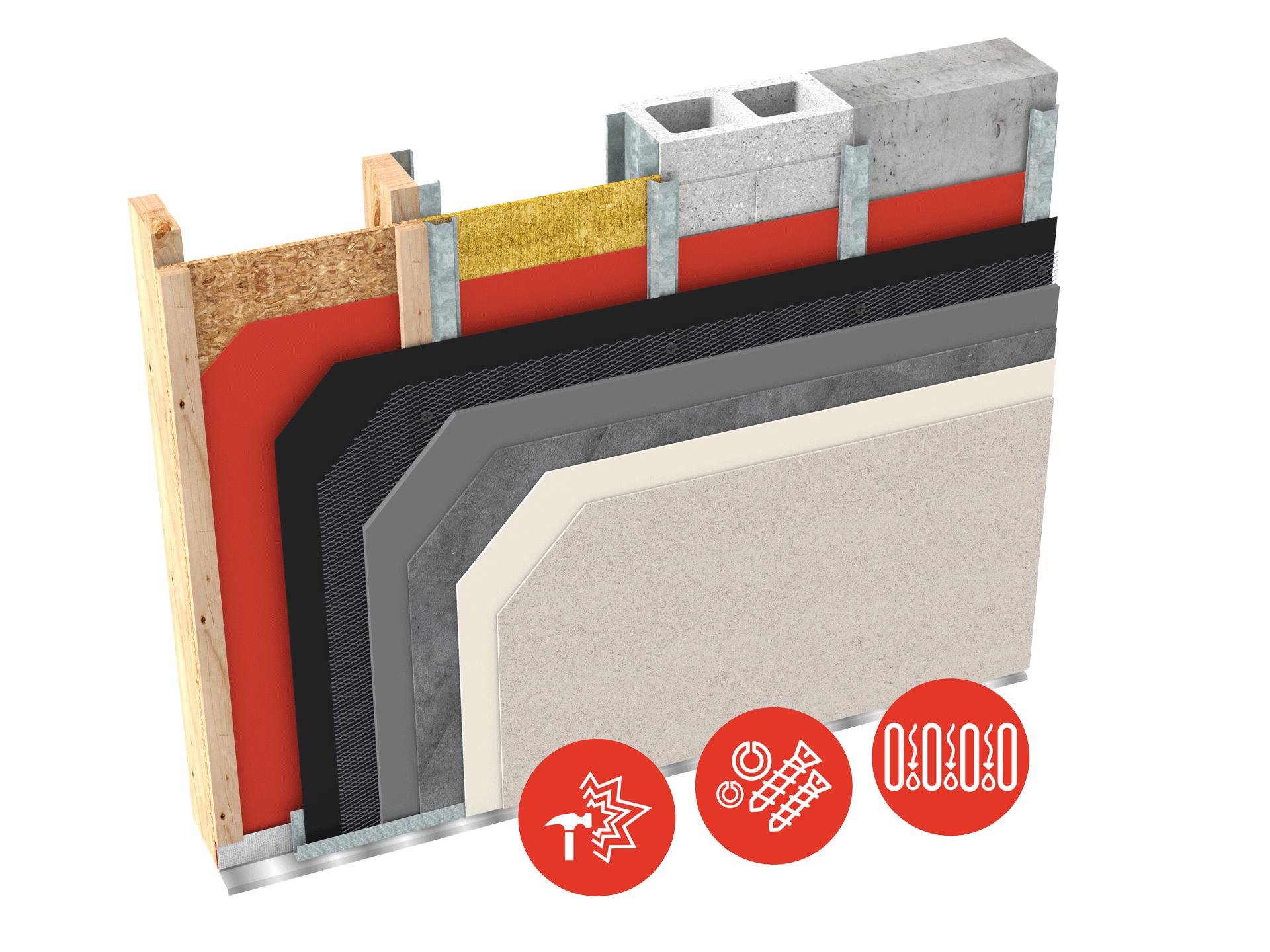

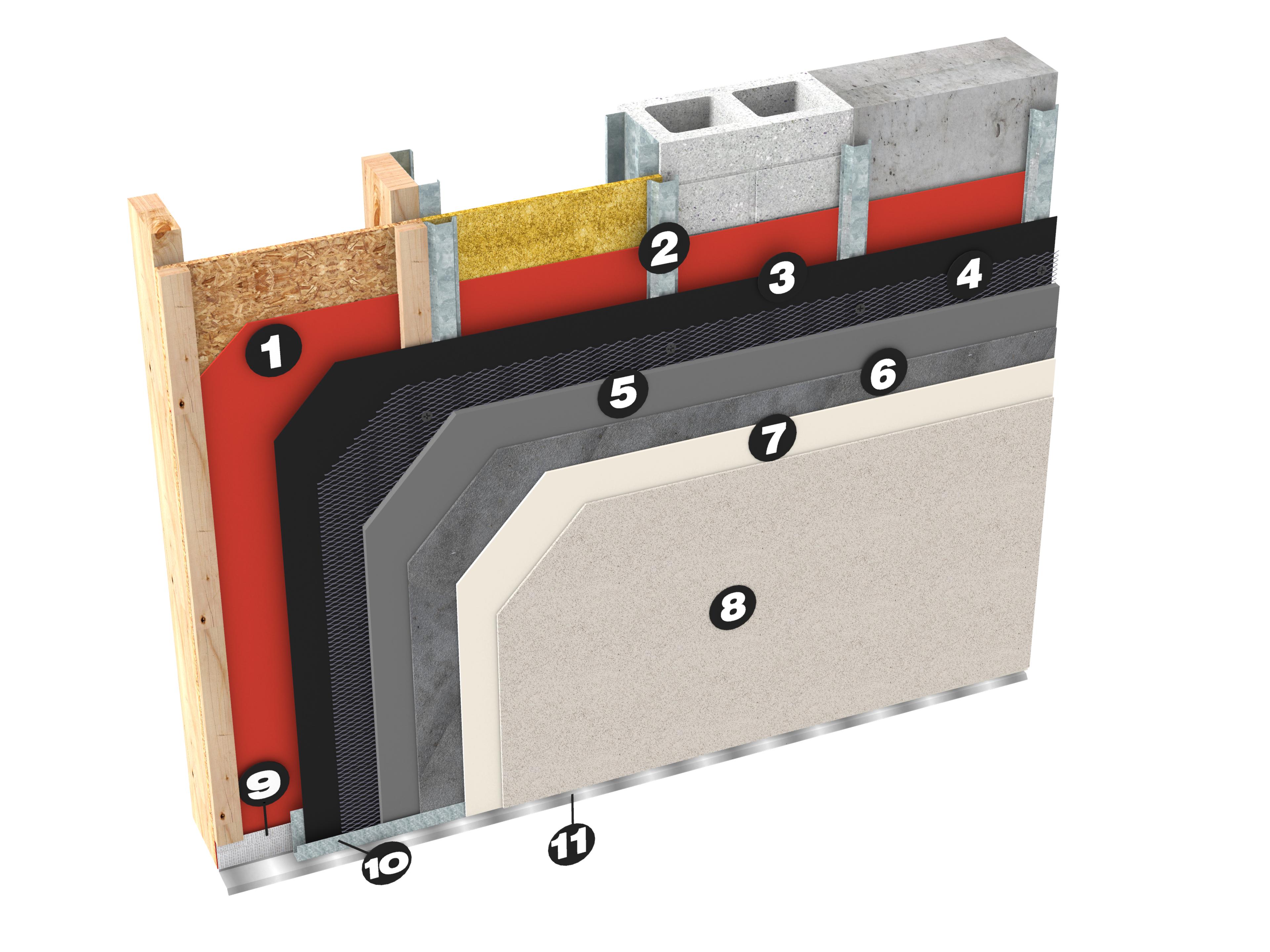

Stucco Wall Rainscreen is a traditional hard coat stucco system, consisting of polymer modified cement palster reinforced with galvanized metal lath, inclusive of a furring system to create a code compliant rainscreen drainage medium. The finish texture can be selected from any of the available Durex® Architectural Coatings. The cladding system is rated non-combustible cladding meeting the building code requirements for non-combustible construction.

- Traditional cladding system

- Positive drainage - rainscreen

- Non-combustible

- High impact resistance

Succo Wall Rainscreen is suitable for use over a wide range of structurally sound substrates. It is best suited for substrates designed with a deflection ratio lower than L/360.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 |

Non-Combustible stucco cladding |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| SUBSTRATE: | - Plywood - OSB (Oriented Strand Board) - Cementitious backer Board - Glass Mat Gypsum Sheathing - Concrete & Masonry |

CSA 0121 or 0151 or 0153 CSA 086 or 0325

ASTM C1325 ASTM C1177 |

12.7 mm (1/2”) min. 11 mm (7/16”) min.

12.7 mm (1/2”) min. 12.7 mm (1/2”) min. |

| WATER RESISTIVE BARRIER: | Air / Vapour Barriers (consult with a Durabond Representative) Air Barriers Durex AirStop Durex Flexseal VP |

