Acrutel-100 High-Performance UV-Resistant Polyurethane Flooring Topcoat is an aliphatic, water-based, thin-build, liquid-applied urethane coating. This highly durable, high performing formulation offers excellent abrasion and UV resistance for colour and gloss stability for decorative resinous flooring and wall systems.

- Water-based, aliphatic polyurethane, easy to apply

- Meets requirements of CFIA and USDA for food manufacturing facilities

- Resistant to weathering and colour fade by UV rays

- Wide-service temperature range

- Excellent abrasion and impact resistance

- Good flow and leveling properties for finishing

- Non-staining chemical resistance

- Available in different finishes: Gloss, Semi-gloss, Satin and Matte

- Available in non-slip additive

- Low VOC, Low Odour.

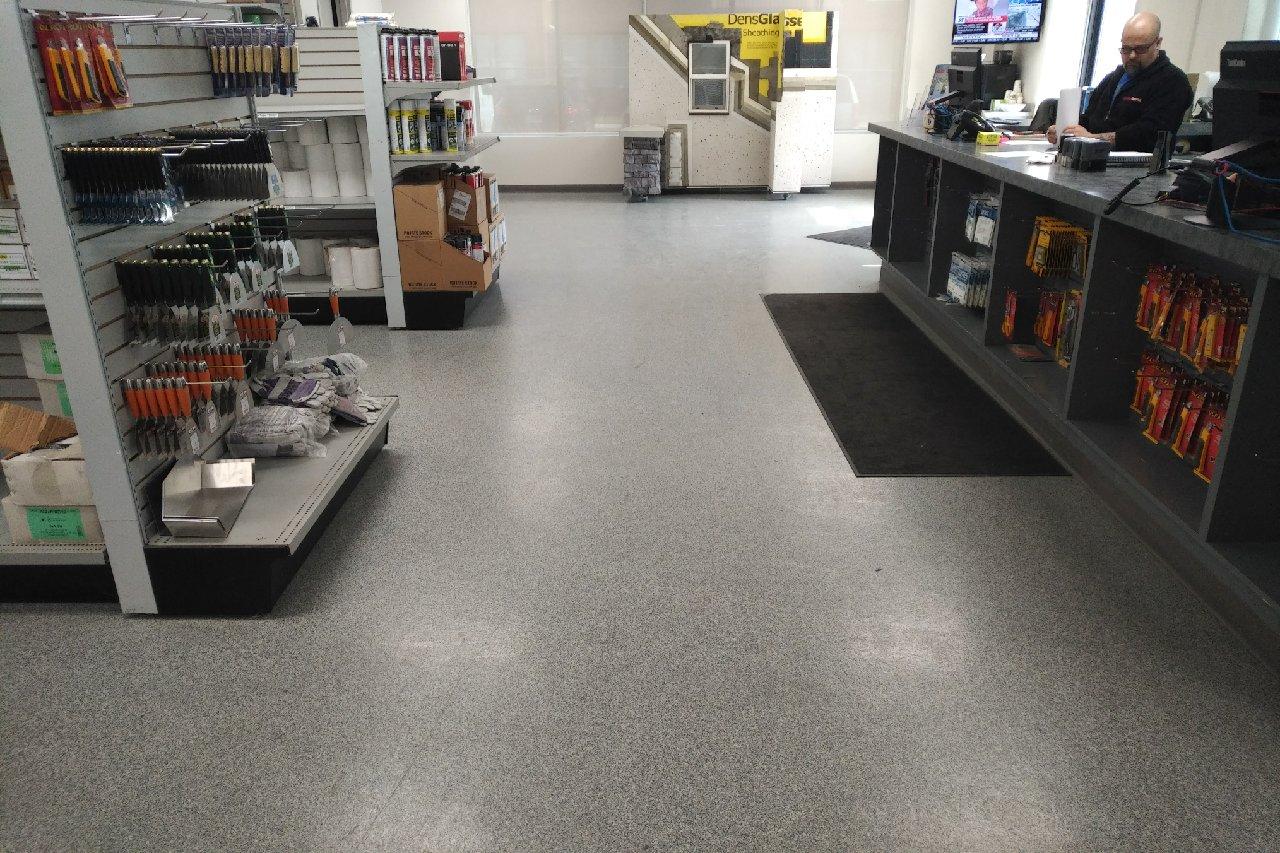

Acrutel-100 High-Performance UV-Resistant Polyurethane Flooring Topcoat is a roller-applied protective topcoat used in a wide range of institutional, commercial and industrial floor applications where long-term durability, UV and abrasion resistance is required.

| Colour | Pigmented (Finishes: Gloss, Matte, Dead Flat) | |

| Resin Type | Aliphatic Urethane/Acrylic | |

| Coverage |

| |

| Cure Time @ 23°C (75°F) |

| |

| Pot Life | 2 hours | |

| Mixing Ratio | 6:1 | |

| V.O.C. | < 65 g/L |

| Method | Results | |

|---|---|---|

| Percent Solids | ASTM D7232-06 | 48 ± 5% (vol.) |

| Viscosity (Brookfield) 23°C (75°F) | ASTM D2196 | 500 cps |

| Abrasion Resistance | ASTM D4060-01 |

|

| Hardness (Pencil) | ASTM D3363 | 2H |

| Hot Water Immersion | ASTM D870 | Pass – no blisters after 500 hours @ 38°C (100°F) |

| QUV Weathering | ASTM G 154 CYCLE 7 | Complete Pass 1000 hours |

| Sheen (60°) | ASTM D3679 |

|

| Specific Gravity | ASTM D333 |

|

| Coefficient of Friction | ANSI A137.1 Section 9.6.1. (BOT 3000E) |

|