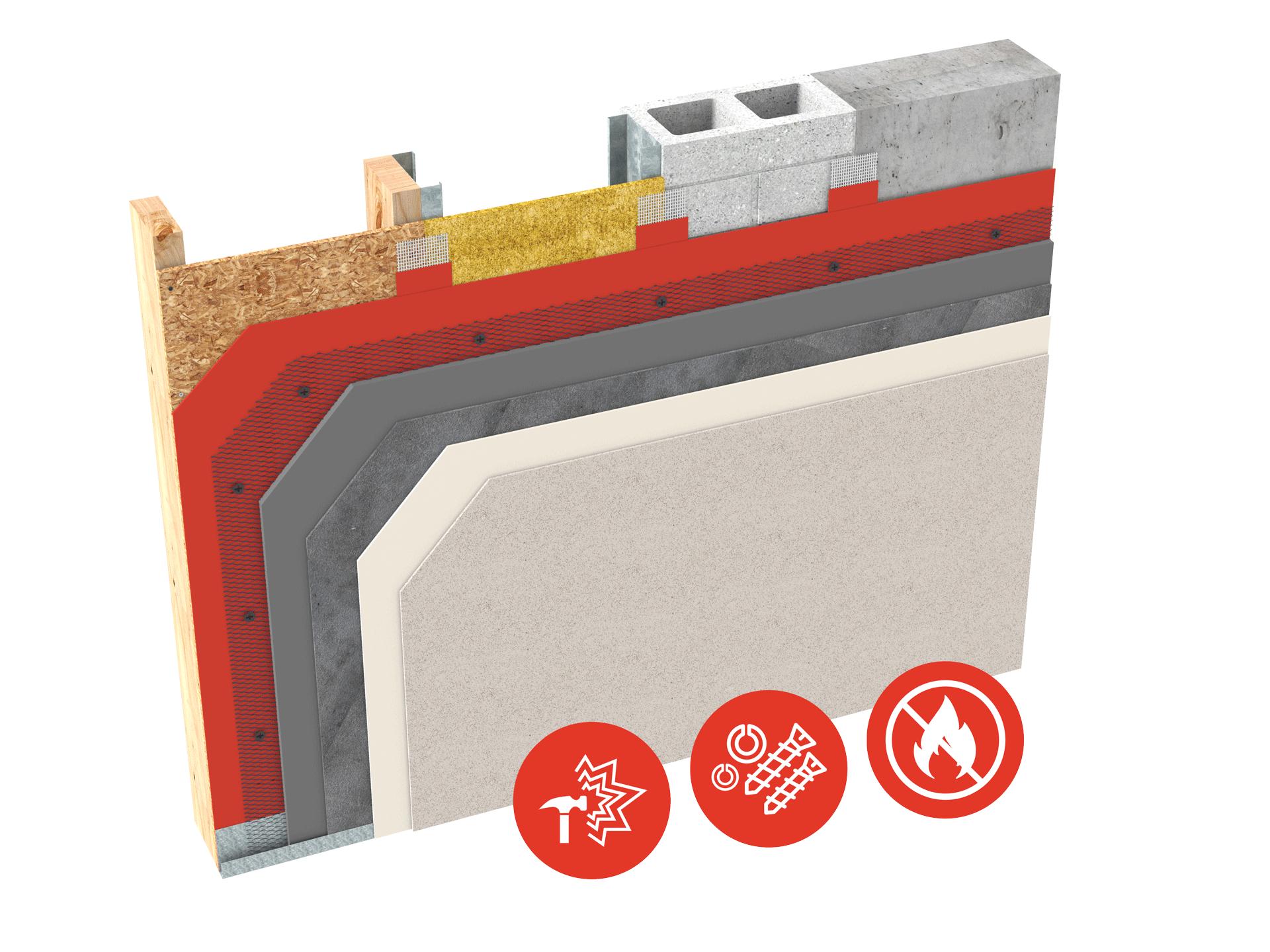

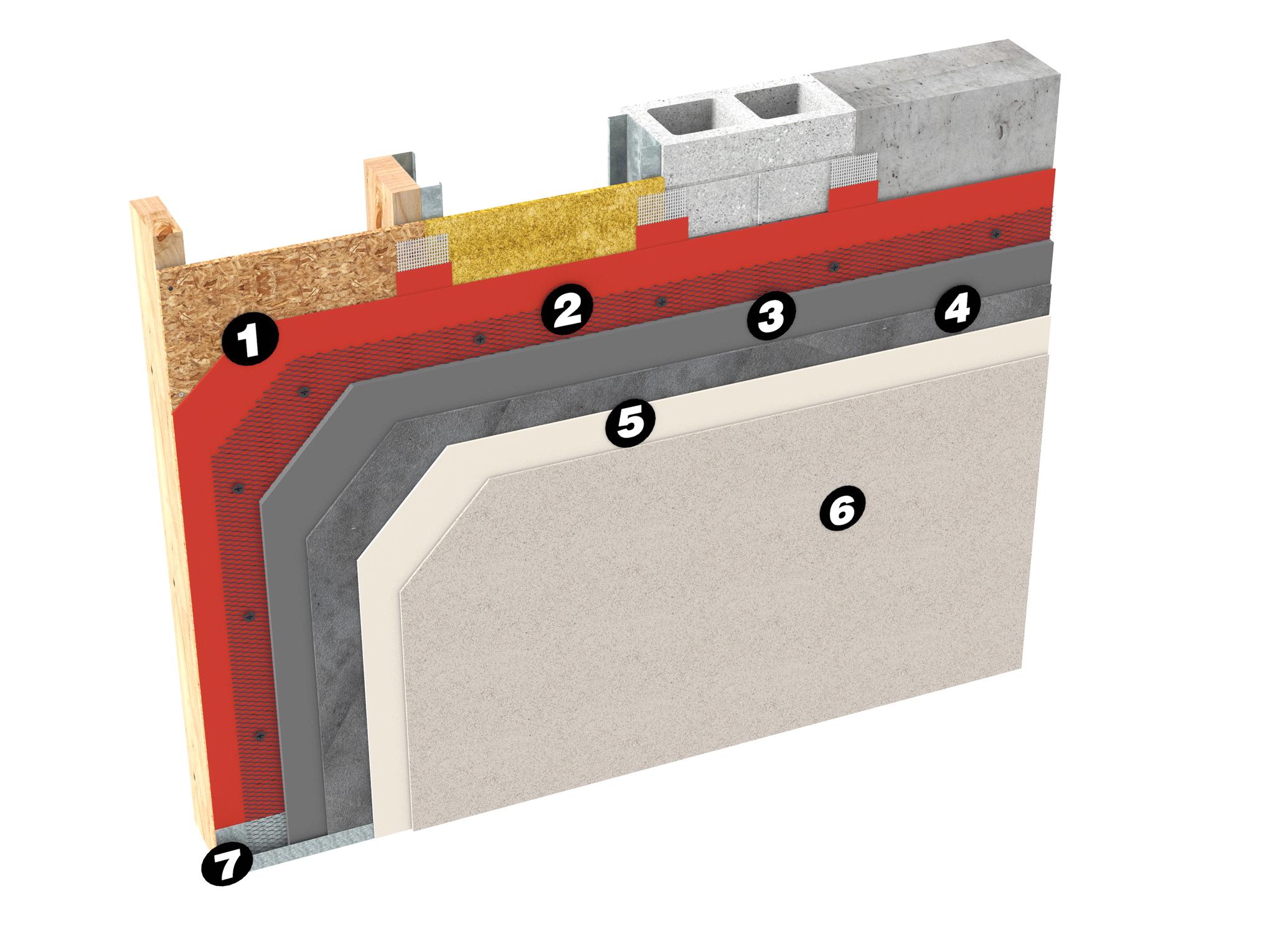

Stucco Wall is a non-insulated wall coating system. The system consists of a moisture barrier, reinforcing metal lath, trim accessories, scratch and base coats, and a finish texture coat which can be selected from any one of the available Durex® Architectural Coatings.

- High impact resistant

- Non-combustible

- Excellent for both new construction and retrofit work

Stucco Wall is an excellent system for both new and restoration work. It is suitable for use over all sound and solid substrates and can be used in all types of construction. It is the most popular system for use in residential applications.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 |

Non-Combustible stucco cladding |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| SUBSTRATE: | - Plywood - OSB (Oriented Strand Board) - Cementitious backer Board - Glass Mat Gypsum Sheathing - Concrete & Masonry |

CSA 0121 or 0151 or 0153 CSA 086 or 0325 ASTM C1325 ASTM C1177 |

12.7 mm (1/2”) min. 11 mm (7/16”) min. 12.7 mm (1/2”) min. 12.7 mm (1/2”) min |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers (consult with a Durabond Representative) Air Barriers Durex AirStop Durex Flexseal VP |

