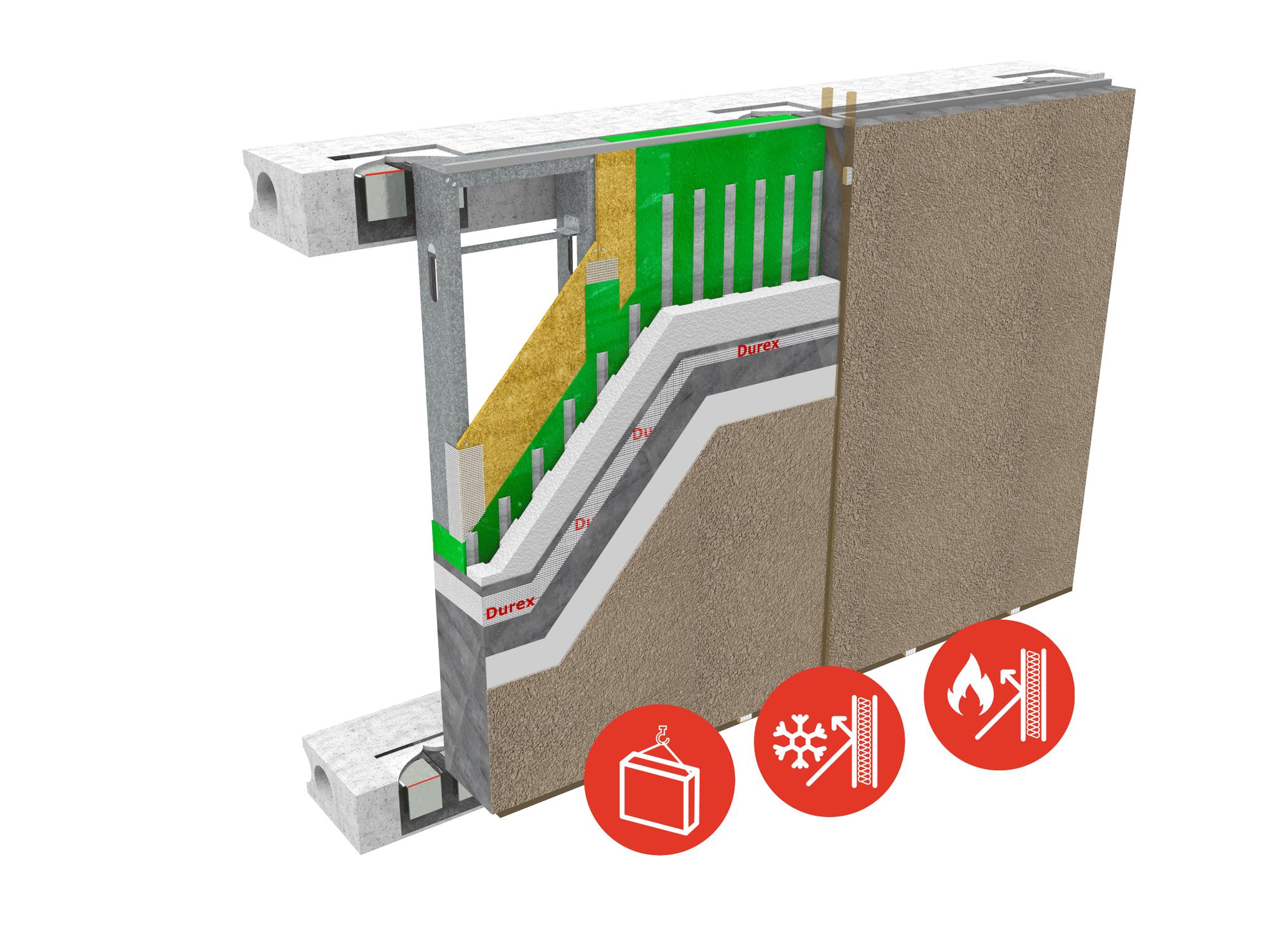

IBS Quantum Select is not just a cladding – it is a unitized curtain wall system that integrates the performance of several wall components for providing the essential, environmental separation controls of heat / air / moisture / fire, strength, durability and aesthetics, all in one lightweight, energy efficient, cost-effective wall assembly. IBS is the new trend in energy efficient exterior curtain walls. It brings significant advancements to the conventional, architecturally limited, glass, stone or other material curtain walls through a water-managed, pressure-moderated and energy efficient wall system.

- Pre-engineered Lightweight Panel Design

- Speed of Construction

- Pressure Moderated Rain Screen Design

- Air/Water tight Building Envelope Design

- Geometrically Defined Drainage Cavity (GDDC)

- Superior Thermal Performance

- 1 Hour Fire Rated System ULC W-489

- 2-Hour Fire Rated System ULC W-485

- Non-combustible base coats

- Continuous Insulation - (CI) Factor = 0.65 RSI/in (Type1 EPS) 0.70 RSI/in (Type 2 EPS)

IBS Quantum Select provides the best wall solution for all types of construction, be it institutional, residential, commercial, industrial and/or temporary. IBS features a lightweight, wall assembly panel with a high strength to weight ration, eliminating the need for super structural elements such as beams and columns. IBS’s lightweight and flexibility make it an ideal solution for applications in high seismic/wind zones.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 & CAN/ULC S101 CAN/ULC S134 |

Non-Combustible Lamina Fire Test of Exterior Wall Assemblies |

| Building Code Conformance: | Part 3 |

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| INSULATION: |

Durex Quantum Select Type I Durex Quantum Select Type II |

CAN/ULC S701 |

Thermal Resistance GDDC Factor 0.65 RSI (R 3.9) per inch 47% 0.70 RSI (R 4.0) per inch 47% |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers Durex Green Guard Durex Ectoflex Air Barriers Durex Flexcrete Durex AirStop Durex Dur-A-Mastic 100 Durex Blue Shield |

ASTM E96 – Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B 11 ng/Pa.s.m2 48 ng/Pa.s.m2 18 ng/Pa.s.m2 91 ng/Pa.s.m2

400 ng/Pa.s.m2 972 ng/Pa.s.m2 185 ng/Pa.s.m2 505 ng/Pa.s.m2 248 ng/Pa.s.m2 645 ng/Pa.s.m2 107 ng/Pa.s.m2 268 ng/Pa.s.m2 |

| INSULATION ADHESIVE: | Durex Flexcrete Durex Monobase Durex VCA 3.0 |

ASTM D1623 Adhesion Properties (Refer to product specific Technical Data Sheet for more detailed data) |

1.12 MPa (162 psi) 1.38 MPa (200 psi) 1.02 MPa (148 psi) |

| LAMINA: | Impant Resistance Durex Fiberglass Mesh (Note: Impact resistance level is directly related to the weight and layers of Fiberglass mesh used in the lamina) |

ASTM E2486 – Impact Resistance (Refer to Table 1.5.9 of the IBS Quantum Select Specifications for detailed selection chart for guidance on level of impact resistance required) |

Retention Retention Physical Performance Standard 3 N.m 10 N.m PASS Intermediate 8 N.m 15 N.m PASS High 13 N.m 20 N.m PASS Ultra High 20 N.m 30 N.m PASS Extreme 25 N.m 40 N.m PASS |

Base Coat Durex Uniplast/Acrybond “S” Durex Monobase |

CAN/ULC S114 Noncombustibility |

Rated Noncombustible Rated Noncombustible |

|

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report #13103-R for moredetailed data) |

Durex Architectural Coatings Meet and exceed all requirements

|

| PERFORMANCE: | Fire Protection |

(Refer CCMC Evaluation Report # 13103-R for complete detailed performance data) CAN/ULC S101 & CAN/ULC S114 (Compliance to NBC 3.2.3.8(1) (b) ) CAN/ULC S101 (Fire Resistance rated Assemblies)

CAN/ULC S134 (Compliance to NBC 3.1.5.5) |

Rated as non-combustible cladding ULC design EW21/ EW22

1 hr. FR rating ULC design W489 (Load Bearing) 2 hrs. FR rating ULC design W485 (Load Bearing) 2 hrs. FR rating ULC design W456 (Non-Load Bearing)

Intertek listing # DPL-WEIFS 30-01 |

Wind Load Resistance |

ASTM E330 – sustained

ASTM E330 – cyclic

ASTM E330 – blow-out |

-2.5 kPa for 60min. – no visible damage to any of the wall components -600 cycles alt. 0 to -2.5kPa – no visible damage to any of the wall components -3.75kPa applied for 10 sec. – no visible damage to any of the wall components - max. pressure 7.12 kPa |

|

Water Tightness |

ASTM E331 |

400 Pa pressure difference for 15 min. – no water penetration through the exterior surface finish |

|

System Compliance |

CCMC Technical Guide for EIFS CAN/ULC S716.1 EIFS Materials & System |

CCMC Evaluation Report # 13103-R Durex IBS Quantum Select is fully compliant with: -CAN/ULC S716.1 Materials & System -CAN/ULC S716.2 Installation of Components & WRB -CAN/ULC S716.3 Design Application |

