0.74 m2 (8 ft2) per board

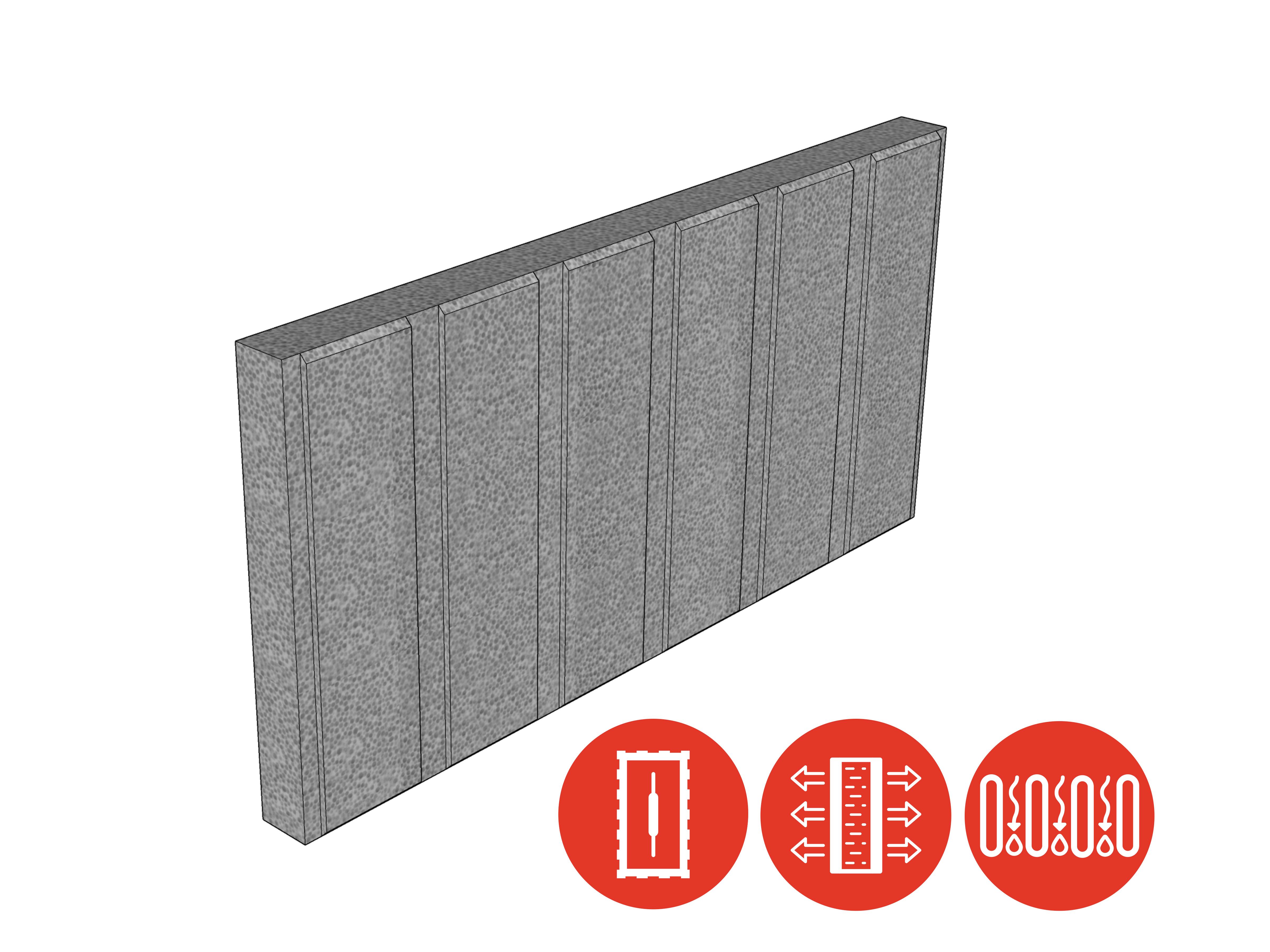

Insulite Select Insulation Board is a Graphite enhanced Expanded Polystyrene Insulation Board (as per ULC-S701 and ASTM-C-578). Similar to the popular Quantum Select Insulation board it features geometrically defined drainage cavities on the back side of the insulation board, intended for use in Insulite Select family of EIFS Systems. Insulite Select Insulation is supplied in sheets which are 610 mm (2ft) x 1220 mm (4 ft), in thicknesses from 50.8 mm (2") to 152 mm (6") in increments of 12.5 mm (1/2"). Forming the thermal component of the Insulite Select family of EIFS Systems and attached by mechanical fasteners as specified.

The Insulite Select insulation board facilitates compliance to the National Energy Code for Buildings NEBC with Continuous Insulation (CI) factors ranging from:

2" (50mm) CI of 1.8 RSI , to

6" (150mm) CI of 5.0

- High Thermal Resistance

- GDDC Factor 25% (Geometrically Defined Drainage Cavity)

- CI factor 0.88 RSI (R 5.0) per inch (Continuous Insulation)

- 10mm drainage cavity

- Moisture Resistant and Vapour-open

- Graphite contains no CFC’s, HCFC’s or HFC’s

- Chemically inert

- Graphite is a recyclable material

For use as the Exterior insulation in all Insulite Select family of EIFS Systems where highest thermal resistance is required in a controlled thickness of cladding system

| Dimensional Tolerances | ± 1.6 mm (1/16”) | |

| Bowing Tolerances | ± 0.8 mm (1/32”) | |

| Available Thicknesses | 50.8 mm (2”) to 152 mm (6”) in 12.5 mm (1/2”) increments | |

| Material | Graphite - 1.0 lb/ft3 (Virgin) Density Graphite enhanced Expanded Polystyrene | |

| Coverage | 0.74 m2 (8 ft2) per board |

| Method | Results | |

|---|---|---|

| Density | ASTM C303 | 1.25 lb/ft3 (20.0 Kg/m3 ) |

| Thermal Resistance | ASTM C518 | 5.0 ft2 ·h·°F/BTU – (R-Value / 1” @ 75°F) 0.88 m2·°K/W – (RSI / 25mm @ 24°C) 5.2 ft2 ·h·°F/BTU – (R-Value / 1” @ 40°F) 0.92 m2·°K/W – (RSI / 25mm @ 5°C) |

| Flame Spread & Smoke Developed | ASTM E84 | < 25 Flame Spread Index < 450 Smoke Developed Index |

| Compressive Strength | ASTM D1612 | 13 psi (90.0 kPa) at 10% Strain |

| Flexural Strength | ASTM C203 | 32 psi (220.0 kPa) |

| Water Absorption | ASTM C272 | 1.1 % (% by volume) (total immersion) |

| Water Vapour Permeance | ASTM E96 | 178.0 ng/Pa.s.m2 (3.1 perms) |

| Dimensional Stability | ASTM D2126 | -1.5 % (linear change) |

| Maximum use Temperature | 1650F (740C) |