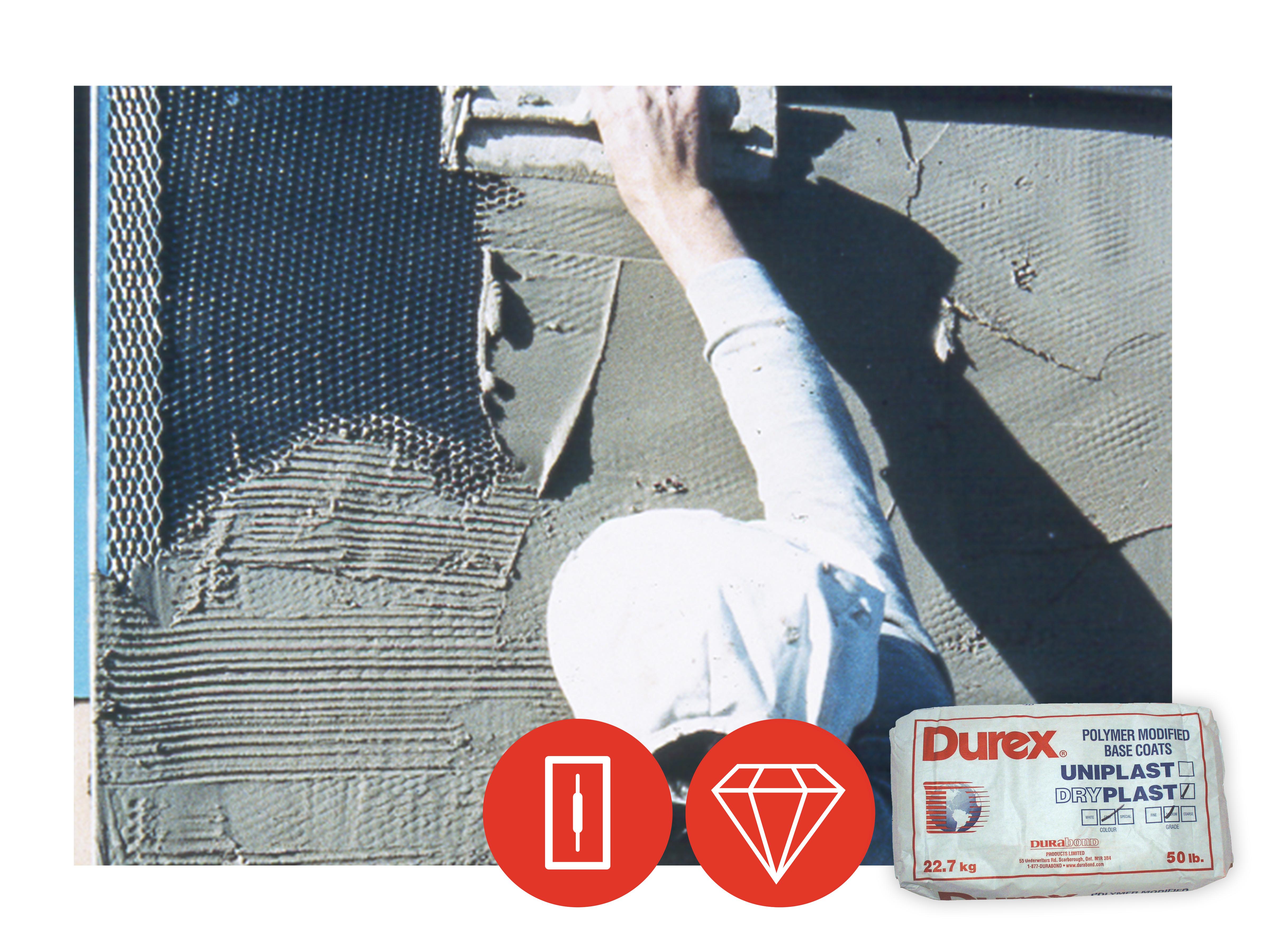

Dryplast is a glass fibre reinforced, Portland cement, plaster mix formulated with numerous ideal features to facilitate and simplify its application. It is available in both medium and coarse grades.

- User friendly premix which requires only the addition of potable water.

- Excellent workability.

- Maximum crack control.

- Maximum quality control.

- Minimum mixing time.

- Low cost.

- Consistency and ease of duplication of mixes.

- Rated ‘non-combustible’, thus meeting the National Building Code as a material to protect foamed plastic insulation for exterior applications.

Dryplast Medium grade can be used as the scratch and base coats for Lite Coat and Stucco Lite Systems. Dryplast Coarse grade can be used as the scratch and base coats for Stucco Wall and High Impact Systems.

| Product Type | Polymer modified fibre reinforced plaster base mix | |

| Appearance | Cementitious powder mix and aggregates | |

| Toxicity | CAS-Registry No. 65997-15-1 (contains Portland Cement) | |

| Density | 1290 kg/m³ | |

| Bulk pot life | 1 hr to 2 hrs (depending on ambient conditions and type of polymer used) | |

| Coverage |

| |

| Mixing Ratio |

|

| Method | Results | |

|---|---|---|

| Compressive strength | ASTM C109 | 31.03 MPa (45000 psi) |

| Flexural strength | ASTM C293 | 13.10 MPa (1900 psi) |

| Shear bond adhesion | ASTM C882 | 4.06 MPa (590 psi) |

| Tensile strength | ASTM C190 | 6.55 MPa (950 psi) |

| Non-combustible | CAN4-ULC-S114 | Rated non-combustible |