4 m2/L (160 ft2/gal) @ 10 mils DFT – Varies depending on System

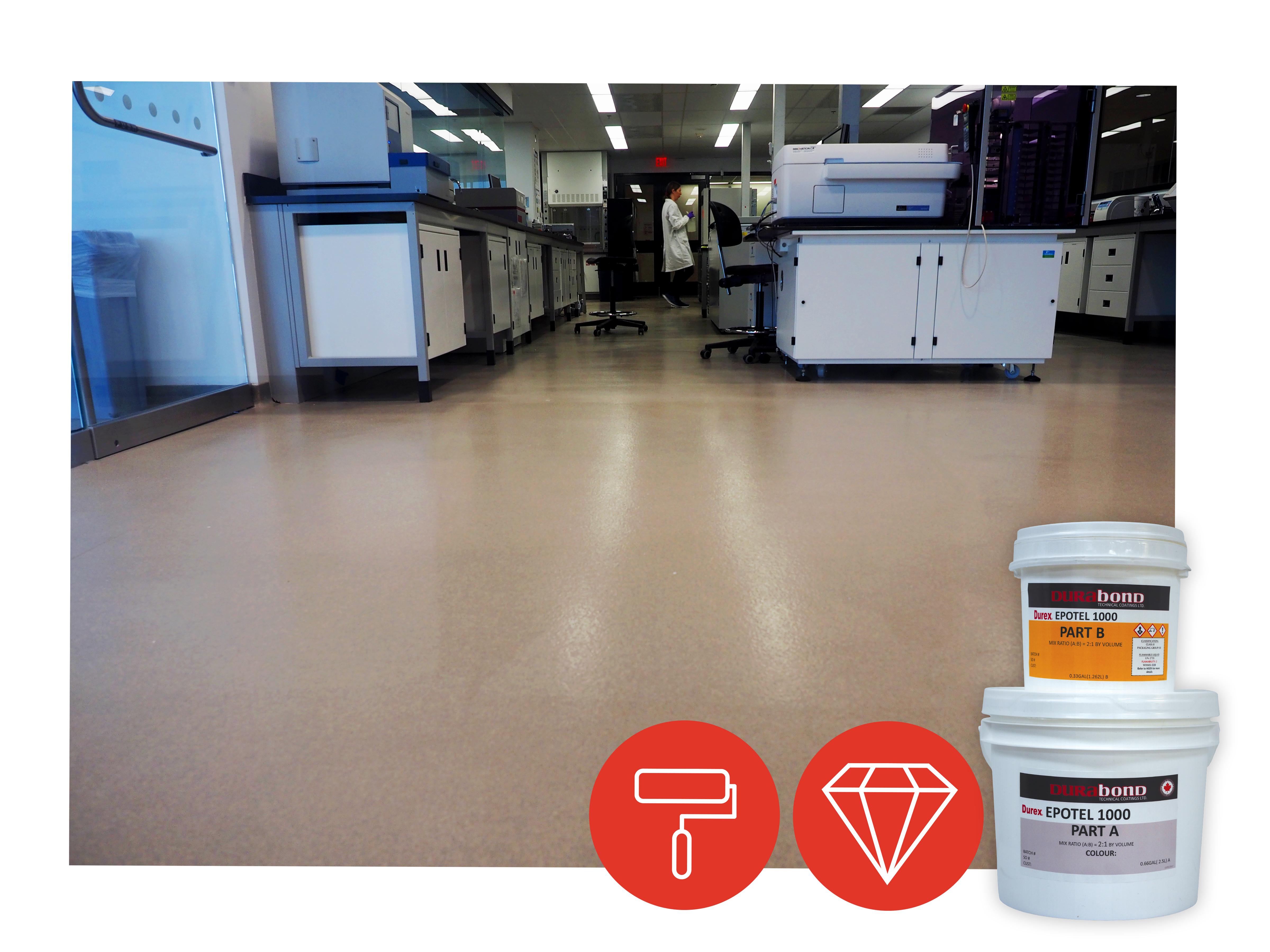

Epotel 1000 is superior quality, water clear, 100% solid, low odour, low VOC and high gloss epoxy binder and top coat. Durex® Epotel 1000 is design to use for Durex decorative system as binder and top coat where highest level of aesthetics is required. Epotel 1000 is resistant to changes in clarity, making it ideal for decorative flooring applications. Epotel 1000 is to be used for a variety of decorative systems such as Dur-A-Metallic, Dur-A-Quartz, Dur-A-Flake, Dur-A-Glitter and Dur-A-Granit systems.

- Water clear

- Self-leveling and seamless

- Self-priming

- Slower curing, easy to use

- Good hardness

- Good chemical and solvent resistance

- Excellent adhesion

- Very low odour

- Blushing-free properties

- Low viscosity

- Good resistance to yellowing

- Formulated using high-quality resins: Bisphenol A/F Epoxy / Cycloaliphatic Amine

Epotel 1000 is used as a clear binder and high-performance epoxy topcoat in decorative floor system applications. The excellent clarity and clarity retention makes it idea to be used in conjunction with flooring systems that utilize decorative quartz, flake, metallic and like elements.

| Colour | Clear | |

| Coverage | 4 m2/L (160 ft2/gal) @ 10 mils DFT – Varies depending on System | |

| Cure Time @ 23°C (75°F), 55% RH | To touch: 10 hours Light traffic: 12 hours Fully cured: 72 hours | |

| Recommended Film Thicknes | 10-20 mils DFT - Varies depending on System | |

| Mix Ratio |

| |

| Pot Life @ 23°C (75°F) | 30 – 35 minutes | |

| Reducer/Clean-up | Lacquer thinner or xylene |

| Method | Results | |

|---|---|---|

| Percent Solids | ASTM D7232-06 | 100% (volume – clear) |

| Viscosity (Brookfield) 23°C (75°F), A+B | ASTM D2196 | 500 cps Clear |

| V.O.C | ASTM D3960-05 | Zero |

| Specific Gravity (Part A + B) | ASTM D333 |

|

| Compressive Strength | ASTM 695-85 | 8,500 psi (58.6) MPa) |

| Tensile Strength | ASTM 695-85 | 1,850 psi (12.8 MPa) |

| Tensile Modulus | ASTM D638-86 | 480 psi (12.8 MPa) |

| Elongation | ASTM D638-86 | 8.0% |

| Flexural Modulus | ASTM D790-86 | 490 psi (3.4 MPa) |

| Abrasion Resistance | ASTM D4060-90 | 0.030g loss |

| Mar Resistance | ASTM D5178-91 | 1.0 kg |

| Shore D Hardness | 75 |