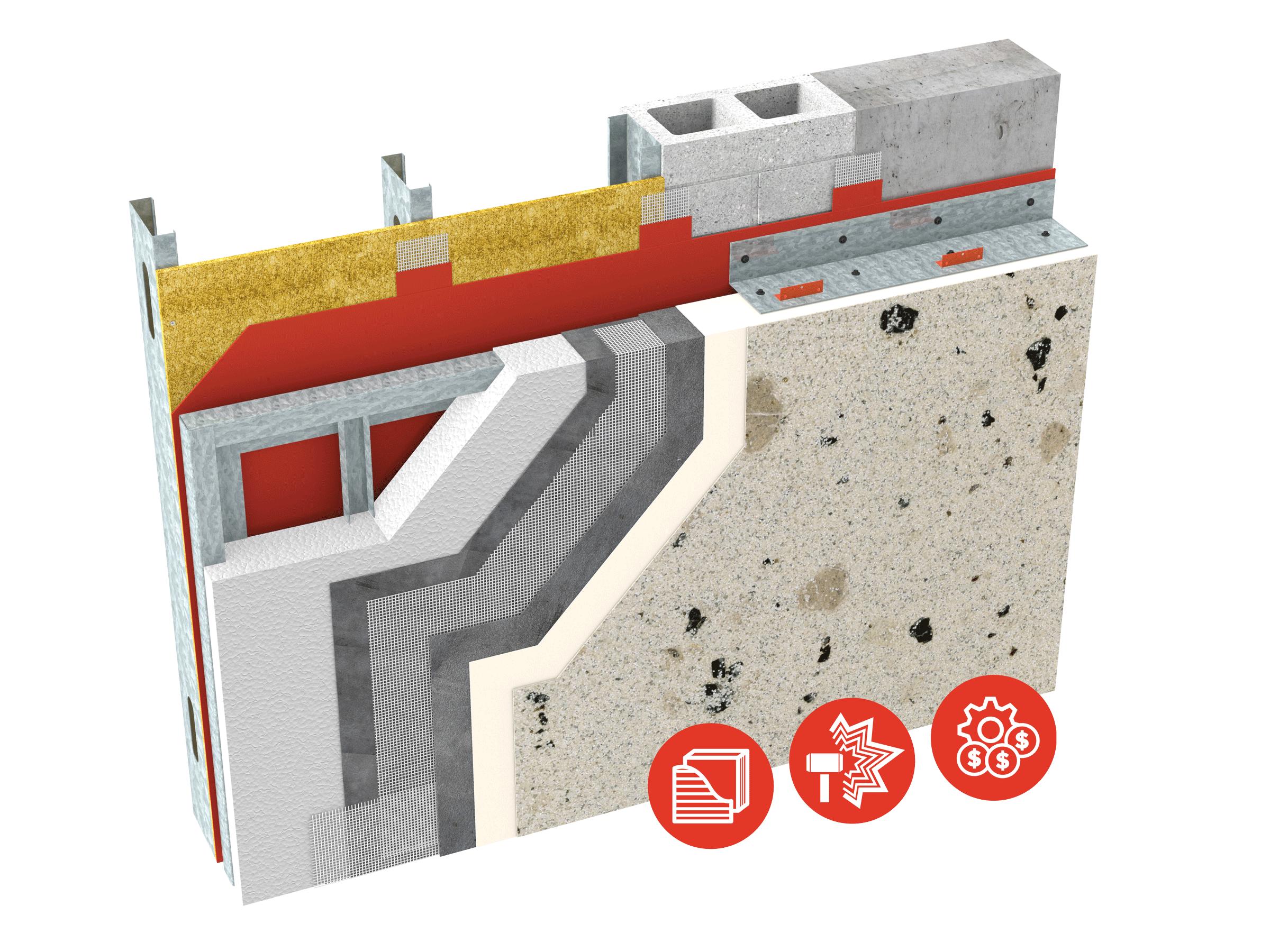

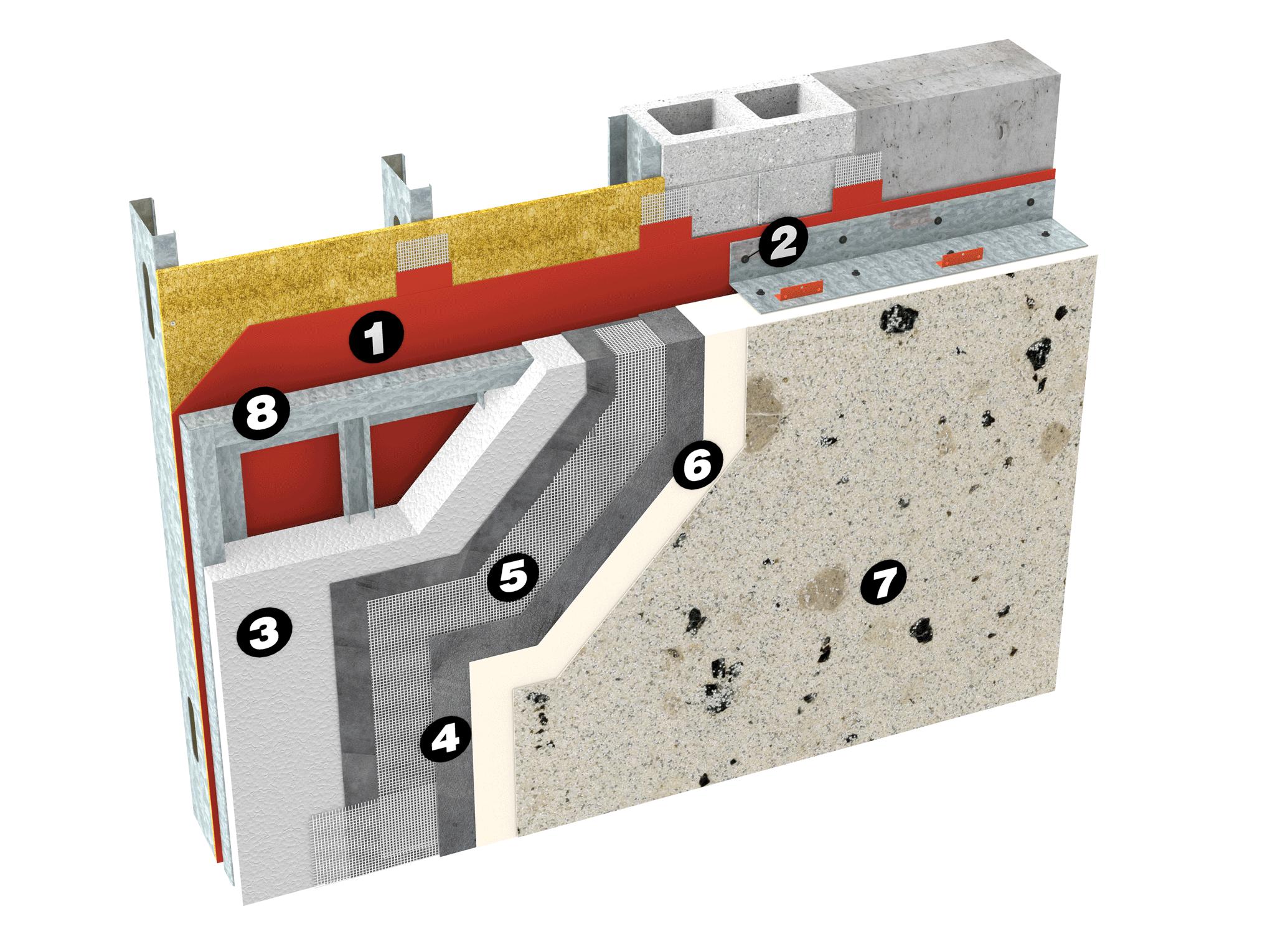

Panelite System is a prefabricated over-clad structural system. It consists of prefabrication of the EIFS portion inclusive of metal reinforcement inserts that are used to fasten the system to the structure.

