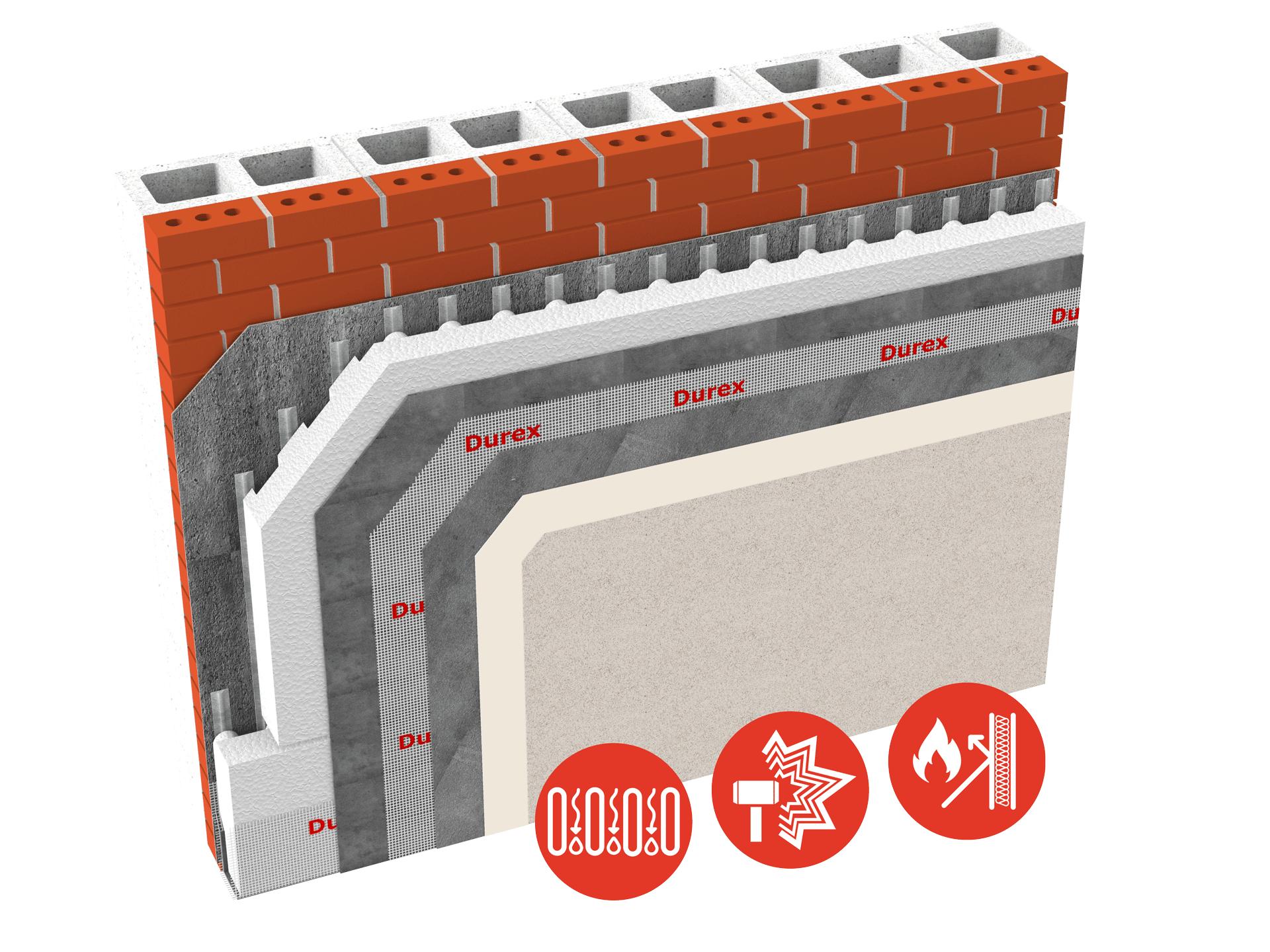

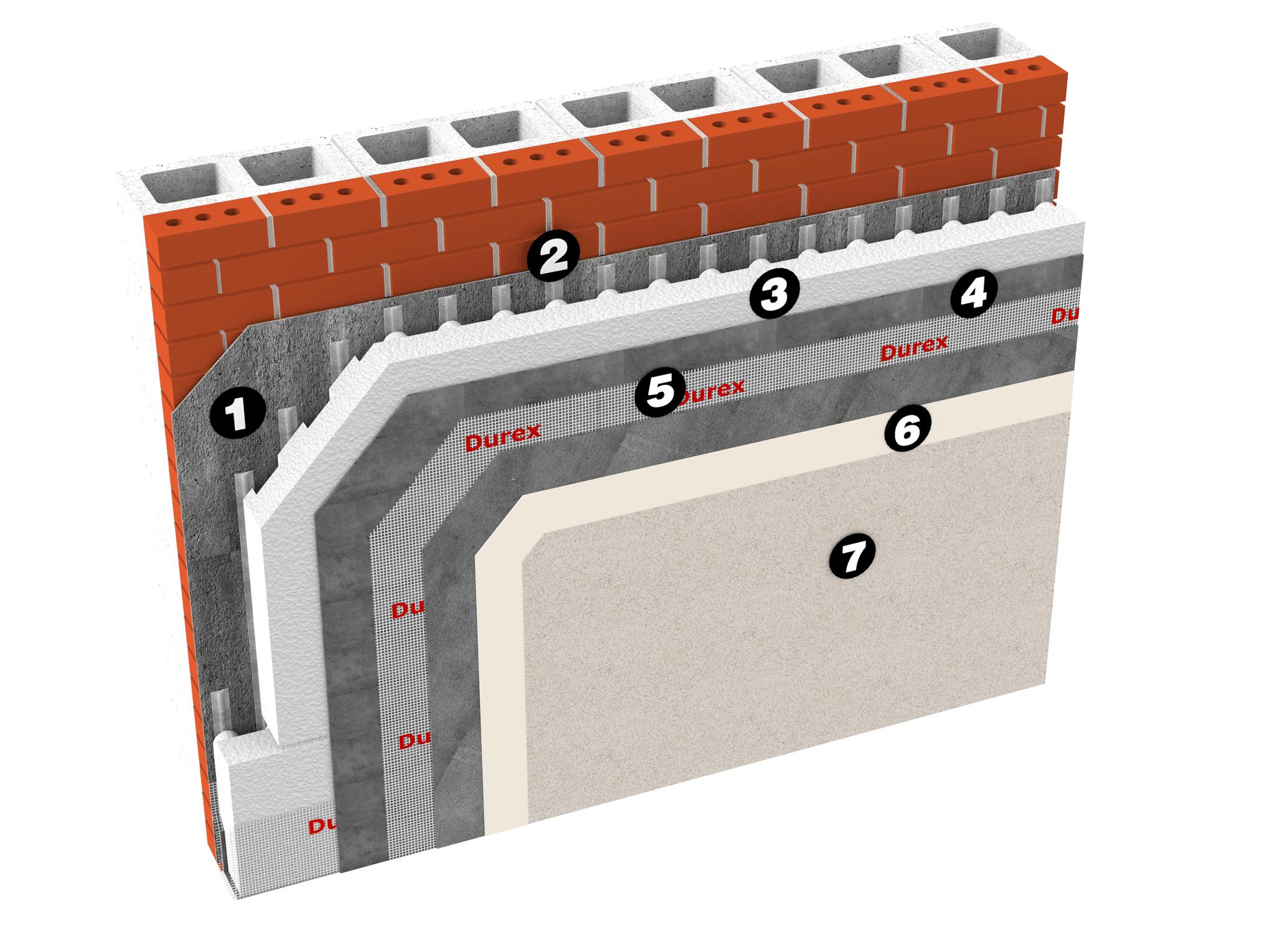

Quantum Select Overclad has been specially designed to facilitate the recladding of existing buildings by substantially upgrading the thermal efficiency of the building envelope while encorporating the ideal moisture mamanement drainage system. All in all, the best most cost effective method for the retrofit of existing midrise and highrise aging buildings. The aesthetics of the building can be further enhanced by a finish texture coat which can be selected from any one of the available Durex® Architectural Coatings. Quantum Select Overclad system is ULC rated as non-combustible cladding meeting building code requirements for non-combustible construction. It can be installed by adhesive, mechanichal fasteners or a combination of both.

- CCMC listed (13103-R)

- Continuous venting at floor lines and horizontal terminations, using pre-manufactured vented boards

- Positive drainage (through a network of vertical and horizontal channels)

- Continuous air/vapour barrier

- Simple interfacing with other pressure equalized claddings

- 2-hour fire rating in accordance with ULC W-456

- Aesthetic design flexibility

- GDDC Factor 47% (Geometrically Defined Drainage Cavity)

- CI factor 0.65 RSI (R 3.9) per inch (Continuous Insulation)

- CI factor 0.70 RSI (R 4.0) per inch Type II EPS (Continuous Insulation)

Quantum Select Overclad is ideally designed for the restoration of existing masonry clad buildings that require an upgrade of its building envelope. It is equally suitable for use over a wide range of structurally sound or questionable substrates and is recommended for use in buildings which require moisture managed cladding.

| Building Code Conformance | Classification |

Category 1 CAN/ULC S114 & CAN/ULC S101 CAN/ULC S134 |

Non-Combustible Lamina Fire Test of Exterior Wall Assemblies |

Part 3 |

|

|

|

Part 5 |

|

|

|

Part 9 |

|

|

|

| INSULATION | Durex Quantum Select Type I Durex Quantum Select Type II |

CAN/ULC S701 |

Thermal Resistance GDDC Factor 0.65 RSI (R 3.9) per inch 47% 0.70 RSI (R 4.0) per inch 47% |

| WATER RESISTIVE BARRIER | Air / Vapour Barriers Durex Flexseal Durex Ectoflex Air Barriers Durex Flexseal VP Durex AirStop Durex Flexcrete |

ASTM E96 – Water Vapour Transmission

(Refer to product specific Technical Data Sheet for more detailed data) |

Method A Method B 2.9 ng/Pa.s.m2 18 ng/Pa.s.m2 91 ng/Pa.s.m2

629 ng/Pa.s.m2 972 ng/Pa.s.m2 185 ng/Pa.s.m2 505 ng/Pa.s.m2 400 ng/Pa.s.m2 972 ng/Pa.s.m2 |

| INSULATION ATTACHMENT |

-Durex“M” fasteners (masonry) -Durex “W” fasteners (wood) -Durex “S” fasteners (steel)

Durex Flexcrete Durex Monobase Durex VCA 3.0 |

Mechanical Attachment: ASTM B-117 – salt spray DIN 50012 - SO? exposure FM4470 & DIN 50018 SFW Adhesive Attachment: ASTM D1623 Adhesion Properties (Refer to product specific Technical Data Sheet for more detailed data) |

750 hrs. or better 25+ cycles 30 cycles Pass

1.12 MPa (162 psi) 1.38 MPa (200 psi) 1.02 MPa (148 psi) |

| LAMINA | Impant Resistance Durex Fiberglass Mesh (Note: Impact resistance level is directly related to the weight and layers of Fiberglass mesh used in the lamina) |

ASTM E2486 – Impact Resistance

(Refer to Table 1.5.9 of the Quantum Select OVERCLAD Specifications for detailed selection chart for guidance on level of impact resistance required) |

Retention Retention Physical Performance Standard 3 N.m 10 N.m PASS Intermediate 8 N.m 15 N.m PASS High 13 N.m 20 N.m PASS Ultra High 20 N.m 30 N.m PASS Extreme 25 N.m 40 N.m PASS |

| Base Coat | Durex Uniplast/Acrybond “S” Durex Monobase |

CAN/ULC S114 Noncombustibility |

Rated Noncombustible Rated Noncombustible |

| FINISHES | Durex Architectural Coatings Classic Series Premium Series Artisan Series Kolor Gard Series Elastomeric (FX) Series |

CAN/ULC S716.1 & CCMC Report # 13103-R

(Refer to product specific Technical Data Sheet and CCMC Evaluation Report #13103-R for more detailed data) |

Durex Architectural Coatings Meet and exceed all requirements |

| PERFORMANCE | Fire Protection |

CAN/ULC S101 & CAN/ULC S114 (Compliance to NBC 3.2.3.8(1) (b) )

CAN/ULC S101 (Fire Resistance rated Assemblies)

CAN/ULC S134 (Compliance to NBC 3.1.5.5) |

Rated as non-combustible cladding ULC design EW21/ EW22

1 hr. FR rating ULC design W489 (Load Bearing) 2 hrs. FR rating ULC design W485 (Load Bearing) 2 hrs. FR rating ULC design W456 (Non-Load Bearing)

Intertek listing # DPL-WEIFS 30-01 |

Wind Load Resistance |

ASTM E330 – sustained ASTM E330 – cyclic

ASTM E330 – blow-out |

-2.5 kPa for 60min. – no visible damage to any of the wall components 600 cycles alt. 0 to -2.5kPa – no visible damage to any of the wall components -3.75kPa applied for 10 sec. – no visible damage to any of the wall components - max. pressure 7.12 kPa |

|

Water Tightness |

ASTM E331 |

400 Pa pressure difference for 15 min. – no water penetration through the exterior surface finish |

|

System Compliance |

CCMC Technical Guide for EIFS CAN/ULC S716.1 EIFS Materials & System |

CCMC Evaluation Report # 13103-R Durex Quantum Select OVERCLAD is fully compliant with: CAN/ULC S716.1 Materials & System CAN/ULC S716.2 Installation of Components & WRB CAN/ULC S716.3 Design Application |

| System Layer | Optional Products Per Layer | Notes |

|---|---|---|

| Water Resistive Barriers (WRB) | ||

| Transition Membrane | ||

| Insulation Adhesive | ||

| Rigid Insulation (Exterior) | ||

| Base Coat | ||

| Reinforcing Mesh | ||

| Primers | ||

| Finishes - Classic Series | ||

| Finishes _ Premium Series | ||

| Finishes - Artisan Series | ||

| Finishes - Flexible Series | ||

| Finishes - Kolor Gard |