ASTM E96 Water Vapour Transmission (Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B n/a n/a

185 ng/Pa.s.m2 505 ng/Pa.s.m2 629 ng/Pa.s.m2 972 ng/Pa.s.m2 |

| REINFORCEMENT: | Galvanized metal lath |

ASTM 525 |

Min. 1.36kg/m² |

| BASE COAT: | - Durex Uniplast / Acrylic Resin Bond - Durex Dryplast |

CAN/ULC S114 CAN/ULC S114 |

Rated noncombustible Rated noncombustible |

| FASTENERS: | -Durex “M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel) |

ASTM B-117 – salt spray DIN 50012 - SO2 exposure FM4470 DIN 50018 SFW |

750 hrs. or better 25+ cycles 30 cycles Pass |

| FINISHES: | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R (Refer to product specific Technical Data Sheet and CCMC Evaluation Report #13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE: | Water Vapour Transmission |

ASTM E96 - |

(refer to selected WRB / Air Barrier for respective water vapour permeance levels) |

Water absorption |

ASTM D570 |

1.9% Uniplast |

|

Tensile Strength |

ASTM C190 |

6.00 MPa (870 psi) |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Bracing | ||

| Building Paper with Reinforced Metal Lath | ||

| Cement Board | ||

| 2 Layers Base Coat | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes - Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard | ||

| Transition Membrane | ||

| Galvanized Trim | ||

| Flashing |