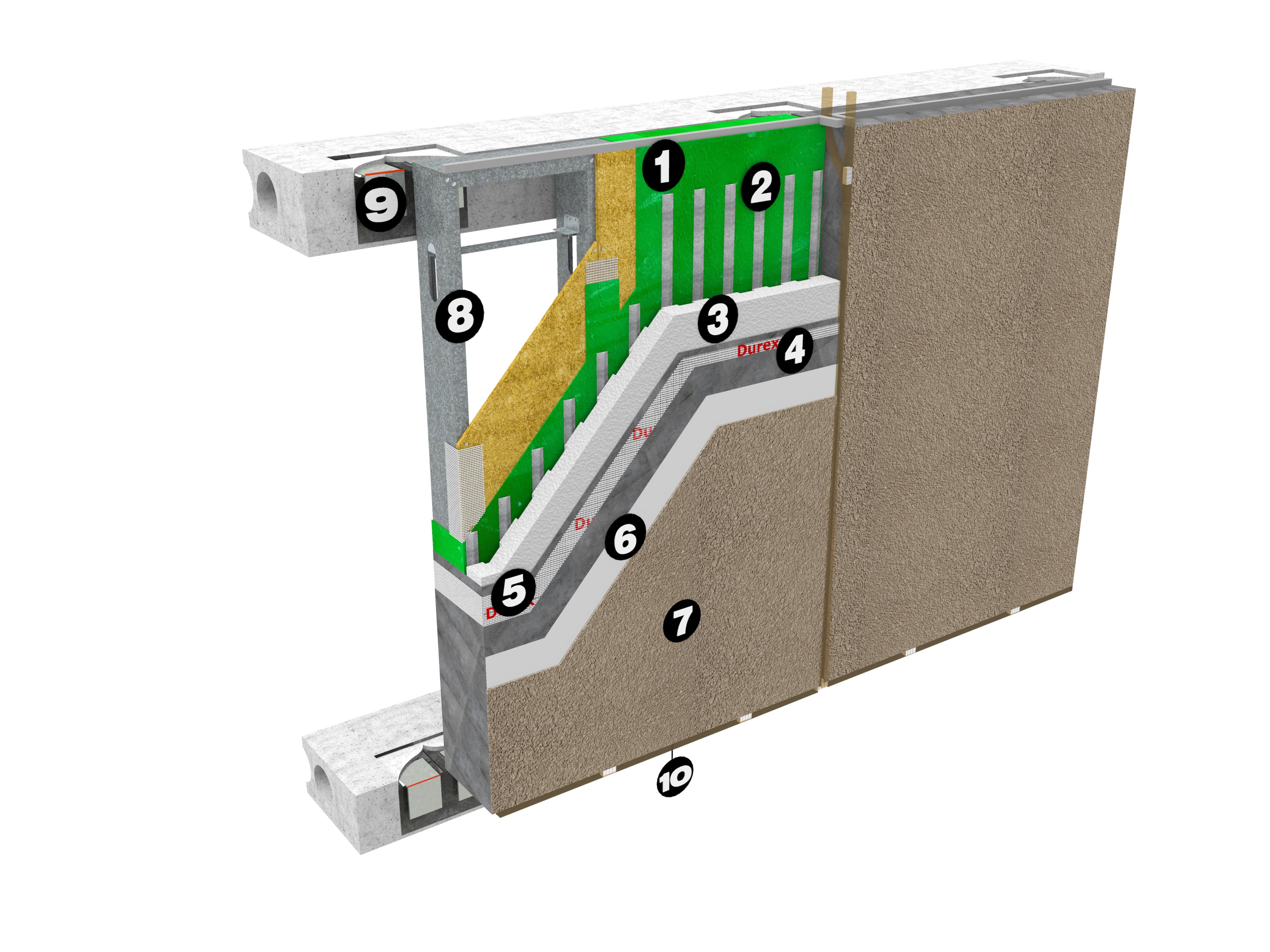

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Transition Membrane | ||

| Insulation Adhesives | ||

| Rigid Insulation (Exterior) | ||

| Base Coat | ||

| Reinforcing Mesh | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard |