88-130 ft2/gal @ 12-18 mils DFT

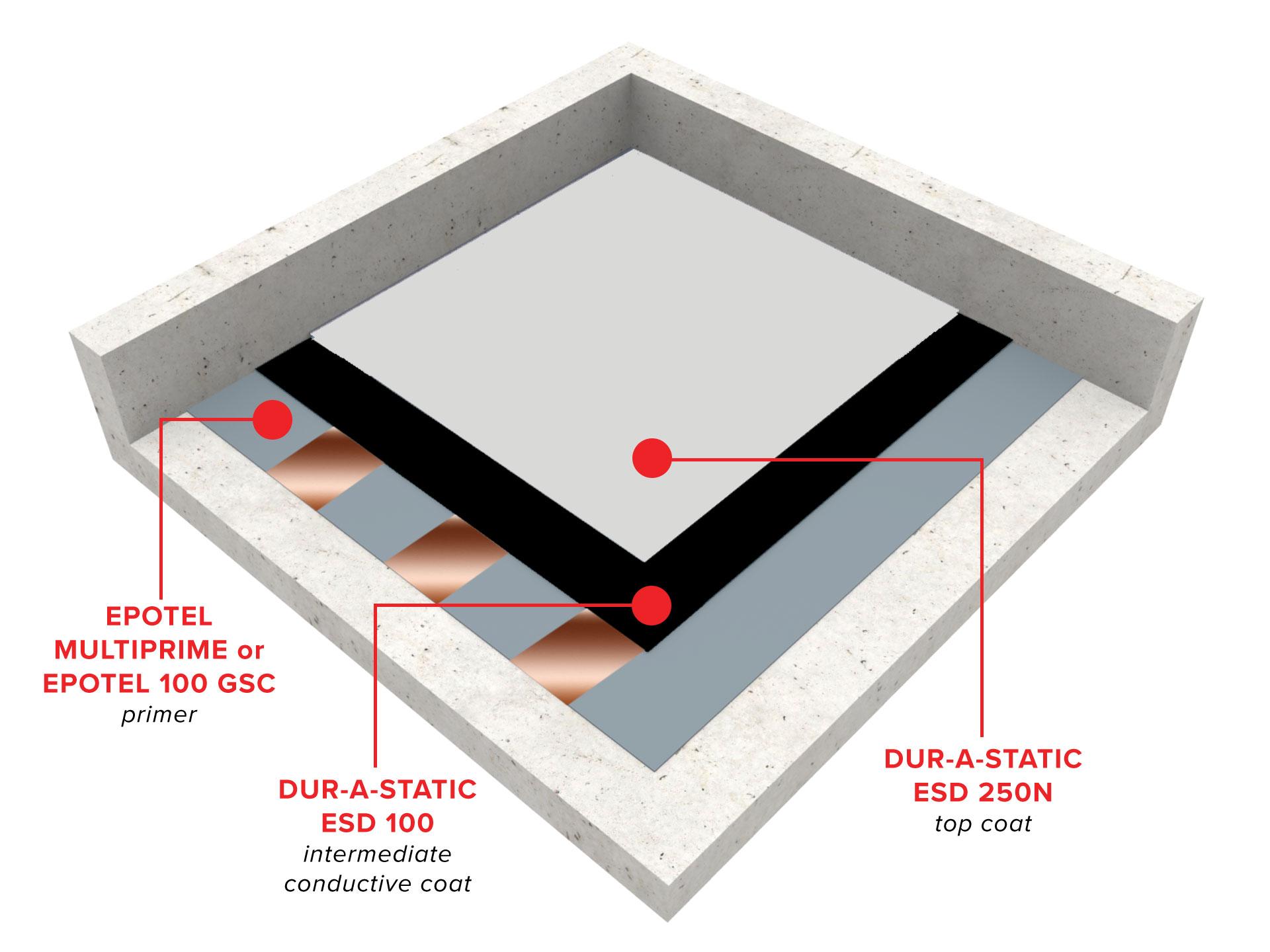

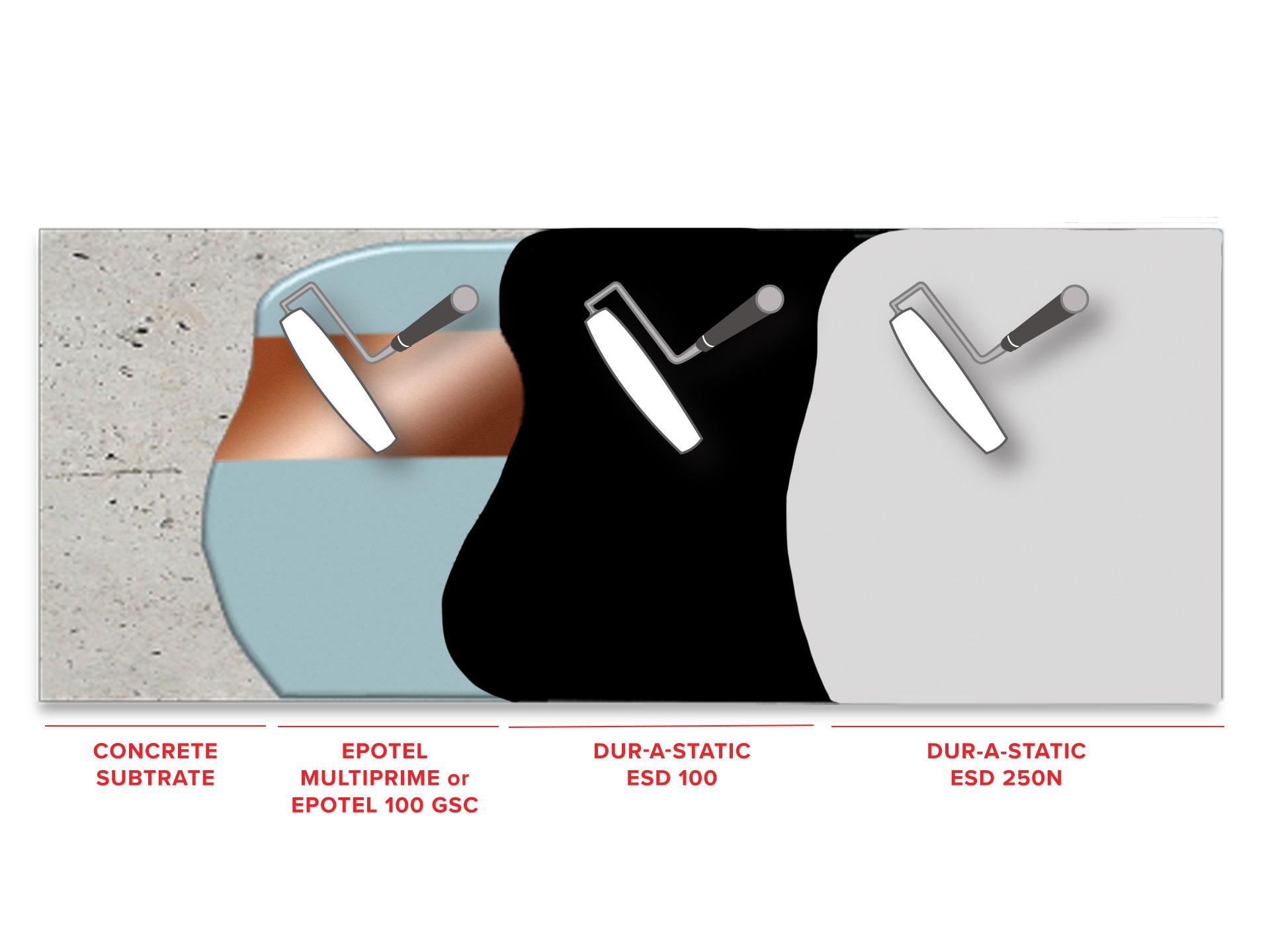

Durex Dur-A-Static ESD 250N is a highly chemical resistant, Novolac epoxy-based ESD coating designed as the top coat for Durex Dur-A-Static electrostatic discharge (ESD) flooring system. Durex Dur-A-Static ESD 250N is designed for use as a highly chemical resistant, wear-resistant top coat in a static dissipative system that provides electric conductive resistance to protect sensitive electronic equipment and machinery. The system performs to a range of 2.5 x 104 to 1.0 x 106 ohms. The system consists of a priming/leveling layer which is then combined with conductive grounded copper wire, Durex Dur-A-Static ESD 100 intermediate conductive coat and Durex Dur-A-Static 250N Top Coat.

- Protects sensitive electronic parts from the effects of static charges by dissipating them away

- Prevents explosions due to sparks of accumulated static charges by effectively conducting it away

- Avoid errors in readings recorded by sensitive electronic instruments monitoring vital parameters

- Enables easy maintenance of clean room environment through its seamless, pore-free smooth surface

- Improves the working environment by its pleasant aesthetics

- Conforms to ANSI S20.20, < 3.5 x 107 ohms when tested in accordance with ANSI STM 97.1

- Available in conductive range (2.5 X 104 to 1.0 X 106) ohms per ANSI/ESD S7.1/ASTM F-150

- Low BVG, Body Voltage Generation

- Maintain electrical resistance throughout coating thickness

Durex Dur-A-Static ESD 250N is the chemical-resistant top coat layer for Durex Dur-A-Static ESD 250N Electrostatic Discharge (ESD) flooring system to provide electrostatic control properties to concrete and other construction substrates. The system is recommended for floors in environments where static electricity and stray currents produced by friction could pose risks of explosions or interference with the working of precision electronic instruments.

| Colour | Please see Durex® Colour Selection Guide for available colour options | |

| Resin Type | Cyclo-aliphatic Epoxy | |

| Mix Ratio |

| |

| Coverage | 88-130 ft2/gal @ 12-18 mils DFT | |

| Cure Time @ 23°C |

| |

| Pot Life @ 23°C | 20 minutes | |

| Recommended Film Thickness | 12-18 mils DFT |

| Method | Results | |

|---|---|---|

| Percent Solids | ASTM D7232-06 | 100% |

| V.O.C | ASTM D3960 | ≤ 15 g/L |

| Specific Gravity (Mixed) | ASTM D333 | 1.25 ± 0.05 g/L |

| Viscosity (Brookfield, 23°C) | ASTM D2196 | 1000 cps |

| Abrasion Resistance |

|

|

| Tensile Strength | ASTM D638-86 | 6,000 psi |

| Compressive Strength | ASTM C579 | 11,250N psi |

| Adhesion to Concrete | ASTM D4541 | > 350 Psi Concrete fails |

| Shore D Hardness | ASTM D2240 | 80 |