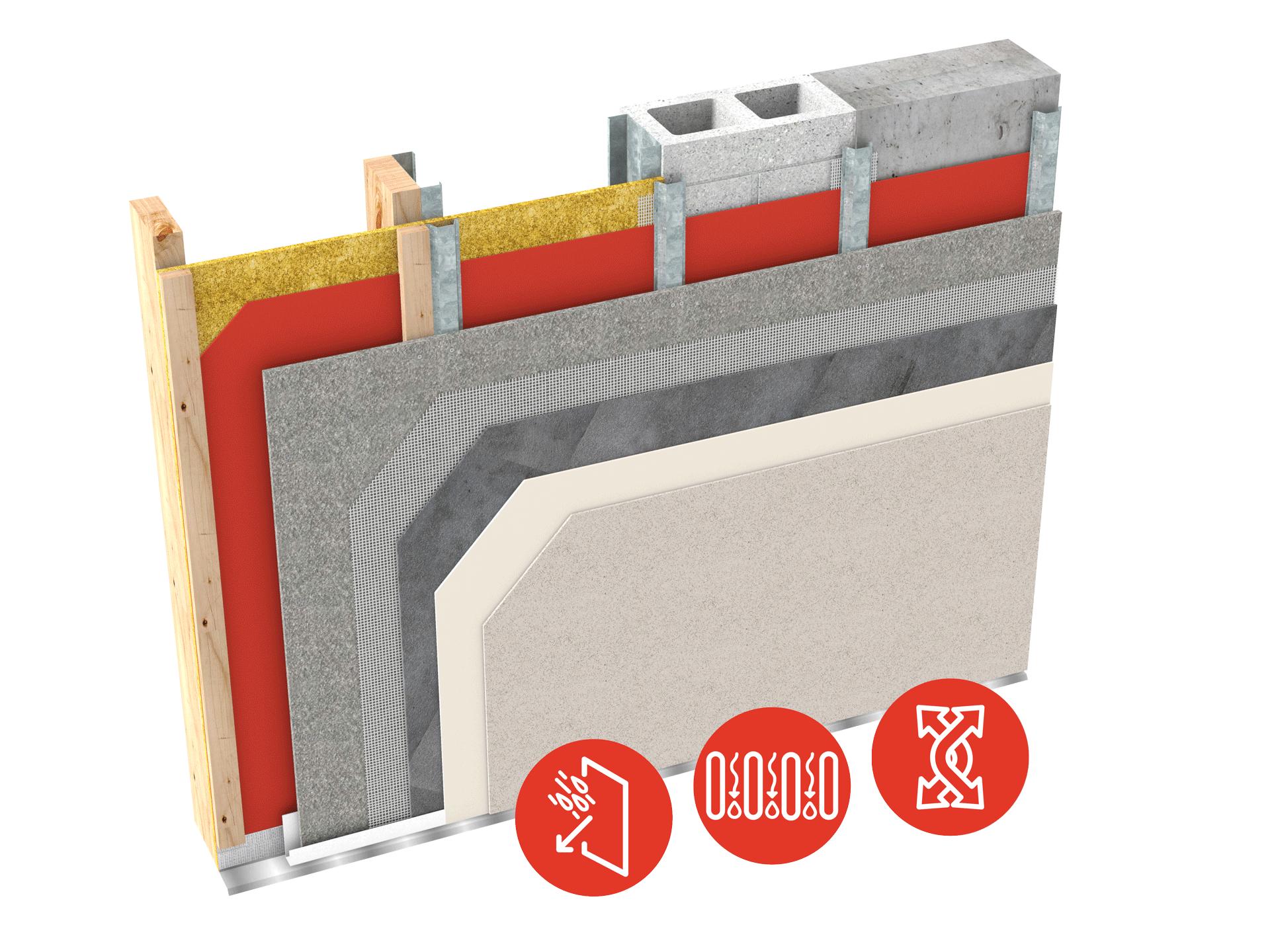

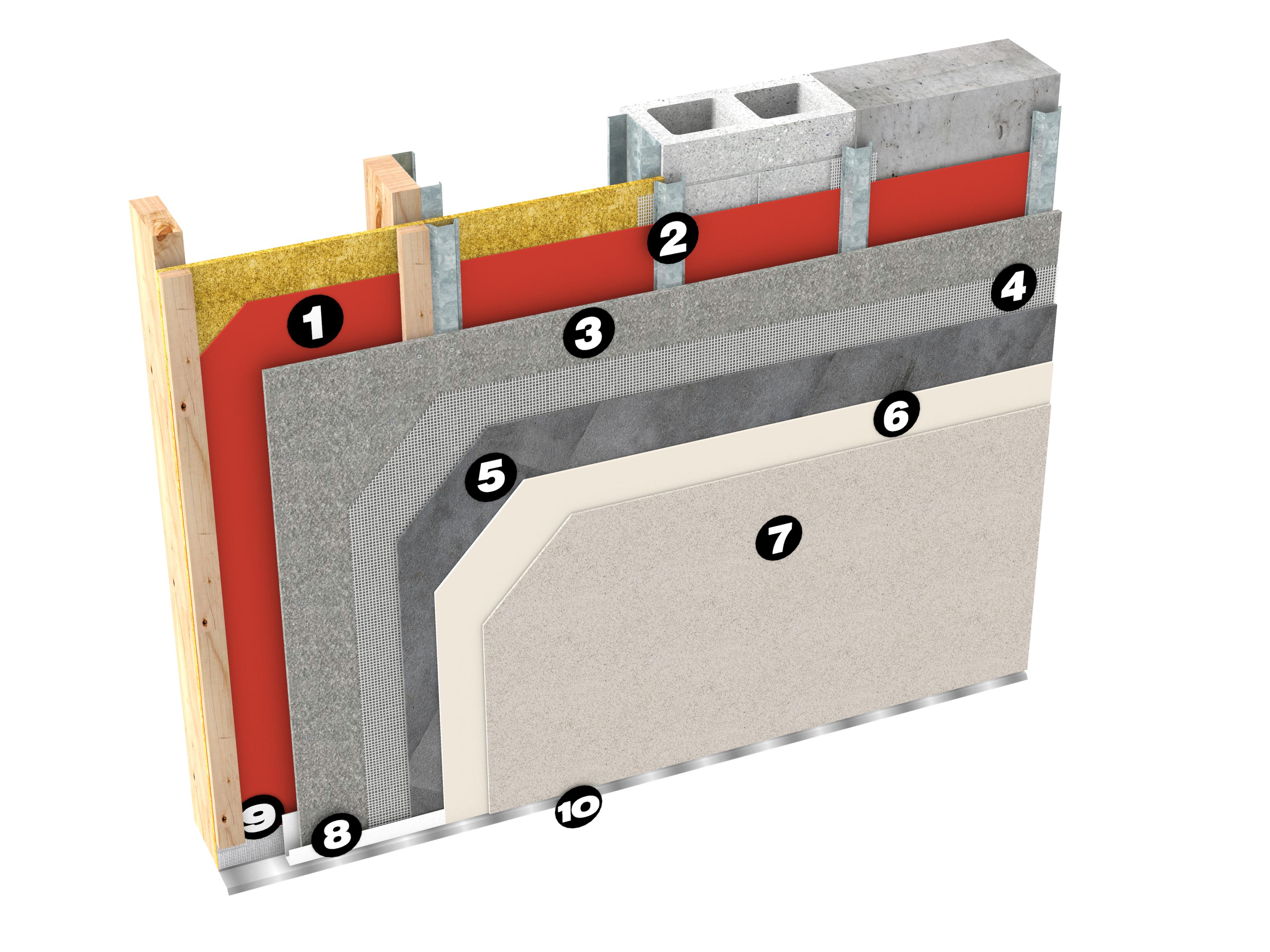

Stucco Lite Rainscreen combines the simplicity of direct applied cladding system with drainage and rainscreen features. Succo lite rainscreen consists of a nail sealable water resistive barrier over the substrate furring to create a drainage cavity and a cement board sheathing coated with a flexible basecoat reinforced with fiberglass mesh throughout to create a code compliant rainscreen drainage cladding system. The finish texture can be selected from any of the available Durex® Architectural Coatings. The cladding system is rated non-combustible cladding meeting the building code requirements for non-combustible construction.

- Improved traditional cladding system

- Positive drainage - rainscreen

- Non-combustible

- High impact resistance

- Cost effective cladding system if no continuous insulation is required

Stucco Lite Rainscreen is suitable for use over a wide range of structurally sound substrates. It is best suited for substrates designed with a deflection ratio lower than L/360 where spatial separation issues require non combustible cladding, typical of residential dwellings with side setbacks less than 600 mm from the property line.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 |

Non-Combustible stucco cladding |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| SYSTEM SHEATHING: | - Cementitious backer Board - Glass Mat Gypsum Sheathing |

ASTM C1325 ASTM C1177 |

12.7 mm (1/2”) min. 12.7 mm (1/2”) min. |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers (consult with a Durabond Representative) Air Barriers Durex Flexcrete Durex AirStop Durex Dur-A-Mastic 100 Durex Flexseal VP |

ASTM E96 Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B n/a n/a

400 ng/Pa.s.m2 972 ng/Pa.s.m2 185 ng/Pa.s.m2 505 ng/Pa.s.m2 248 ng/Pa.s.m2 645 ng/Pa.s.m2 629 ng/Pa.s.m2 972 ng/Pa.s.m2 |

| REINFORCEMENT: | Impant Resistance Durex Fiberglass Mesh (Note: Impact resistance level is directly related to the weight and layers of Fiberglass mesh used in the lamina) |

. ASTM E2486 – Impact Resistance (Refer to Table 1.5.9 of the Stucco Lite RAINSCREEN Specifications for detailed selection chart for guidance on level of impact resistance required) |

Retention Retention Physical Performance Standard 3 N.m 10 N.m PASS Intermediate 8 N.m 15 N.m PASS High 13 N.m 20 N.m PASS Ultra High 20 N.m 30 N.m PASS Extreme 25 N.m 40 N.m PASS |

| BASE COAT: | - Durex Flexcrete or - Durex Monobase - Durex Uniplast / Acrybond “S” |

CAN/ULC S114 CAN/ULC S114 |

Rated noncombustible Rated noncombustible |

| FASTENERS: | -Durex “M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel) |

ASTM B-117 – salt spray DIN 50012 - SO2 exposure FM4470 DIN 50018 SFW |

750 hrs. or better 25+ cycles 30 cycles Pass |

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report #13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE: | Water Vapour Transmission |

ASTM E96 - Flexcrete |

400 ng/Pa.s.m2 (7.0 perms) method A 972 ng/Pa.s.m2 (17.0 perms) method B |

Water absorption |

ASTM D570 |

4.85% (Flexcrete) |

|

Coefficient of Water Absorption |

CCMC 5.5.1 |

0.0007 kg/(m2.s1/2) |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Bracing | ||

| Cement Board | ||

| Reinforcing Mesh | ||

| Base Coat | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard | ||

| Galvanized Trim |