0.74 m2 (8 ft2) per board

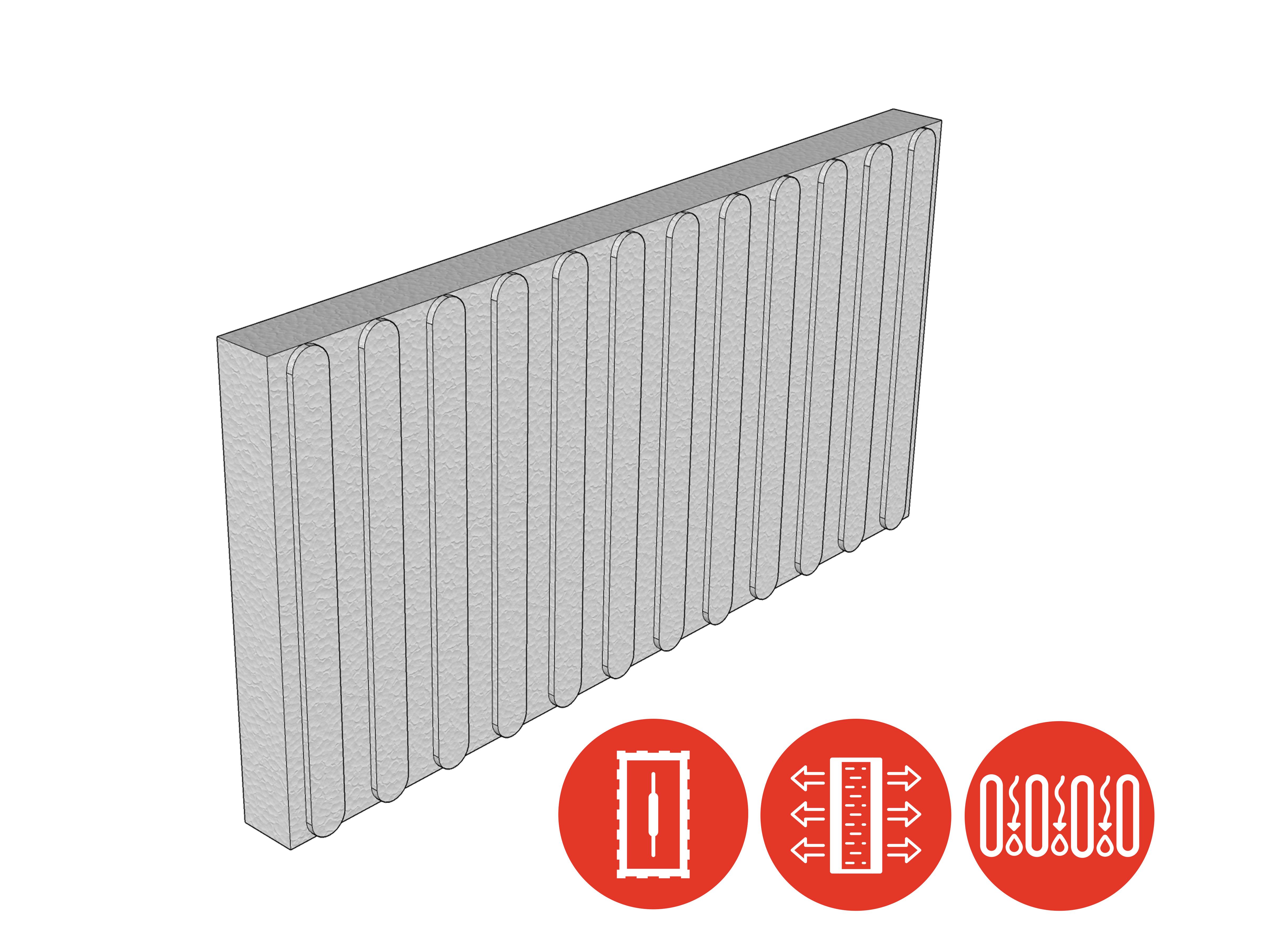

Quantum Select Insulation Board is a Type I Expanded Polystyrene Insulation Board (as per ULC-S701 and ASTM-C-578) featuring geometrically defined drainage cavities on the back side of the insulation board, intended for use in Quantum Select family of EIFS Systems. Quantum Select Insulation is supplied in sheets which are 610 mm (2ft) x 1220 mm (4 ft), in thicknesses from 50.8 mm (2") to 152 mm (6") in increments of 12.5 mm (1/2") and available in both Type I EPS and Type II EPS. Quantum Select Insulation can be applied over any substrate approved for our Quantum Select family of EIFS Systems and attached by chemical adhesive bond or by mechanical fasteners as specified. The sheets are not to be applied directly to framing members when part of any Quantum Select family of EIFS System. All test results given herein, or any of those in our EIFS Systems are specific to use Quantum Select insulation. Substitution voids all tests results and systems warranties offered. Special aesthetic shapes supplied by others are not incorporated in the EIFS System warranty.

- Moisture does not weaken EPS

- GDDC Factor 47% (Geometrically Defined Drainage Cavity)

- CI factor 0.65 RSI (R 3.9) per inch (Continuous Insulation)

- CI factor 0.70 RSI (R 4.0) per inch Type II EPS (Continuous Insulation)

- 10mm drainage cavity

- Thermal protection

- EPS contains no CFC’s, HCFC’s or HFC’s

- Chemically inert

- EPS is a recyclable material

- Waste to Energy safe

For use as the Exterior insulation in all Quantum Select family of EIFS Systems. The use of the expanded polystyrene is governed by the applicable building codes.

| Dimensional Tolerances | ± 1.6 mm (1/16") | |

| Bowing Tolerances | ± 0.8 mm (1/32") | |

| Available Thicknesses | 50.8 mm (2") to 152 mm (6") in 12.5 mm (1/2") increments | |

| Material |

| |

| Coverage | 0.74 m2 (8 ft2) per board |

| Method | Results | |

|---|---|---|

| Density | ASTM D1622 |

|

| Thermal Resistance | ASTM C518 |

|

ASTM STP1320 |

| |

| Compressive Strength | ASTM D1612 |

|

| Flexural Strength | ASTM C203 |

|

| Water Absorption | ASTM D2842 |

|

| Dimensional Stability | ASTM D2126 |

|

| Limiting Oxygen Index | ASTM D2863 |

|