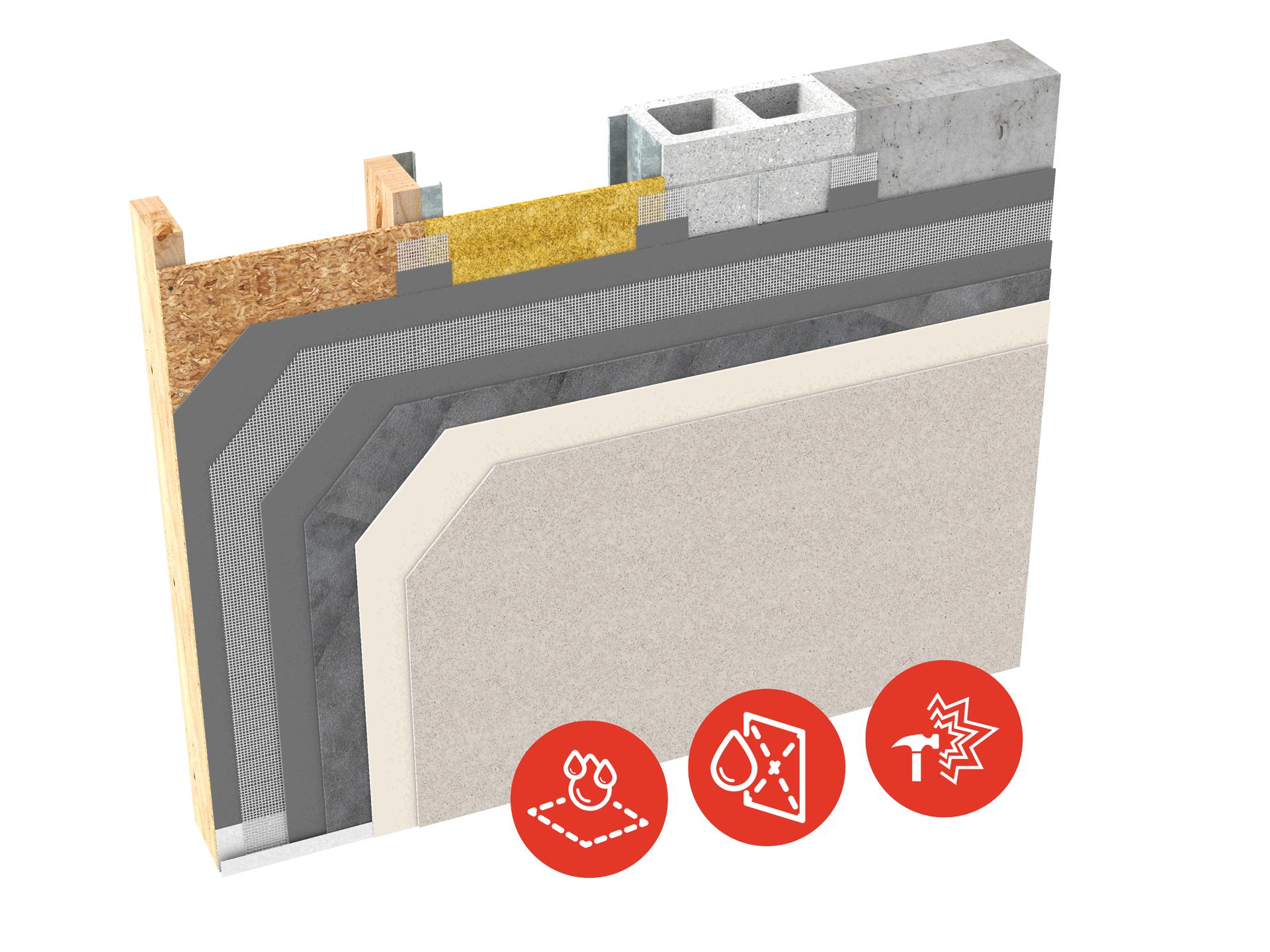

Stucco Lite HM is a non-insulated wall coating system for high moisture areas, specifically designed to control and prevent vapour diffusion from the high moisture environment into the adjacent structure. The system consists of an exclusive cementitious trowel applied vapour barrier coating glass fibre reinforcing mesh, topped with base coats, and a finish texture coat which can be selected from any one of the available Durex® Architectural Coatings.

- Excellent vapour control system

- Easy to apply

- Allows for use of a wide variety of finish textures

- Impact resistant

- Applicable for new and existing construction

Stucco Lite HM system can be used for both new and restoration work. It is highly recommended for use in high humidity areas, especially swimming pools, indoor water parks and high moisture areas.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 (Monobase) & Uniplast |

Noncombustible stucco cladding |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

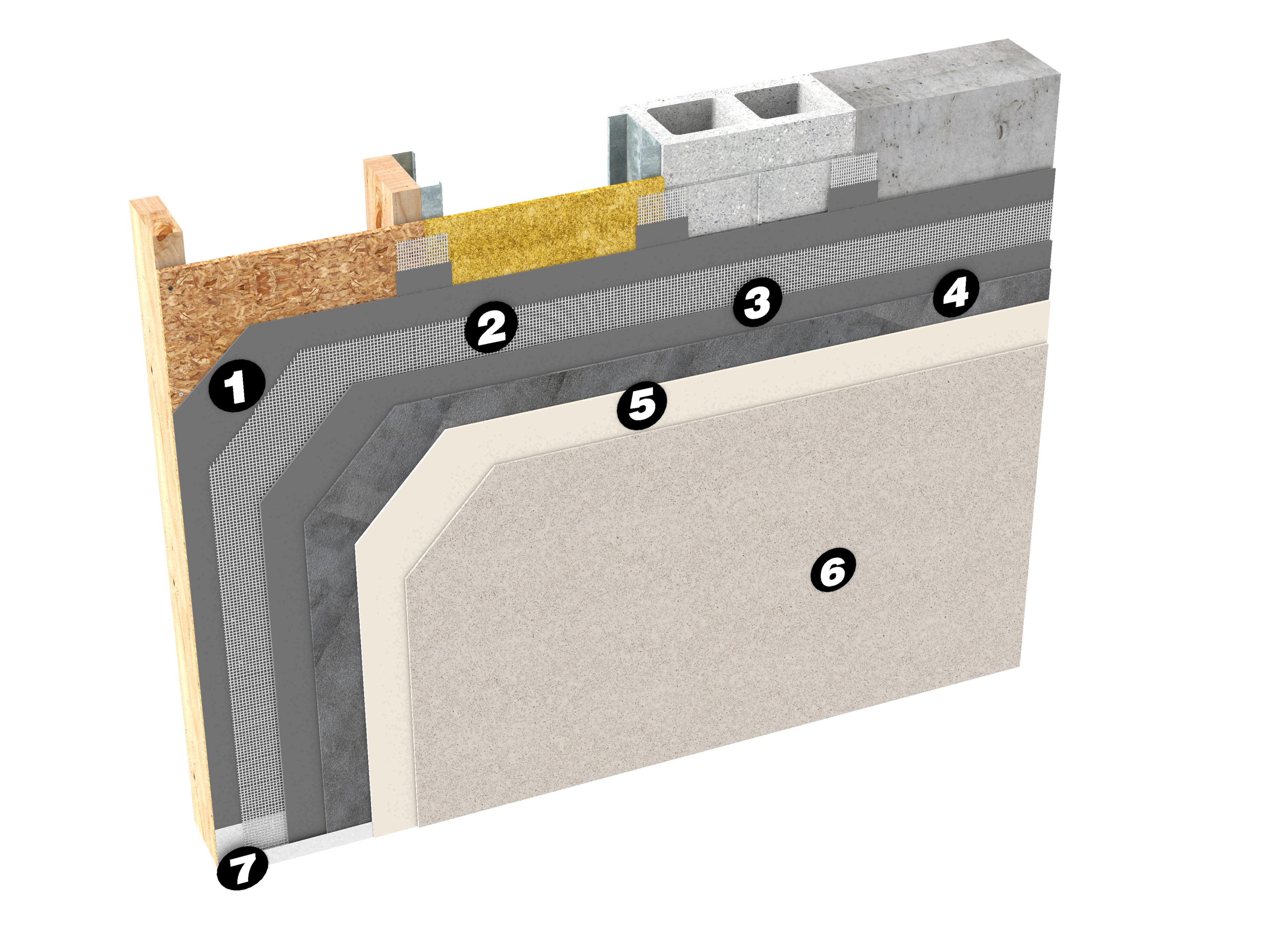

| SUBSTRATE: | - Cementitious Backer Board - Glass Mat Gypsum Sheathing - Concrete |

ASTM C1325 ASTM C1177 |

12.7 mm (1/2”) min. 12.7 mm (1/2”) min. |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers Durex EctoFlex Air Barriers Durex Flexcrete |

ASTM E96 Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) (for best results use two coats of WRB) |

Method A Method B 18 ng/Pa.s.m2 91 ng/Pa.s.m2

400 ng/Pa.s.m2 972 ng/Pa.s.m2 |

| BASE COAT: | - Durex Flexcrete or - Durex Monobase - Durex Uniplast / Acrybond “S” |

CAN/ULC S114 CAN/ULC S114 |

Rated noncombustible Rated noncombustible |

| REINFORCEMENT | Impant Resistance Durex Fiberglass Mesh (Note: Impact resistance level is directly related to the weight and layers of Fiberglass mesh used in the lamina) |

ASTM E2486 – Impact Resistance (Refer to Table 1.5.9 of the Quantum 5.0 Specifications for detailed selection chart or guidance on level of impact resistance required) |

Retention Retention Physical Performance Standard 3 N.m 10 N.m PASS Intermediate 8 N.m 15 N.m PASS High 13 N.m 20 N.m PASS Ultra High 20 N.m 30 N.m PASS Extreme 25 N.m 40 N.m PASS |

| FASTENERS: | -Durex “M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel) |

ASTM B-117 – salt spray DIN 50012 - SO2 exposure FM4470 DIN 50018 SFW |

750 hrs. or better 25+ cycles 30 cycles Pass |

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report # 13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements

|

| PERFORMANCE: | Water Vapour Transmission |

ASTM E96 - EctoFlex |

18 ng/Pa.s.m2 (0.3 perms) method A (one coat) 6 ng/Pa.s.m2 (0.11 perms) method A (two coats) |

Water absorption |

ASTM D570 |

3.58% |

|

Coefficient of Water Absorption |

CCMC 5.5.1 |

0.0007 kg/(m2.s1/2) |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| 2 Layers Water Resistive Barriers (WRB) | ||

| Transition Membrane | ||

| Reinforcing Mesh | ||

| Base Coat | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard | ||

| Galvanized Trim |