- Cost effective cladding solution

- Higher deviation absorption

- Significant reduction of constrution time

- Lightweight

Panelite System is intended for use for new construction and retrofit - low, medium and high rise buildings.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 & CAN/ULC S101 CAN/ULC S134 |

Non-Combustible Lamina Fire Test of Exterior Wall Assemblies |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| INSULATION: |

Durex Quantum Select Type I Durex Quantum Select Type II Durex Equalite Select |

CAN/ULC S701

CAN/ULC S702 |

Thermal Resistance GDDC Factor 0.65 RSI (R 3.9) per inch 47% 0.70 RSI (R 4.0) per inch 47% 0.70 RSI (R 4.0) per inch 47% |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers Durex Flexseal Air Barriers Durex Flexseal VP Durex AirStop |

ASTM E96 –Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B 2.9 ng/Pa.s.m2

629 ng/Pa.s.m2 972 ng/Pa.s.m2 185 ng/Pa.s.m2 505 ng/Pa.s.m2 |

| PANEL ATTACHMENT: | -Durex“M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel) |

ASTM B-117 – salt spray DIN 50012 - SO2 exposure FM4470 & DIN 50018 SFW |

750 hrs. or better 25+ cycles 30 cycles Pass |

| LAMINA: | Impant Resistance Durex Fiberglass Mesh (Note: Impact resistance level is directly related to the weight and layers of Fiberglass mesh used in the lamina) |

ASTM E2486 – Impact Resistance (Refer to Table 1.5.9 of the Panelite Specifications for detailed selection chart for guidance on level of impact resistance required) |

Retention Retention Physical Performance Standard 3 N.m 10 N.m PASS Intermediate 8 N.m 15 N.m PASS High 13 N.m 20 N.m PASS Ultra High 20 N.m 30 N.m PASS Extreme 25 N.m 40 N.m PASS |

Base Coat Durex Uniplast/Acrybond “S” Durex Monobase |

CAN/ULC S114 Noncombustibility |

Rated Noncombustible Rated Noncombustible |

|

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report # 13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE: | Fire Protection |

(Refer CCMC Evaluation Report # 13103-R for complete detailed performance data) CAN/ULC S101 & CAN/ULC S114 (Compliance to NBC 3.2.3.8(1) (b) ) CAN/ULC S134 (Compliance to NBC 3.1.5.5) |

Rated as non-combustible cladding ULC design EW21/ EW22

Intertek listing # DPL-WEIFS 30-01 |

Wind Load Resistance |

ASTM E330 – sustained

ASTM E330 – cyclic ASTM E330 – blow-out

|

-2.5 kPa for 60min. – no visible damage to any of the wall components -600 cycles alt. 0 to -2.5kPa – no visible damage to any of the wall components -3.75kPa applied for 10 sec. – no visible damage to any of the wall components - max. pressure 7.12 kPa |

|

Water Tightness |

ASTM E331 |

400 Pa pressure difference for 15 min. – no water penetration through the exterior surface finish |

|

System Compliance |

CCMC Technical Guide for EIFS CAN/ULC S716.1 EIFS Materials & System |

CCMC Evaluation Report # 13103-R Durex Panelite is fully compliant with: -CAN/ULC S716.1 Materials & System -CAN/ULC S716.2 Installation of Components & WRB -CAN/ULC S716.3 Design Application |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Transition Membranes | ||

| Insulation Adhesives | ||

| Rigid Insulation (Exterior) | Attached with Approved Mechanical Fasteners Attached with Approved Mechanical Fasteners Attached with Approved Mechanical Fasteners Attached with Approved Mechanical Fasteners Attached with Approved Mechanical Fasteners Attached with Approved Mechanical Fasteners |

|

| Base Coat | ||

| Reinforcing Mesh | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard |