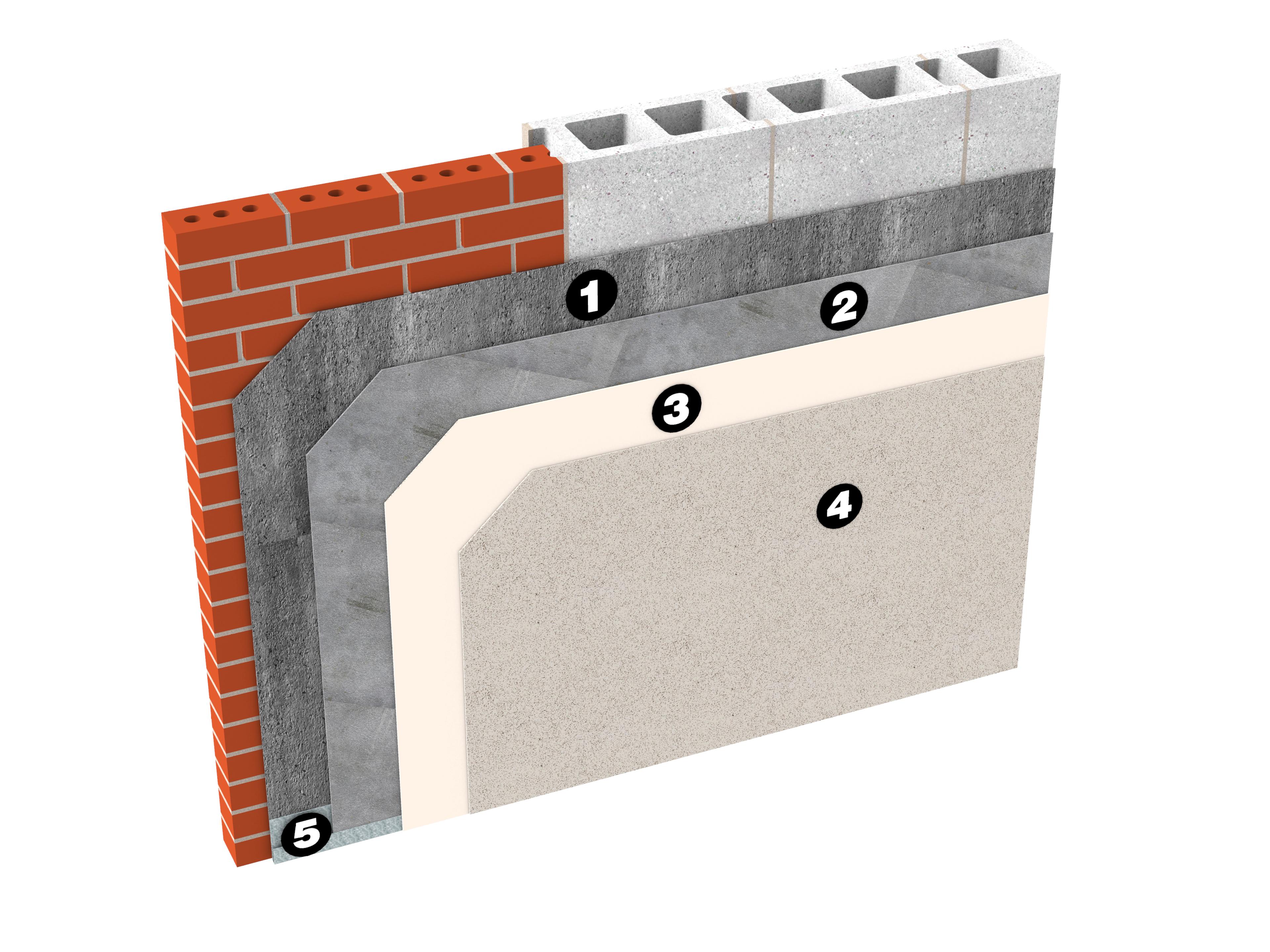

Lite Coat is a non-insulated non-combustible direct applied wall coating system. The system consists of one or two base coats, (depending on substrate deviation rectification required), The finish texture coat can be selected from any one of the available Durex® Architectural Coatings. The system is typically not reinforced but as an option the scratch coat can be reinforced with synthetic fibers.

- Economical

- Easy to install

- Non-combustible

- High impact resistance

- Excellent for both new and retrofit work

Lite Coat is an excellent cost effective coating system for both new and restoration work. It can all be used as a parging system, best suited for concrete, masonry or solid & clean old plaster substrates.

| Building Code Conformance | Classification |

Category 2 |

Non-Combustible Stucco cladding System |

Part 3 |

|

|

|

Part 5 |

Section 5.6.1 |

Protection from Precipitation |

|

Part 9 |

Section 9.27.2 |

Required Protection from Precipitation |

|

| SUBSTRATE: | Masonry |

New or existing masonry |

must be clean & sound (refer to system specifications for further details |

| WATER RESISTIVE BARRIER: | Not applicable |

Durex Lite Coat MASONRY imparts water repellant properties |

|

| REINFORCEMENT: | Not applicable |

Additional reinforcement can be achieved by adding synthetic fibers to the scratch coat |

|

| BASE COAT: |

|

|

|

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report # 13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE: | Shear Bond Adhesion |

ASTM C882 |

11.20 MPa (1625 psi) |

Water absorption |

ASTM D570 |

1.9% (Uniplast) |

|

Coefficient of Water Absorption |

CCMC 5.5.1 |

0.0007 kg/(m2.s1/2) (Flecrete) |

|

Tensile Strength |

ASTM C190 |

6.00 MPa (870 psi) |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Base Coat | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard | ||

| Galvanized Trim |