ASTM E96 Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B n/a n/a

185 ng/Pa.s.m2 505 ng/Pa.s.m2 629 ng/Pa.s.m2 972 ng/Pa.s.m2 |

| REINFORCEMENT: | Galvanized metal lath |

ASTM 525 |

Min. 1.36kg/m² |

| BASE COAT: | - Durex Uniplast / Acrylic Resin Bond - Durex Dryplast |

CAN/ULC S114 CAN/ULC S114 |

Rated noncombustible Rated noncombustible |

| FASTENERS: | -Durex “M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel) |

ASTM B-117 – salt spray DIN 50012 - SO2 exposure FM4470 DIN 50018 SFW |

750 hrs. or better 25+ cycles 30 cycles Pass |

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report #13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE: | Water Vapour Transmission |

ASTM E96 |

(refer to selected WRB / Air Barrier for respective water vapour permeance levels) |

Water absorption |

ASTM D570 |

1.9% Uniplast |

|

Coefficient of Water Absorption |

CCMC 5.5.1 |

0.0007 kg/(m2.s1/2) |

|

Tensile Strength |

ASTM C190 |

6.00 MPa (870 psi) |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Transition Membrane | ||

| Reinforcing Metal Lath | ||

| 2 Layers Base Coat | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard | ||

| Galvanized Trim |